Powder uniform mixing equipment for electric brush production and mixing method

A powder and mixing technology, which is applied in the direction of mixing methods, mixers, solid-solid mixing, etc., can solve the problems of complex mixing and low mixing efficiency, and achieve the effect of improving mixing efficiency and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

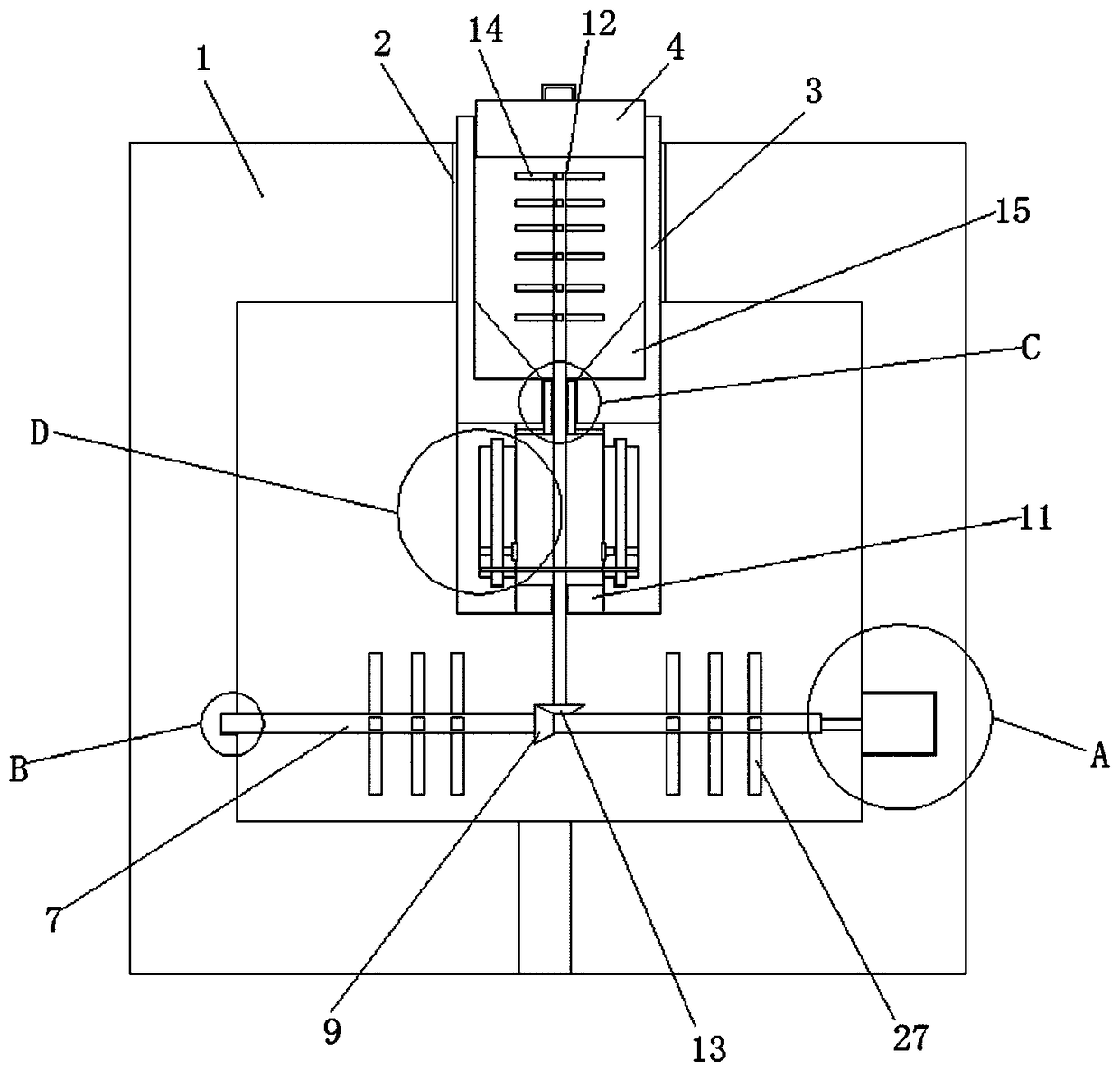

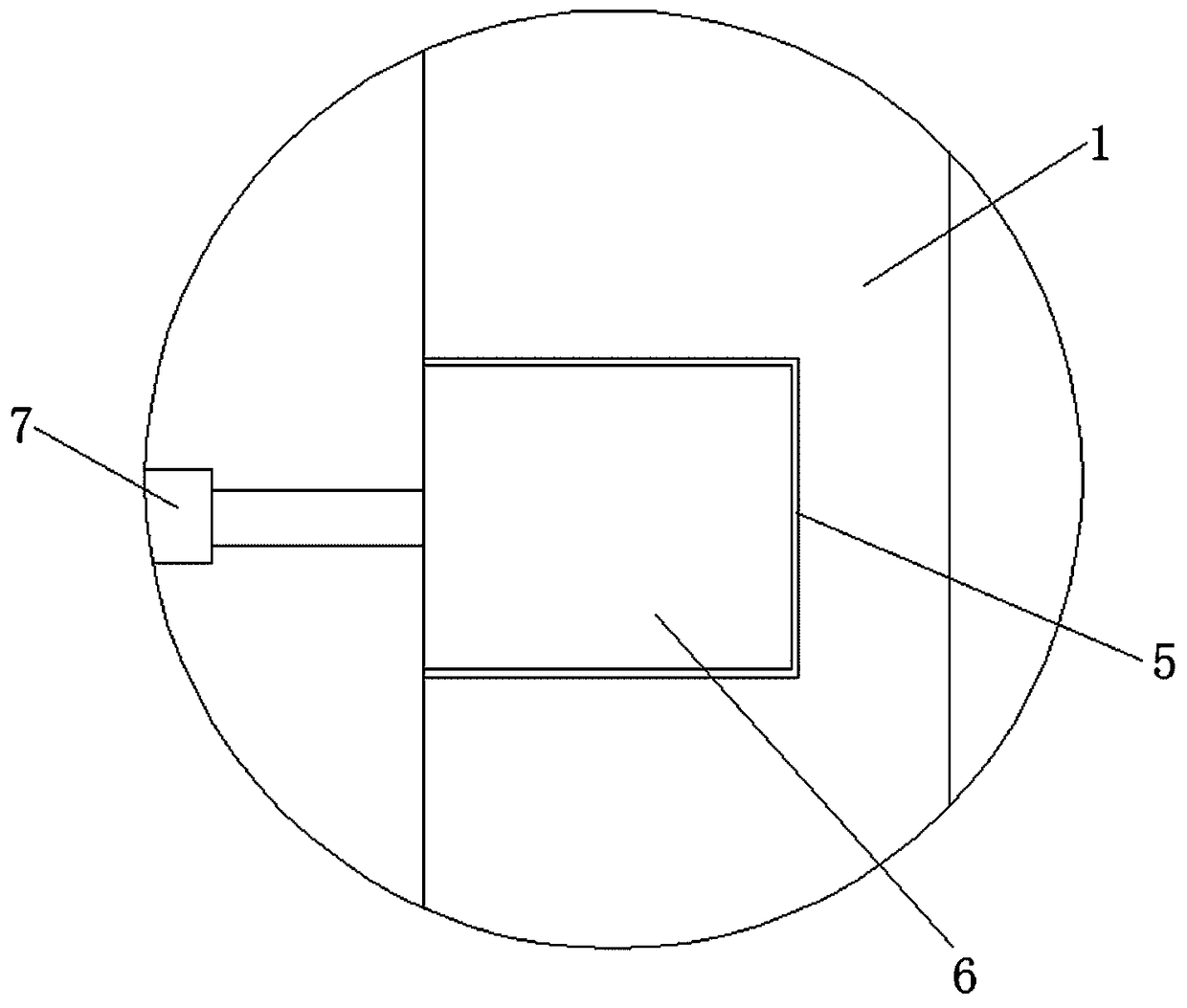

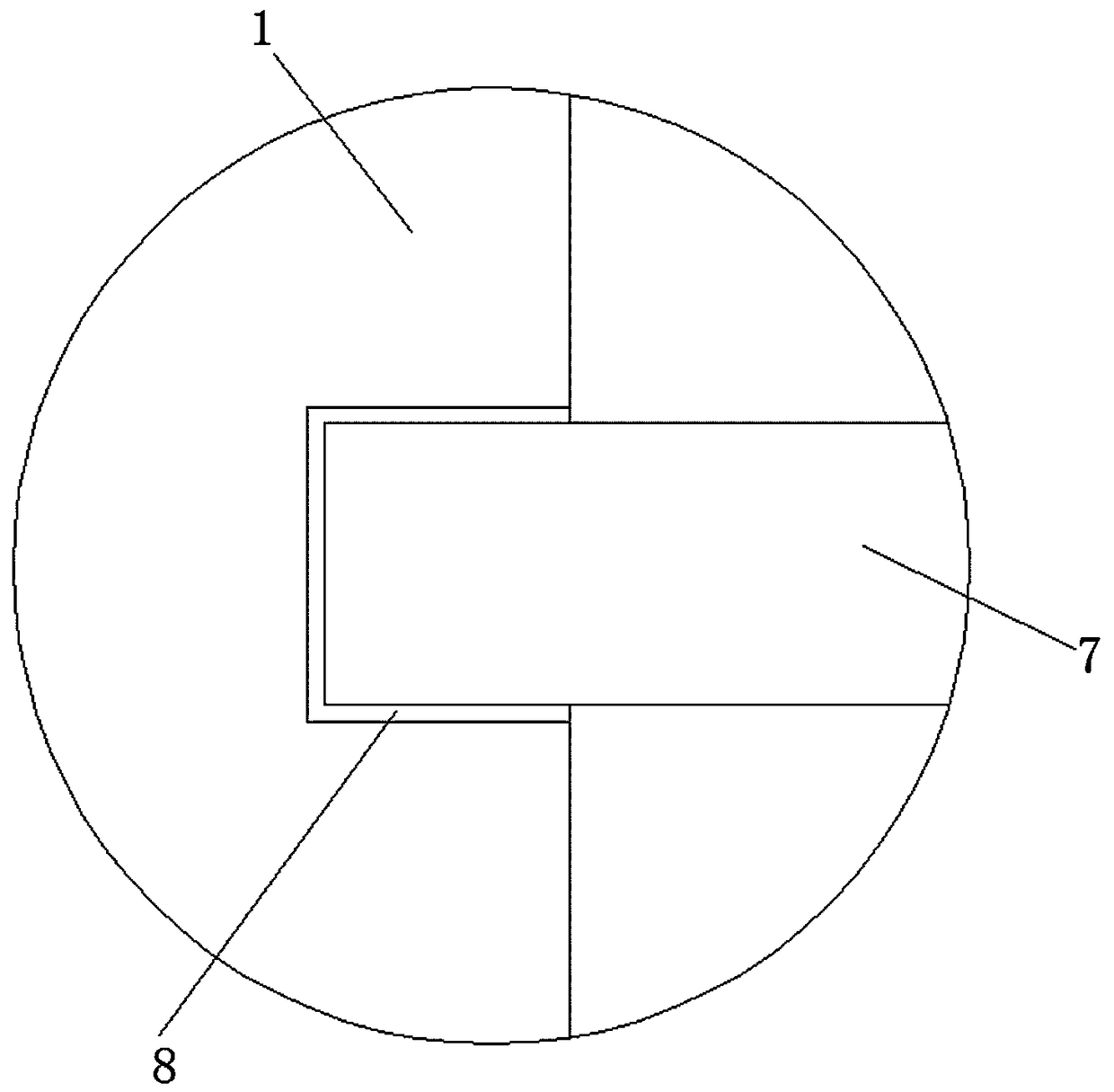

[0030] refer to Figure 1-5, a kind of powder mixing equipment for brush production is proposed in the present embodiment, comprising a processing box 1, the top of the processing box 1 is provided with an installation hole 2, and a placement box 3 with an opening on the top is installed in the installation hole 2, and the placement box The inner wall of 3 is provided with placement cover 4, and on the both sides inner wall of processing case 1, is respectively provided with installation groove 5 and first rotation groove 8, and stepper motor 6 is installed in the installation groove 5, and on the output shaft of stepper motor 6 A rotating shaft 7 is welded, and the end of the rotating shaft 7 away from the stepping motor 6 extends into the first rotating groove 8. The outer fixed sleeve of the rotating shaft 7 is provided with a first bevel gear 9, and the bottom of the placing box 3 extends into the processing box 1. Both sides of the bottom of the placement box 3 are welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com