Particle shape modifying device for concrete or asphalt mixture aggregates

A technology of asphalt mixture and concrete, applied in the direction of screen, grid, solid separation, etc., to achieve the effect of full grain shape, convenient installation and use, reducing damage and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

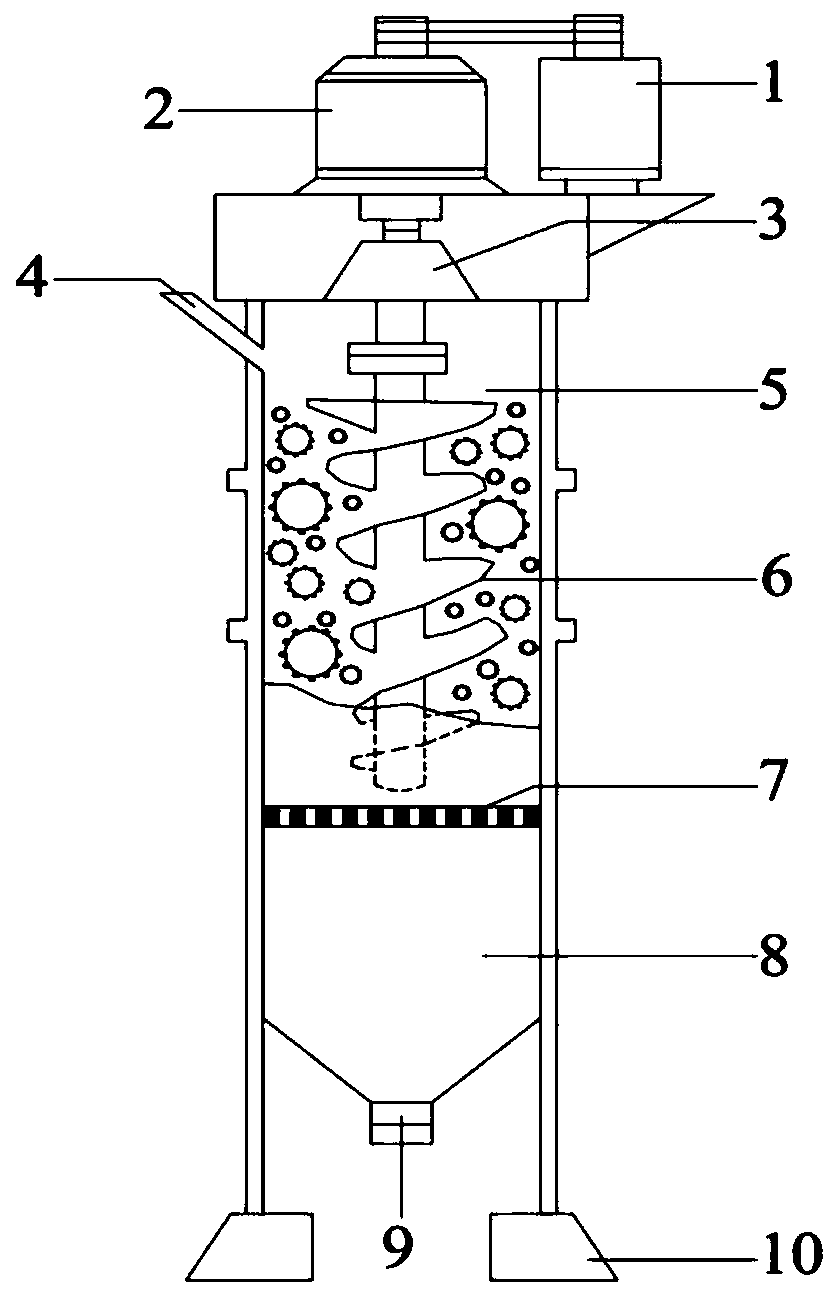

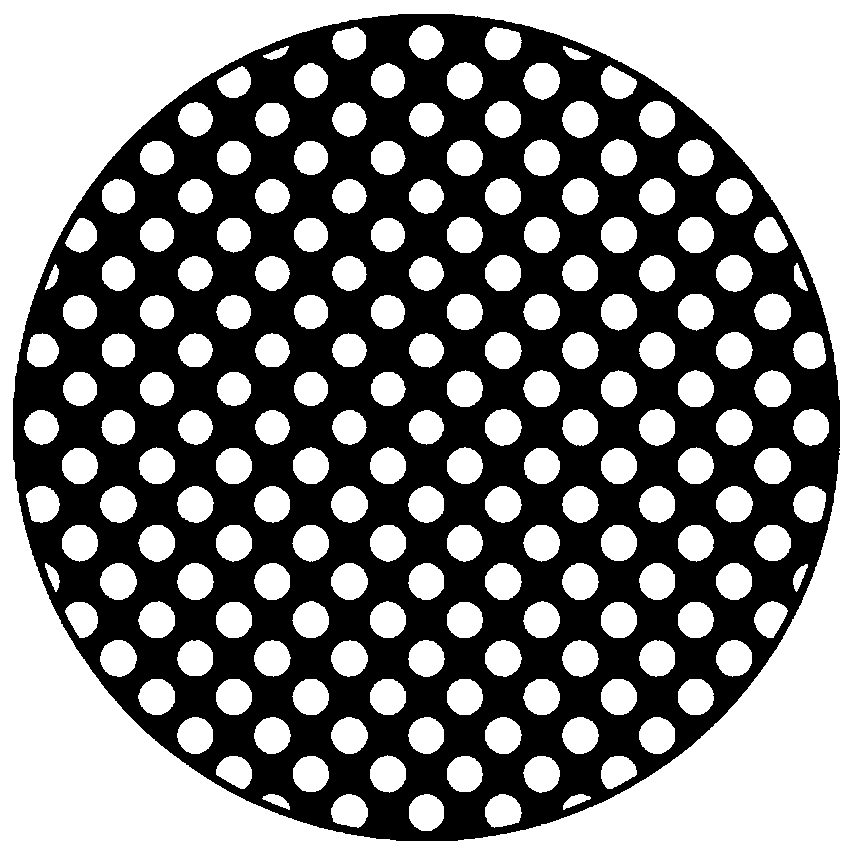

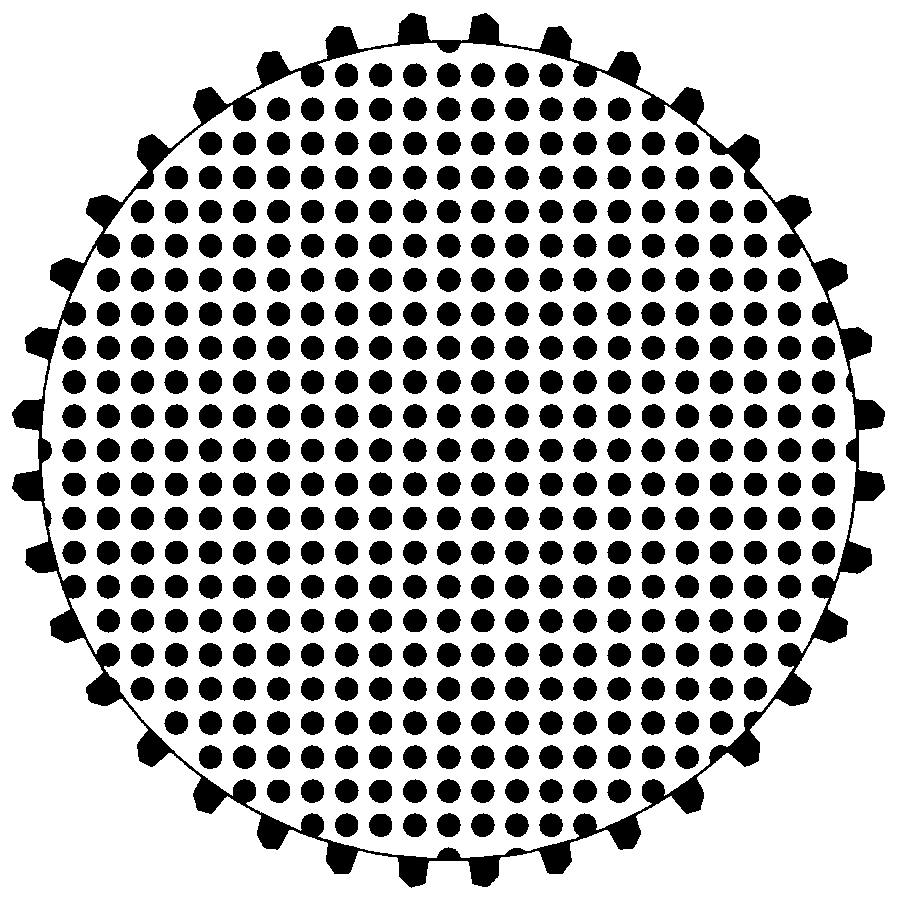

[0030] figure 1 Shown is the concrete or asphalt mixture aggregate particle shape modification device of the technical solution 1 proposed by the present invention, including a silo and an agitator 6 . The silo is a vertically arranged drum-shaped silo, designed as a double silo, and is divided into a particle shape modification silo 5 and a collection silo 8 by a material partition plate 7 . The collection bin 8 is located under the granular modification bin 5 . The agitator 7 is a helical agitator, which is placed vertically in the particle shape modification bin, on the center line of the vertical axis. A plurality of metal grinding balls are arranged in the grain shape modification bin, and a feed inlet 4 is arranged on the side upper part of the grain shape modification bin. The blanking holes (grit holes) are evenly arranged on the surface of the material separating plate 7 . The bottom of the collection bin 8 is in the shape of a funnel, and the bottom of the funnel ...

Embodiment 2

[0041] Basically the same as the embodiment, the difference is: as Figure 4 As shown, the granular modification bin is in the shape of a horizontal barrel, the upper part of the granular modification bin is provided with a feeding port, the lower part of the granular modification bin is open and docked with the collection bin, and the opening is provided with the material partition board. The agitator is arranged transversely on the axis of the grain modification bin. The stirrer can choose a spiral stirrer (such as Figure 4 shown), a non-helical agitator can also be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com