Electric probe for shock wave measurement and making method thereof

A manufacturing method and technology of electric probes, which are applied in the direction of measuring electricity, measuring electric variables, and parts of electrical measuring instruments, etc., can solve the problems of limited use, low use rate, high processing technology requirements, etc., and achieve good shock wave responsiveness , reduced manufacturing cost, and wide response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

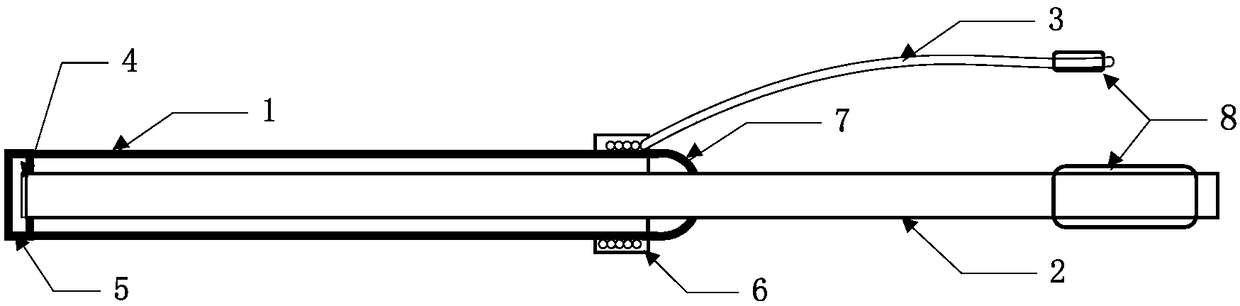

[0051] The electrical probe used for shock wave measurement provided by the present invention, its preparation method comprises the following steps:

[0052] (1) Polish the incisions of the metal capillary 1 and the enamelled metal wire 2 smooth with fine sandpaper, and clean them;

[0053] (2) One end of the metal lead wire 3 is stripped of the insulating layer and dipped in tin, and one end of the enamelled wire 2 is scraped and dipped in tin to form a tinned layer 8, which is convenient for welding during use;

[0054] (3) Prepare polyurethane paint, diluent, and curing agent according to 1:X:0.5 (X=0.3-0.8) at room temperature. Put it into an electric drying oven, and form an insulating coating 4 after curing;

[0055] (4) Put one end of the enamelled metal wire 2 coated with the insulating coating 4 into the metal capillary 1, the top of the enamelled metal wire 2 is 0.1-0.2 mm away from the top of the metal capillary, and a pin or sewing needle with a sharpened tip can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com