Prism for total station

An instrument prism and prism technology, applied in the field of distance, level and azimuth measurement, can solve the problems of high operator skill and patience, prone to accidental errors, unfavorable accuracy, etc., to achieve good economic benefits, avoid accidental errors, and facilitate The effect of transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

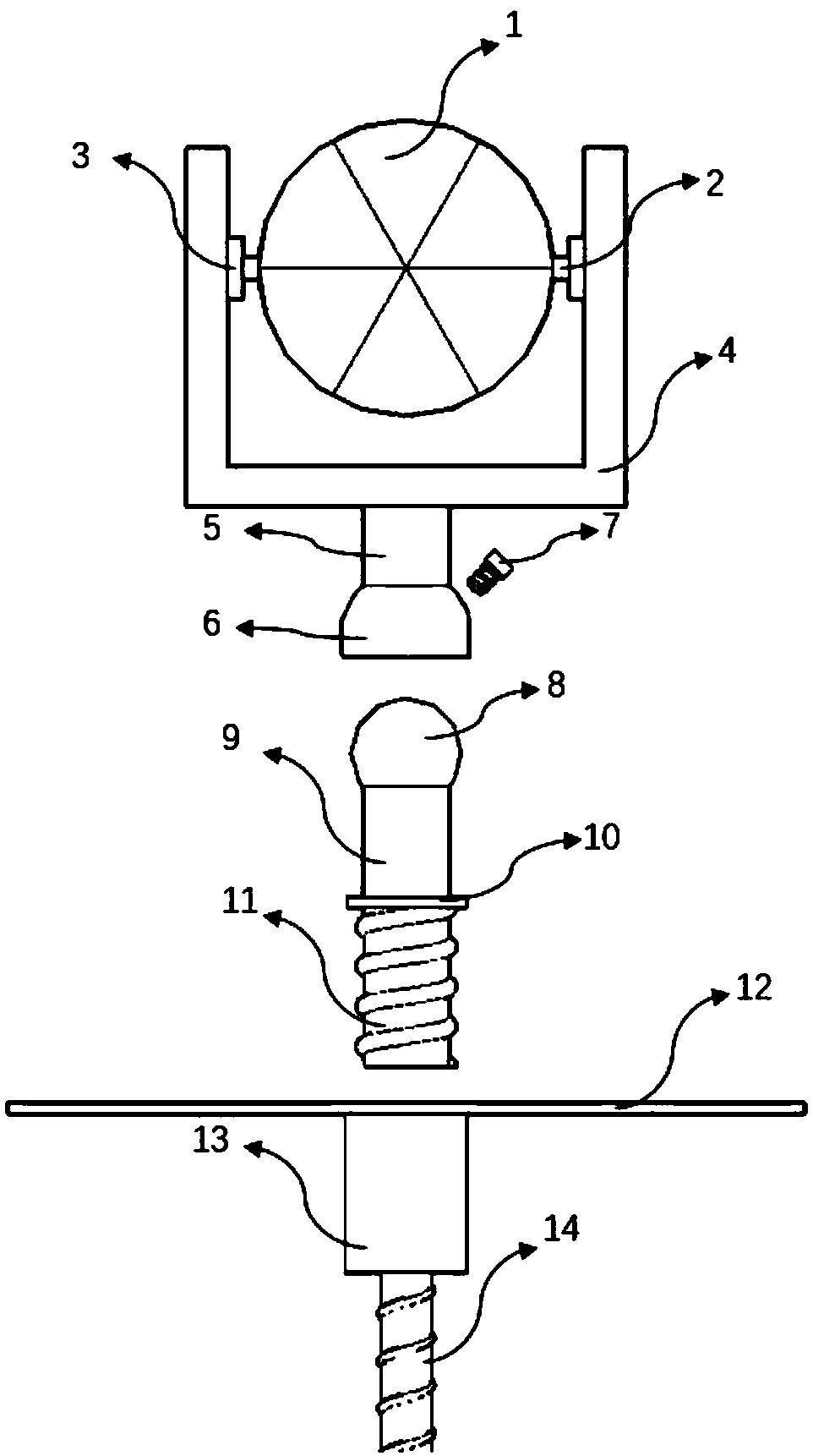

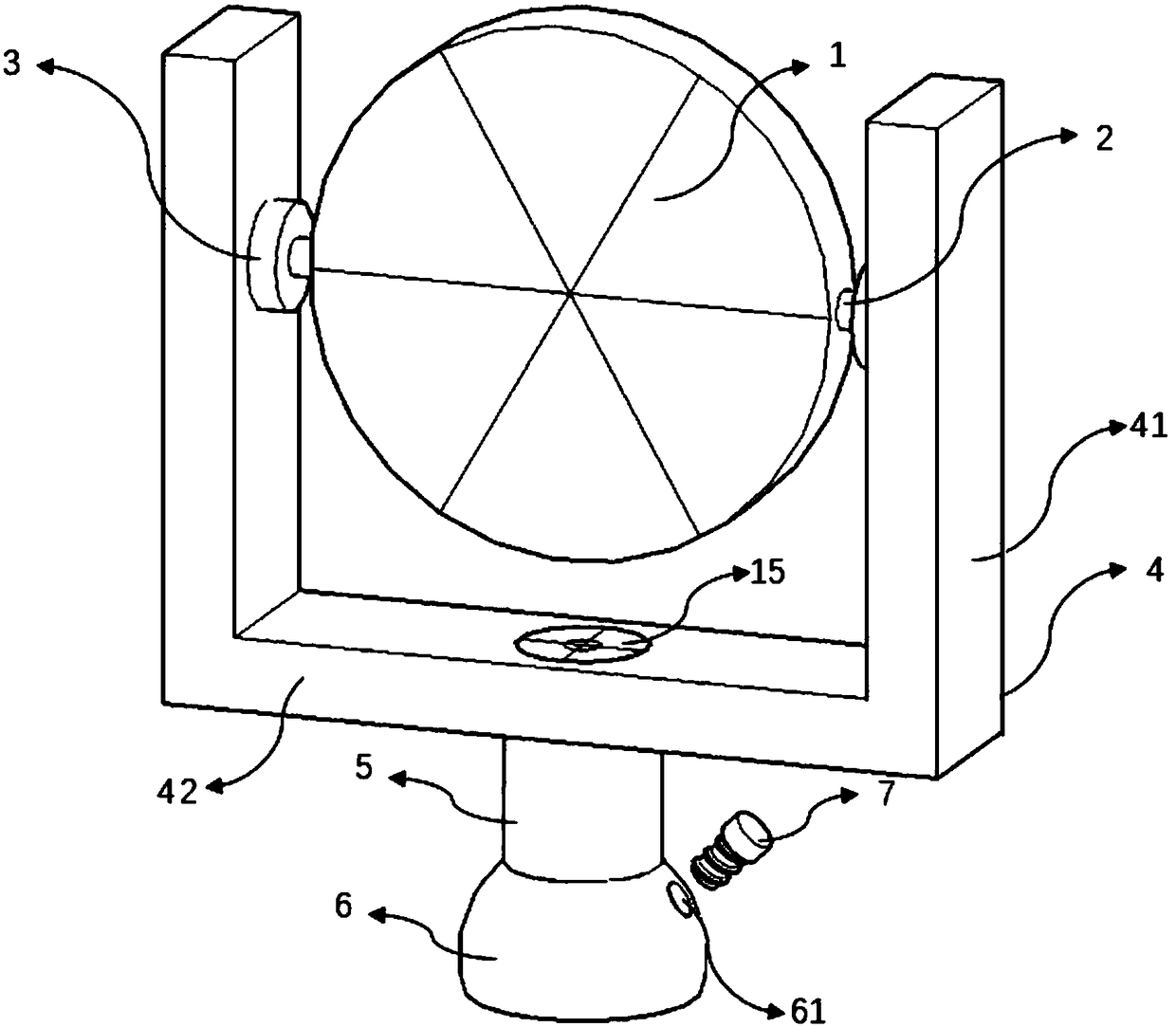

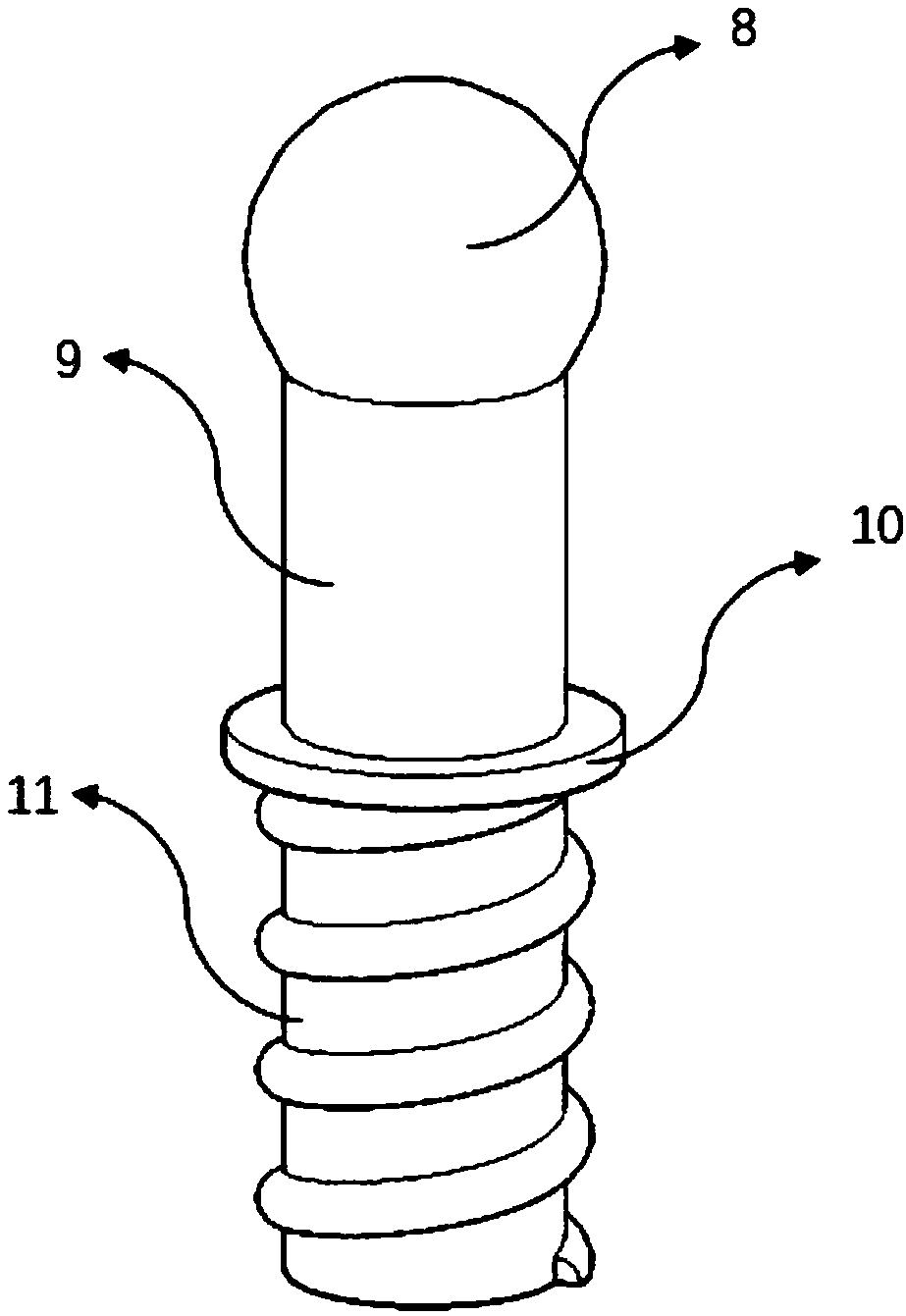

[0030] Such as figure 1 As shown, the present embodiment provides a total station prism, including an upper prism assembly, a middle connection assembly and a lower embedded assembly, the upper prism assembly includes a prism 1 and a prism bracket 4, and the prism 1 is rotatably connected to the top of the prism bracket 4 , the prism support level 15 is installed on the prism support 4, the bottom of the prism support 4 is provided with the first fixed column 5; The top of the two fixed columns 9 is connected, and the universal connector is used to realize the universal rotation adjustment and fixing of the upper prism assembly above the middle connection assembly. The bottom of the second fixed column 9 is provided with a screw rod 11; The sleeve nut 13 that cooperates with the screw rod 11 is connected, the top of the sleeve nut 13 is covered with a steel plate 12 , and the bottom of the sleeve nut 13 is provided with a pre-embedded steel bar 14 .

[0031] In this specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com