Vibrating type thickener

A thickener and vibration type technology, which is applied in the field of concentration treatment process equipment, can solve the problems of the use of secondary concentration equipment, the inability of the thickener, and the low concentration efficiency, and achieves the advantages of increasing the chance of collision and agglomeration, having a simple structure and accelerating the settling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

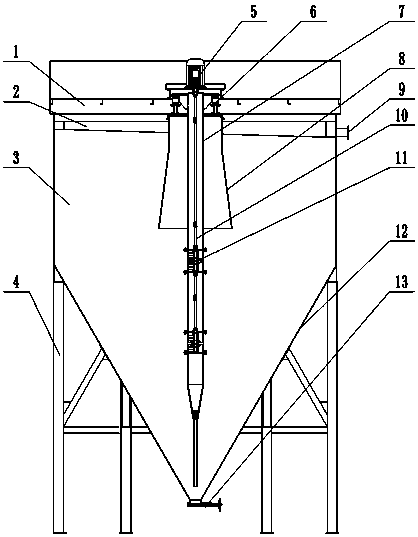

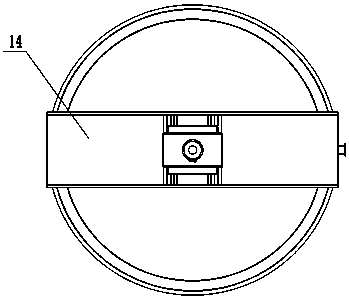

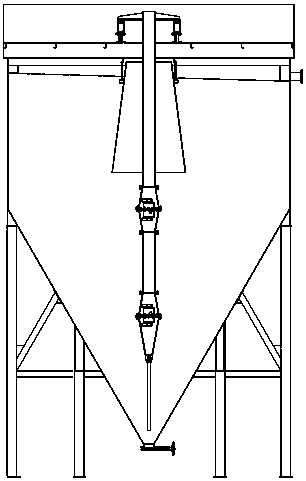

[0019] see figure 1 , figure 2 , the present invention is a vibrating thickener, which has a thickener support 4, on which a pool body is mounted, and the pool body is composed of an upper column 3 and a lower cone 12 connected to each other, and an unloader is provided at the lower end of the lower cone. Feed port 13, supernatant overflow tank 2 and overflow tank outlet 9 are installed around the upper part of the pool body, beam 1 and walkway 14 are arranged at the midline above the pool body, and feeding channel 8 is hoisted below the middle part of the beam. The inclination angle between the conical surface of the cone and the horizontal plane is 50°~70°; the motor 5 and the long cylindrical vibrating rod are installed in the middle of the beam, the motor is fixed on the beam through the machine base, and the long cylindrical vibrating rod is passed through the vibration damping spring 6 is suspended on the beam, and the long cylindrical vibrating rod is composed of a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com