Micro LED display panel manufacturing method and Micro LED display panel

A technology of a display panel and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electric solid-state devices, etc., can solve the problem that the upper pixel electrode and the MicroLED upper electrode cannot be properly attached, and the upper pixel electrode and the MicroLED upper electrode cannot be realized. Electrical connection and other issues, to avoid poor connection and improve the effect of the group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0029] see Figure 4 , the present invention provides a method for manufacturing a Micro LED display panel, comprising the following steps:

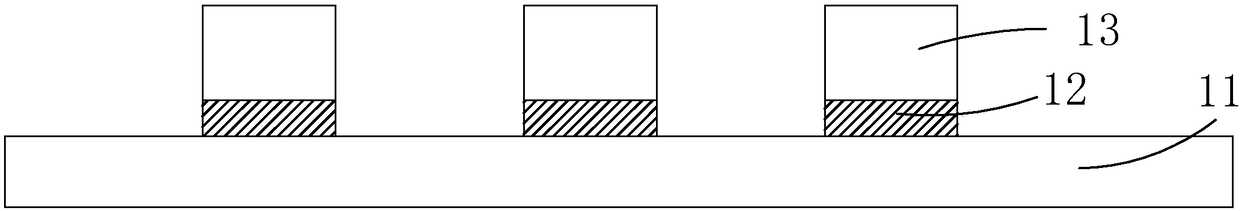

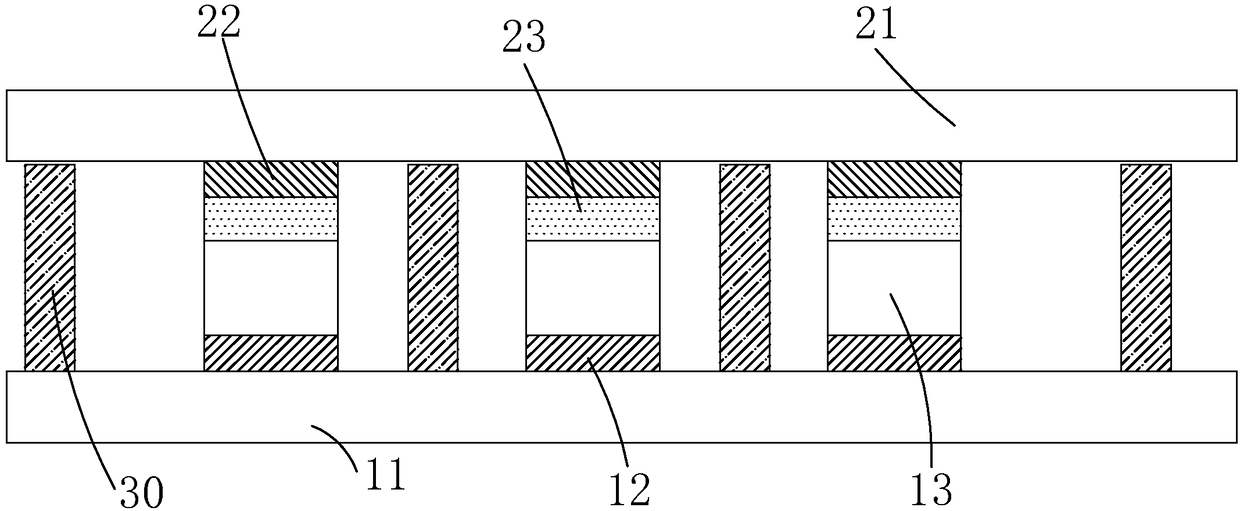

[0030] Step S1, please refer to figure 1 , providing a driving substrate 11, forming a plurality of lower pixel electrodes 12 arranged in an array on the driving substrate 11, and forming a vertical Micro LED 13 on each lower pixel electrode 12, and each lower pixel electrode 12 is connected with the Corresponding to the electrical connection of the lower electrode of Micro LED13;

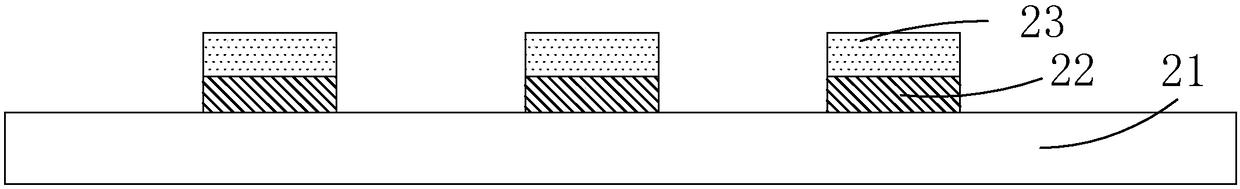

[0031] Step S2, please refer to figure 2 , providing a packaging substrate 21, forming a plurality of upper pixel electrodes 22 arranged in an array on the packaging substrate 21, and forming an elastic conductive layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com