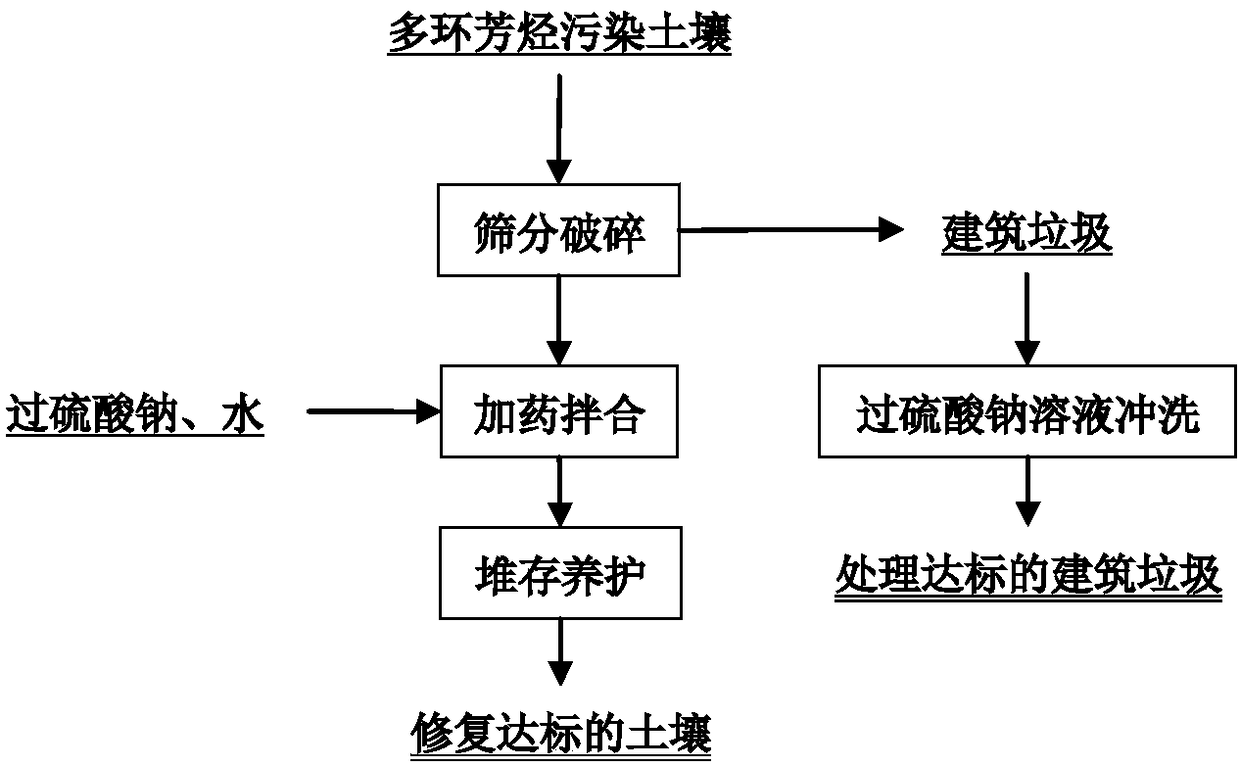

Chemical oxidation repair method of polycyclic aromatic hydrocarbon (PAH) contaminated soil

A technology of polluted soil and chemical oxidation, which is applied in the field of soil remediation, can solve the problems of complex chemical pretreatment process and difficult mud treatment, and achieve the effects of simple chemical types, easy stacking and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 500 tons of PAH-contaminated soil, use screening equipment to screen out construction waste with a particle size greater than 50 mm, and send the screened contaminated soil to crushing equipment for crushing to obtain fine-grained contaminated soil with an average particle size of 20 mm. The construction waste obtained by sieving is rinsed with 0.2 wt.% sodium persulfate solution to obtain clean construction waste. Add 2.5 tons of sodium persulfate and an appropriate amount of water to the fine-grained polluted soil, mix the polluted soil 3 times with an ALLU bucket to obtain a soil with a moisture content of 30%; place the mixed soil after the dosing Store and maintain in a cool place for 6 days to obtain repaired and up-to-standard soil.

Embodiment 2

[0032] Take 500 tons of PAH-contaminated soil, use screening equipment to screen out construction waste with a particle size greater than 50 mm, and send the screened contaminated soil to crushing equipment for crushing to obtain fine-grained contaminated soil with an average particle size of 15 mm. The construction waste obtained by sieving is washed with a sodium persulfate solution with a concentration of 2 wt.%, to obtain clean construction waste. Add 10 tons of sodium persulfate and an appropriate amount of water to the fine-grained polluted soil, mix the polluted soil 4 times with an ALLU bucket to obtain a soil with a moisture content of 30%; place the mixed soil after the dosing Store and maintain in a cool place for 8 days to obtain repaired and up-to-standard soil.

Embodiment 3

[0034] Take 500 tons of PAH-contaminated soil, use screening equipment to screen out construction waste with a particle size greater than 50 mm, and send the screened contaminated soil to crushing equipment for crushing to obtain fine-grained contaminated soil with an average particle size of 5 mm. The construction waste obtained by sieving is washed with a sodium persulfate solution with a concentration of 1 wt.%, to obtain clean construction waste. Add 5 tons of sodium persulfate and an appropriate amount of water to the fine-grained polluted soil, mix the polluted soil 3 times with an ALLU bucket to obtain a soil with a moisture content of 35%; place the mixed soil after the dosing Store and maintain in a cool place for 7 days to obtain repaired and up-to-standard soil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com