Treatment method for municipal sludge

A municipal sludge and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem that the sludge cannot meet the secondary utilization or landfill standards , low dehydration rate, low degree of automation, etc., to achieve the effect of facilitating secondary utilization or landfill, convenient operation, and improving practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

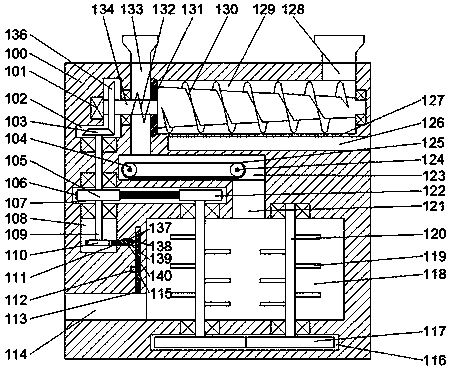

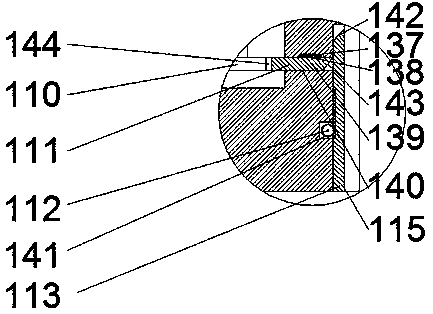

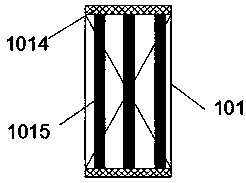

[0024] like Figure 1-Figure 3As shown, a kind of municipal sludge treatment equipment of the present invention includes a fuselage 100 and a blanking channel 133 arranged in the fuselage 100, and the fuselage 100 is provided with a The first transmission cavity 102 on the left side, the right side of the blanking channel 133 is provided with a feeding cavity 129 extending to the right and opening to the left, and the first rotating shaft extending left and right is rotatably provided in the blanking channel 133 134, the first rotating shaft 134 is provided with an extruding plate 131 which can slide left and right, and the left end surface of the extruding disc 131 and the left end wall of the blanking channel 133 are provided with a ring surrounding the first rotating shaft 134 The first spring 132 on the outer surface, the first rotating shaft 134 extends rightward into the feeding chamber 129, the first rotating shaft 134 in the feeding chamber 129 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com