A combined casting and forging forming process for deformed aluminum alloy workpieces

A deformed aluminum alloy and forming process technology, which is applied in the field of aluminum alloy workpiece manufacturing, can solve the problems of high processing cost and low processing efficiency of deformed aluminum alloy, and achieve the effects of improving manufacturing efficiency, eliminating mechanical processing links, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A combined casting and forging forming process for a deformed aluminum alloy workpiece, comprising the following steps:

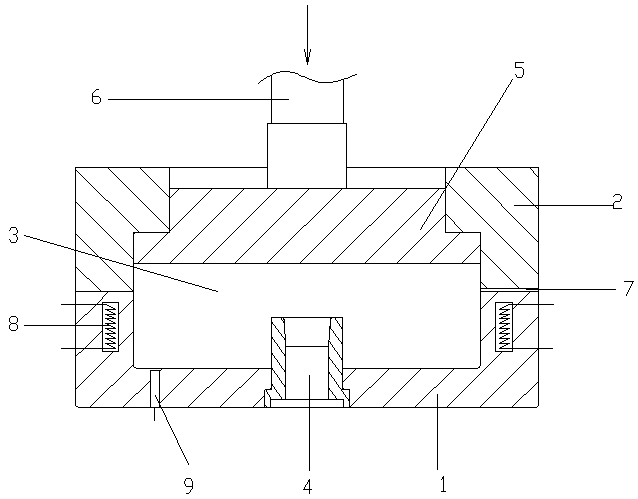

[0020] a. Clamp the mold. After the mold is closed, perform preheating treatment. The preheating temperature is 220°C-250°C, the preheating time is 30s-50s, and the liquid deformed aluminum alloy above 750°C is injected into the mold cavity; figure 1 As shown, the mold includes a lower mold 1 and an upper mold 2, and the mold cavity 3 is formed after the upper mold and the lower mold are closed. The outer end of the mold cavity adjustment slider is connected to the press 6, a number of overflow holes 7 are provided at the connection between the upper mold and the lower mold, and a heating mechanism 8 and a temperature sensor 9 are installed in the mold. The temperature sensor is used to detect the inner wall of the mold cavity. the temperature at;

[0021] b. The deformed aluminum alloy in the mold cavity is naturally cooled for the fi...

Embodiment 2

[0022] Embodiment 2: Add a grain refiner with a mass ratio of 0.3%-0.5% to the liquid deformed aluminum alloy in the melting furnace, the grain refiner is AlTi, and an ultrasonic generator is arranged outside the mold, and the whole mold is placed In the ultrasonic wave; the liquid deformed aluminum alloy containing the grain refiner is injected into the mold cavity, and the rest of the steps are the same as in Example 1.

[0023] The complete deformed aluminum alloy workpiece directly manufactured by the process of combining casting and forging in the present invention saves the semi-finished product link and the subsequent mechanical processing link, which greatly improves the manufacturing efficiency of the deformed aluminum alloy product and reduces the manufacturing cost. , the mechanical properties of the deformed aluminum alloy workpiece produced by this process can reach the performance of the deformed aluminum alloy workpiece produced by the traditional process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com