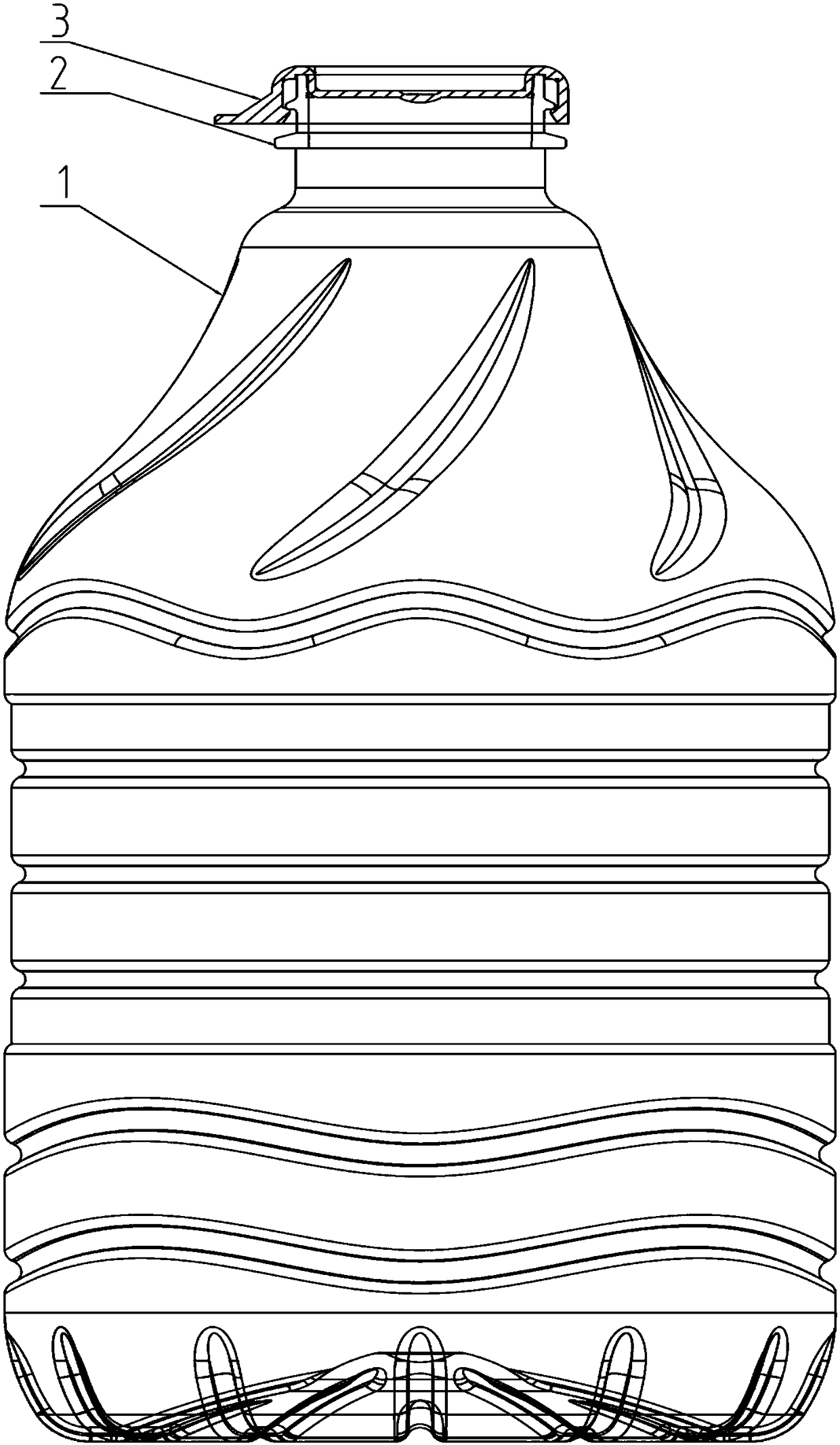

Novel water bottle opening combination with outer double rings and inner tight seal

A technology of inner sealing and inner sealing surface, which is applied in the field of plastic bottles, can solve the problems of affecting material expenditure, weakening of bottle strength, and the need for easy-to-tear film, so as to save space and reduce cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

