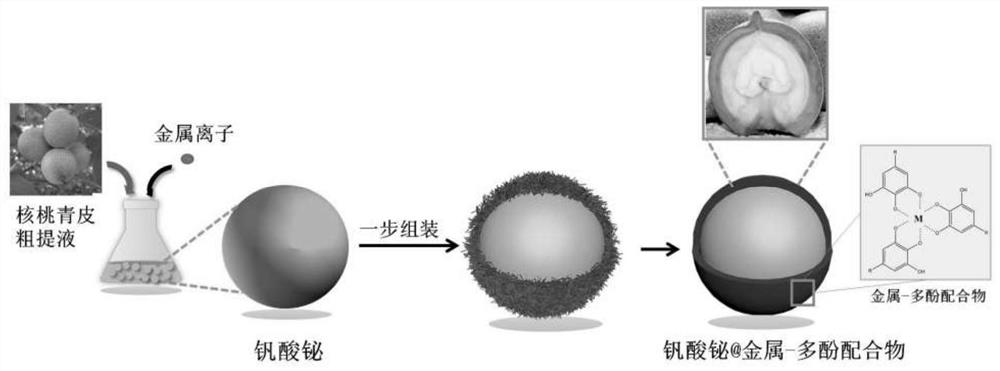

A preparation method of bismuth vanadate@metal-polyphenol complex core-shell structure composite material using crude walnut green bark extract

A technology of walnut green husk and core-shell structure, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, water pollutants, etc., to achieve low energy consumption, simple operation, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

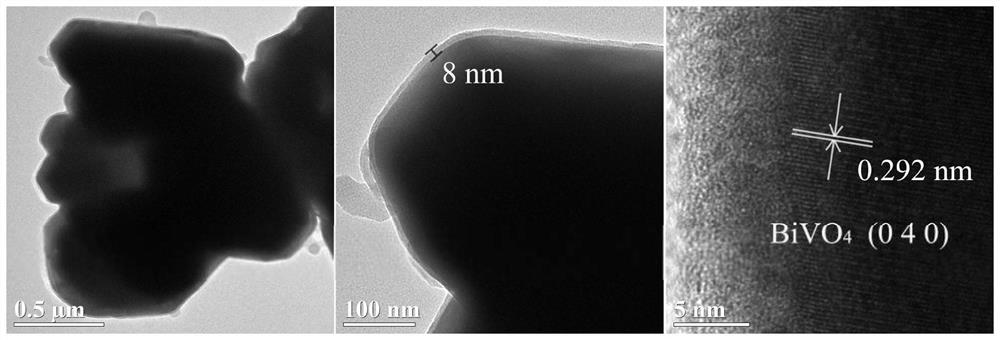

[0035] BiVO 4 The sample preparation steps are as follows:

[0036] Step A: get the bismuth salt of 0.02mol and be dissolved in the concentrated nitric acid of 20mL to obtain homogeneous solution, stir 2 hours; Described bismuth salt is Bi(NO 3 ) 3 ·5H 2 O;

[0037] Step B: 0.02mol of vanadium-containing compound is dissolved in 20mL of 6M NaOH aqueous solution, and the vanadium-containing compound is NH 4 VO 3 ;

[0038] Step C: Add the solution obtained in Step B to the solution obtained in Step A, then add 0.1 g of cetyltrimethylammonium bromide (CTAB) to the obtained solution, stir for 2 hours, then slowly add 30 mL of 6M NaOH aqueous solution , to obtain a homogeneous suspension, stirred for 2 hours;

[0039] Step D: Add the solution obtained in step 3 into a 100mL stainless steel reaction kettle lined with polytetrafluoroethylene, keep it at 180°C for 48 hours, centrifuge the obtained product with deionized water several times, and then dry it at 60°C for 8 hours....

Embodiment 2

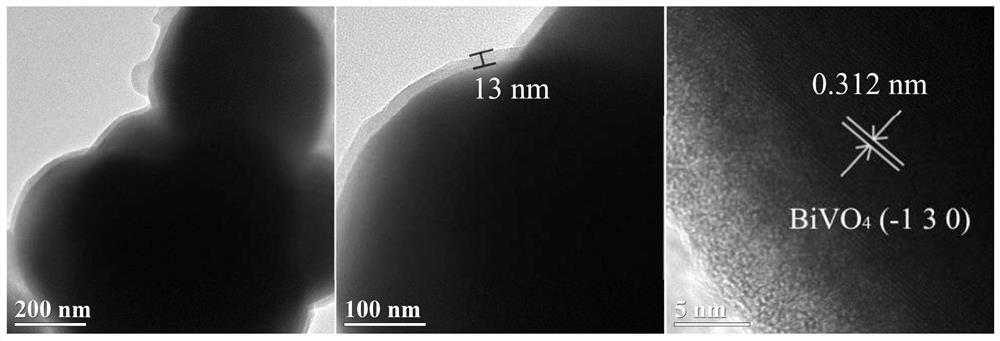

[0047] BiVO 4 The sample preparation steps are as follows:

[0048] Step A: get the bismuth salt of 0.02mol and be dissolved in the concentrated nitric acid of 20mL to obtain homogeneous solution, stir 2 hours; Described bismuth salt is Bi(NO 3 ) 3 ·5H 2 o 3 ;

[0049] Step B: 0.02mol of vanadium-containing compound is dissolved in 20mL of 6M NaOH aqueous solution, and the vanadium-containing compound is NH 4 VO 3 ;

[0050] Step C: Add the solution obtained in step B to the solution obtained in step A, then add 0.2 g cetyltrimethylammonium bromide (CTAB) to the obtained solution, stir for 2 hours, then slowly add 30 mL of 6M NaOH aqueous solution , to obtain a homogeneous suspension, stirred for 2 hours;

[0051] Step D: Add the solution obtained in step 3 into a 100mL stainless steel reaction kettle lined with polytetrafluoroethylene, keep it at 180°C for 48 hours, centrifuge the obtained product with deionized water several times, and then dry it at 60°C for 8 hours...

Embodiment 3

[0059] BiVO 4 The sample preparation steps are as follows:

[0060] Step A: Dissolve 0.02mol of bismuth salt in 20mL of concentrated nitric acid to obtain a uniform solution, and stir for 2 hours; the bismuth salt is BiCl 3 ;

[0061] Step B: 0.02mol of vanadium-containing compound is dissolved in 20mL of 6M NaOH aqueous solution, and the vanadium-containing compound is Na 3 VO 4 ;

[0062] Step C: Add the solution obtained in Step B to the solution obtained in Step A, then add 0.3 g of cetyltrimethylammonium bromide (CTAB) to the obtained solution, stir for 2 hours, then slowly add 30 mL of 6M NaOH aqueous solution , to obtain a homogeneous suspension, stirred for 2 hours;

[0063] Step D: Add the solution obtained in step 3 into a 100mL stainless steel reaction kettle lined with polytetrafluoroethylene, keep it at 180°C for 48 hours, centrifuge the obtained product with deionized water several times, and then dry it at 60°C for 8 hours. Get BiVO 4 sample. The purity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com