Method for making ultrahigh molecular weight polyethylene board adhere to steel plate surface

A technology of ultra-high molecular weight and polyethylene, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc. Coefficient of large differences and other issues, to achieve high wear resistance and impact resistance, smoothness improvement, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

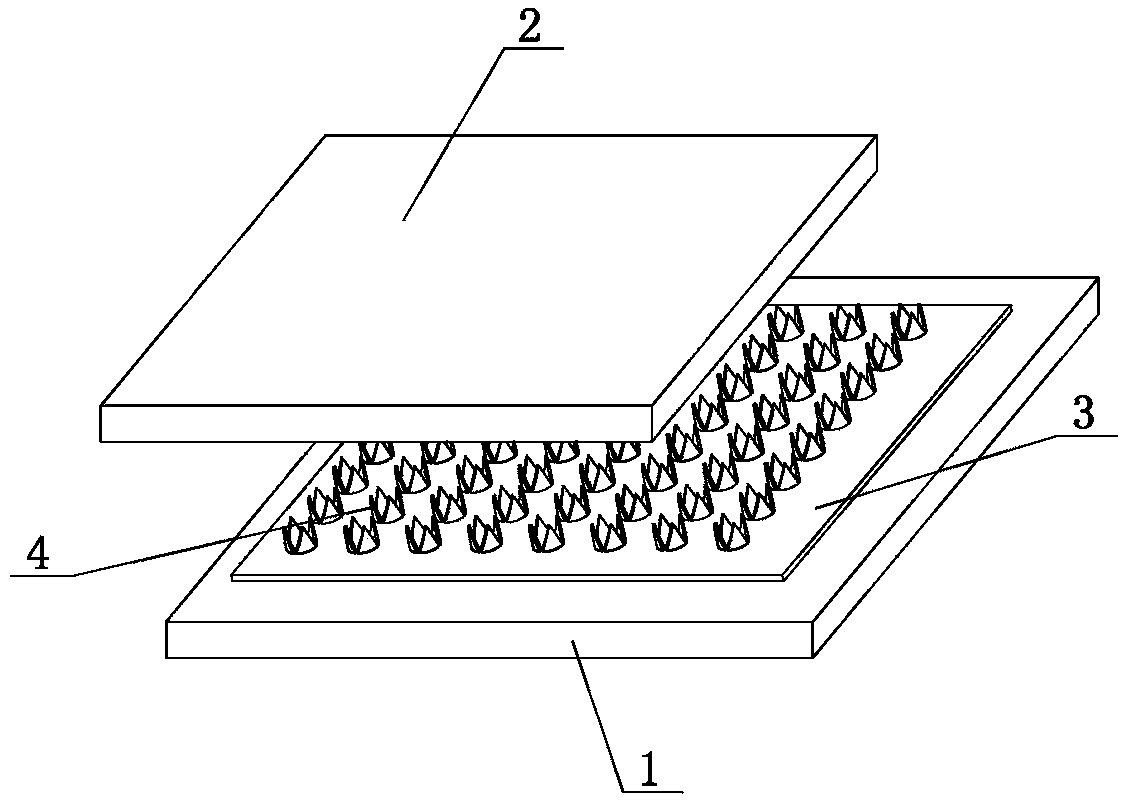

[0018] The present invention will be further described with reference to the accompanying drawings.

[0019] A method for sticking ultra-high molecular weight polyethylene sheets on the surface of steel plates according to the present invention comprises the following steps:

[0020] ①Ultra-high molecular weight polyethylene strip plate is made into a width of 27-35 cm and a thickness of 2-20 mm, and then the above strip plate is cut into square or rectangular blocks for use;

[0021] ② heat-bond a thin layer of plastic film on one surface of the square or rectangular ultra-high molecular weight polyethylene sheet in step ① to form a film-coated sheet;

[0022] 3. Get the tinplate sheet to make a square or rectangular block, which is the same size and shape as the ultra-high molecular weight polyethylene sheet in step 1. The thickness of the tinplate sheet is 0.3-0.8 mm;