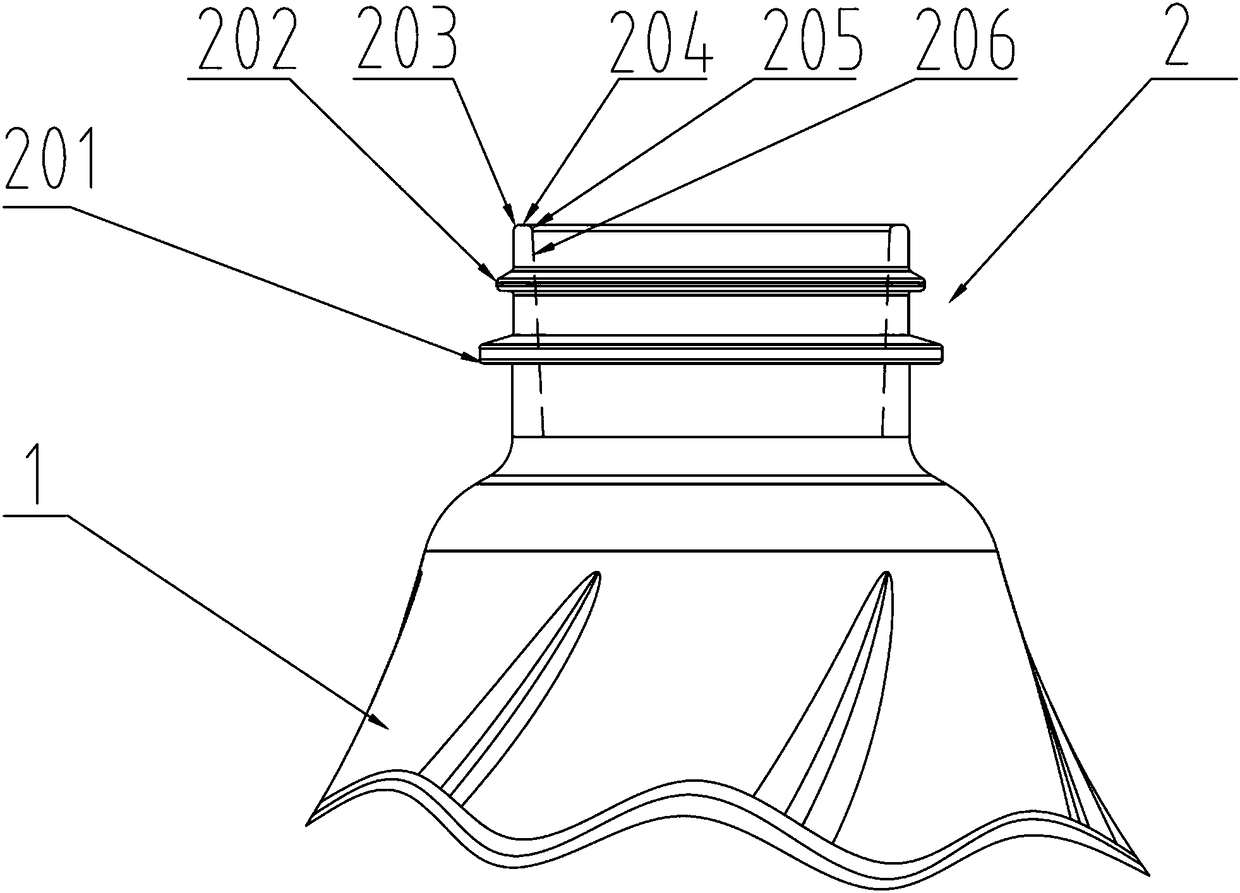

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

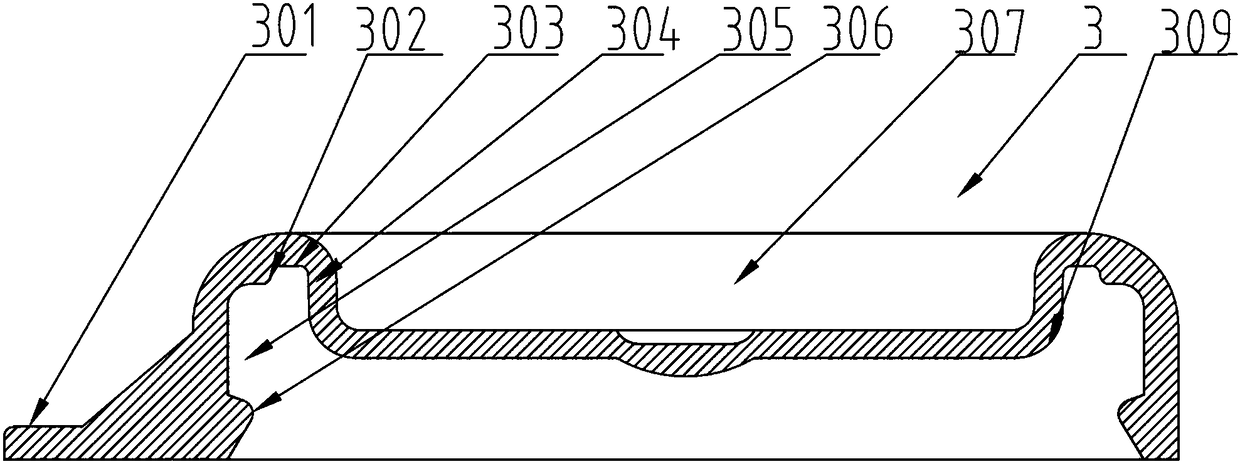

[0027] refer to Figure 1-Figure 3 , said a new type of outer double-ring inner tightly sealed water bottle mouth combination, including bottle mouth 2 and bottle cap 3, said bottle mouth 2 is arranged on the upper end of bottle body 1, and said bottle cap 3 is closed with bottle mouth 2, so The bottle mouth 2 includes a support ring 201 and an outer buckle ring 202. The outer edge of the top of the bottle mouth 2 is a sealed R arc surface 203, the top surface of the bottle mouth 2 is a sealing end surface 204, and the inner edge of the bottle mouth 2 top is a guide arc. Below the surface 205 and the guide arc surface 205 is the inner sealing surface 206, and the shape of the space enclosed by the inner sealing surface 206 is an inverted circular frustum; the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com