Smoke and dust suction device and laser production equipment

A vacuum device, laser technology, applied in the direction of laser welding equipment, printing equipment, welding equipment, etc., can solve the problems of not being compatible with PCB production lines, poor smoke and dust suction effect, low efficiency, etc., to avoid the influence of smoke and dust, Good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

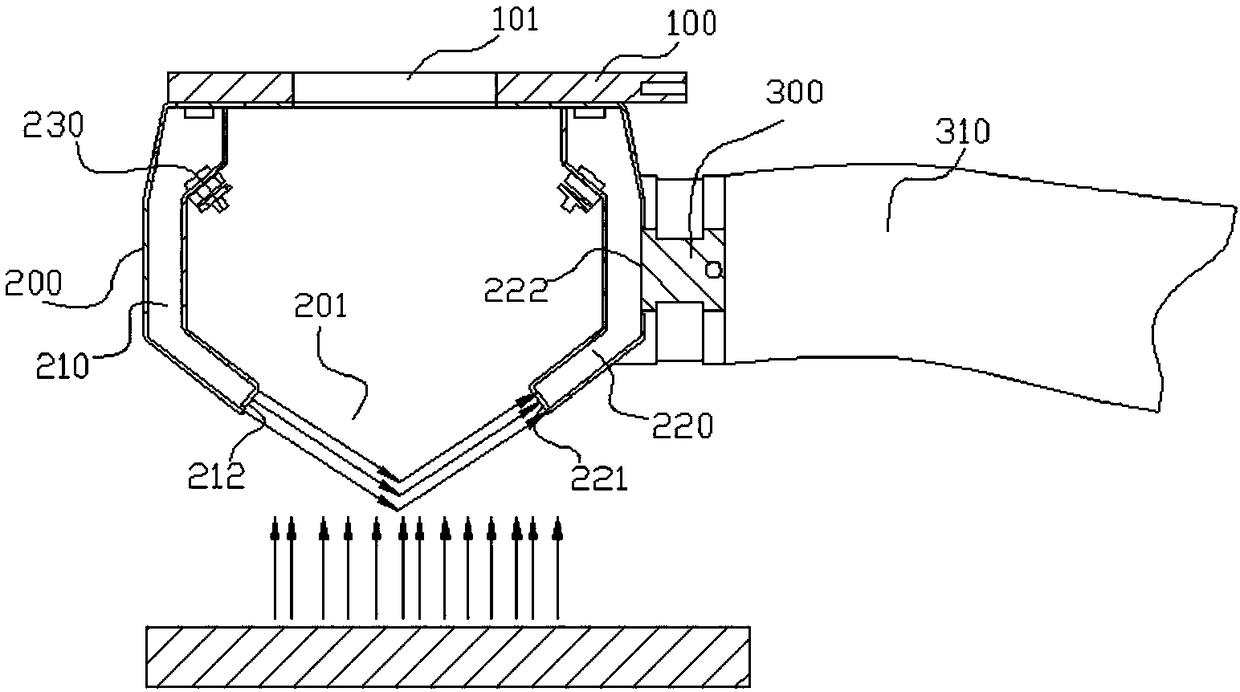

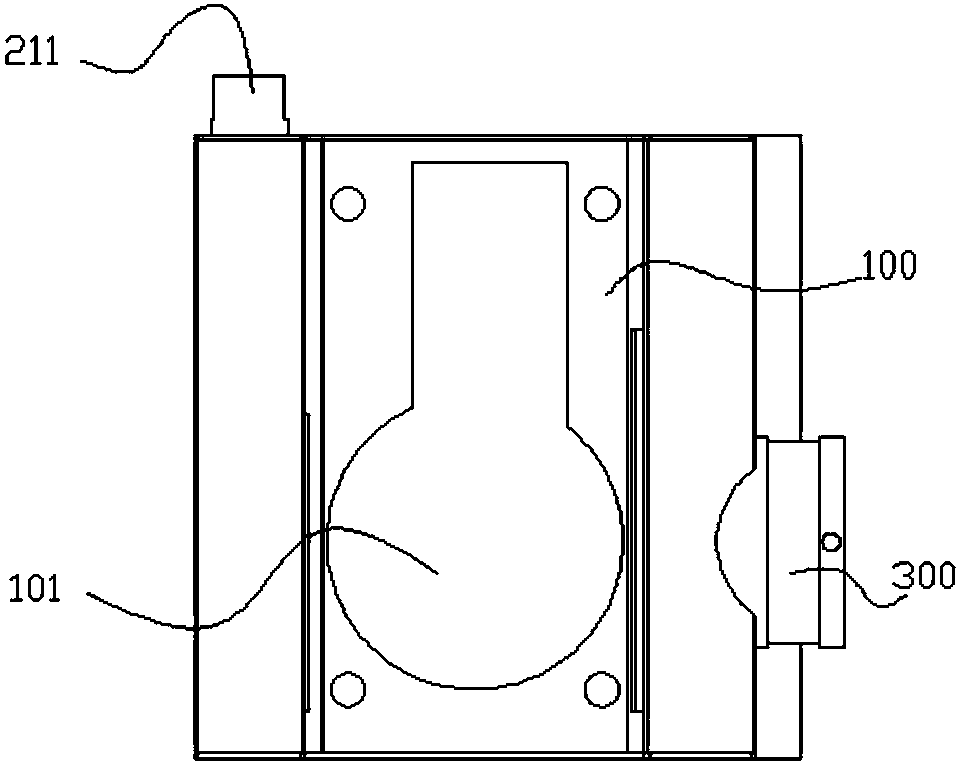

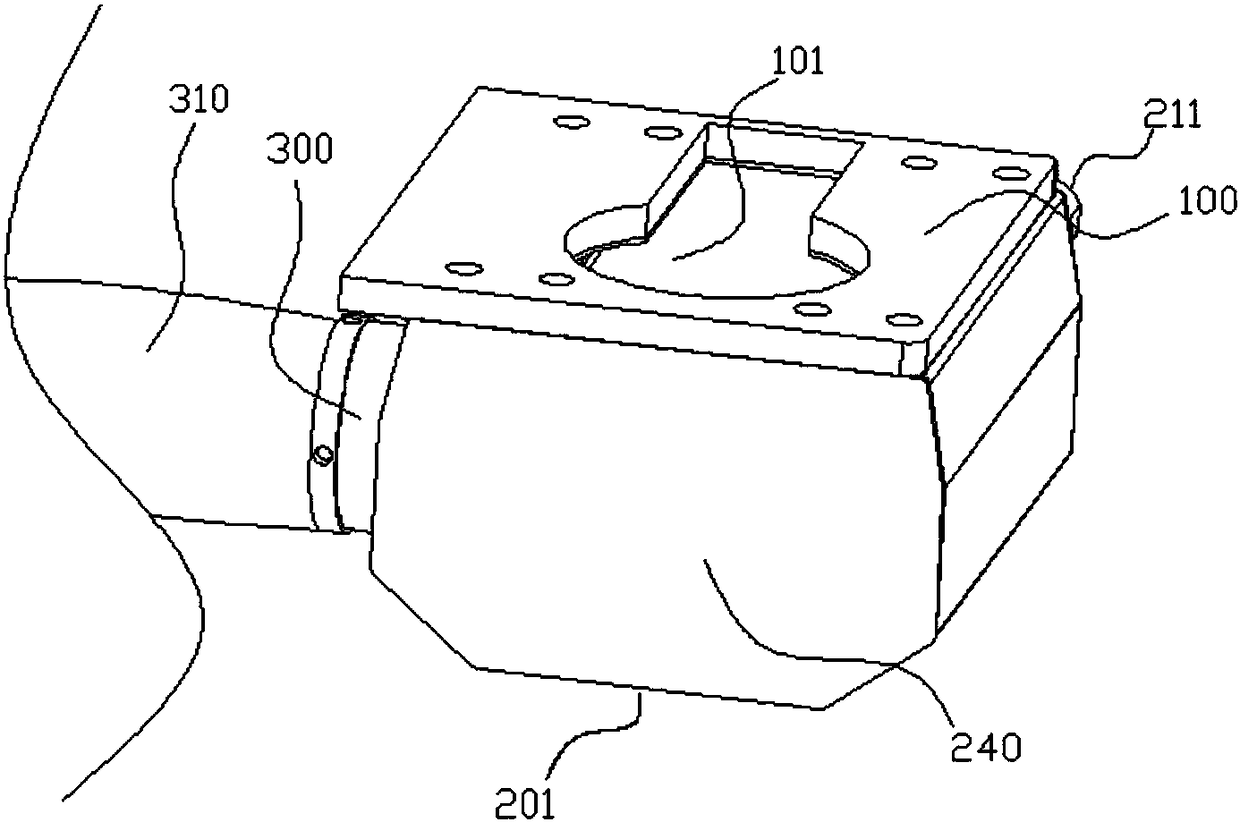

[0026] see Figure 1~3 The smoke and dust suction device of the present invention includes a fume hood main body 200 and a fixing plate 100, the fume hood main body 200 is installed under the fixing plate 100, and the light outlet 101 that allows the laser to pass through is provided on the fixing plate 100, and the fume hood The main body 200 is a cover structure surrounded by surroundings. The interior of the smoke hood main body 200 is a space communicating with the light outlet 101 . The hood structure of the fume hood main body 200 is provided with a blowing channel 210 and a suction channel 220 which are independent of each other, and the blowing channel 210 is provided with an air inlet 211 connected to an external blowing device and a dust blowing port 212 connected thereto. The suction channel 220 is provided with a suction port 222 connected to external suction equipment and a dust suction port 221 connected thereto. The dust blowing port 212 and the dust suction por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com