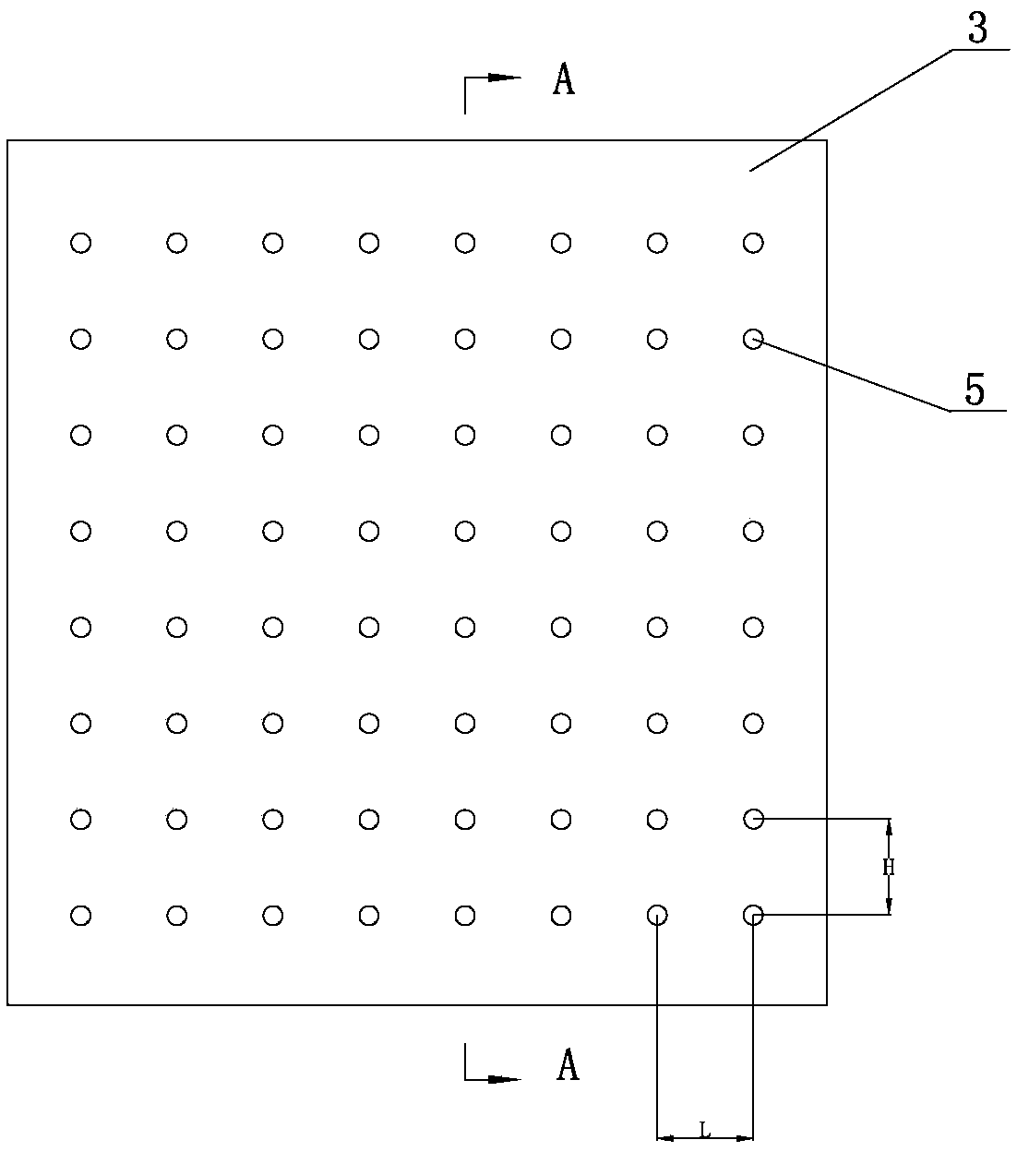

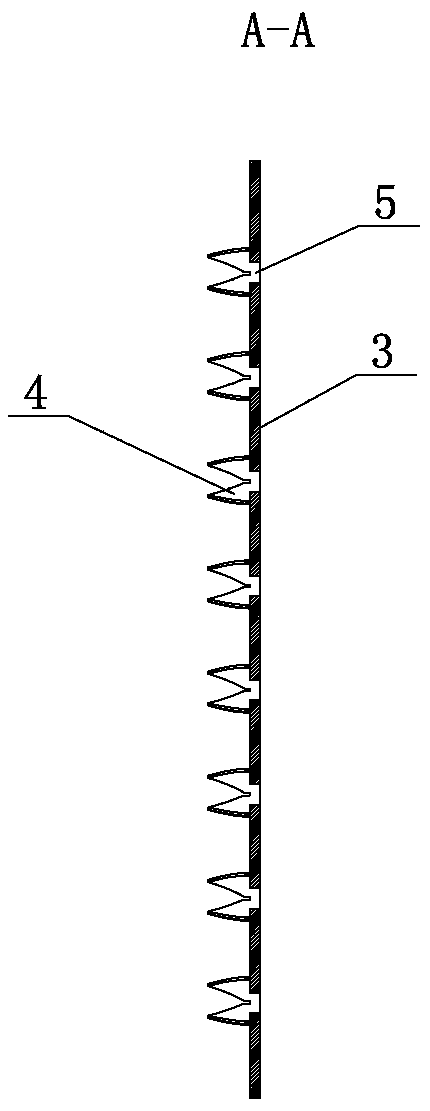

[0023] ④ Punch out several rows of through holes on the tinplate sheet described in step ③ by using a pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com