Liquid detergent and preparation method thereof

A technology of laundry detergent and sisal, which is applied in the field of laundry detergent, can solve the problems of reducing the use value of clothes, the three-dimensional effect is not strong, the pattern outline is not clear, etc., and achieve good sterilization and disinfection effects and good color protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

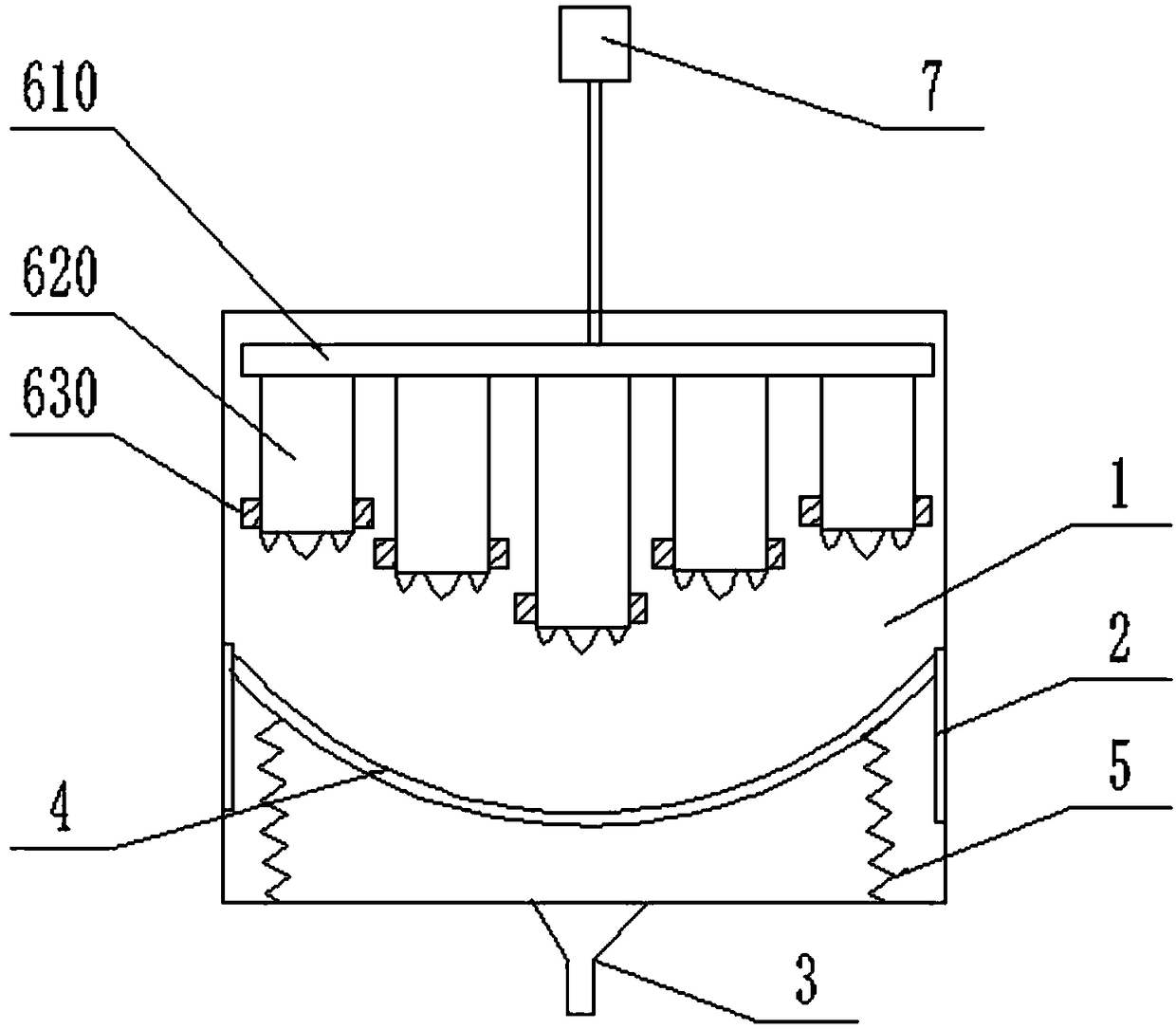

Image

Examples

Embodiment 1

[0027] A preparation method of laundry detergent, comprising the following steps:

[0028] Step 1, take 30 parts of polyoxyethylene alkyl alcohol ether, 28 parts of stearic acid amide, 15 parts of fatty acid glycerides, 20 parts of stearic acid, 15 parts of polyacrylamide and 10 parts of glycerin glycerol by weight and mix and stir , heated in a water bath at 35°C to obtain the first mixture;

[0029] Step 2: Take 25 parts by weight of sodium xylene sulfonate, 25 parts of sodium carboxymethylcellulose, 18 parts of triethanolamine, 16 parts of carboxymethylcellulose and 30 parts of pure water, mix and stir, and slowly add The first mixture was placed in an ultrasonic environment for 20 minutes to obtain a second mixture;

[0030] Step 3, add 16 parts of sodium dodecylbenzenesulfonate, 20 parts of bamboo sisal extract, 15 parts of sodium tripolyphosphate and 38 parts of pure water to the second mixture by weight, mix and stir, ultrasonically vibrate for 30 minutes, and Gradual...

Embodiment 2

[0037] A preparation method of laundry detergent, comprising the following steps:

[0038] Step 1: Take 32 parts of polyoxyethylene alkyl alcohol ether, 29 parts of stearic acid amide, 17 parts of fatty acid glycerides, 25 parts of stearic acid, 16 parts of polyacrylamide and 13 parts of glycerol and mix and stir by weight , heated in a water bath at 35°C to obtain the first mixture;

[0039] Step 2: Take 27 parts by weight of sodium xylene sulfonate, 28 parts of sodium carboxymethyl cellulose, 23 parts of triethanolamine, 22 parts of carboxymethyl cellulose and 32 parts of pure water, mix and stir, and slowly add The first mixture was placed in an ultrasonic environment for 20 minutes to obtain a second mixture;

[0040] Step 3: Add 18 parts of sodium dodecylbenzenesulfonate, 25 parts of bamboo sisal extract, 16 parts of sodium tripolyphosphate and 39 parts of pure water to the second mixture by weight, mix and stir, ultrasonically vibrate for 30 minutes, and Gradually and ...

Embodiment 3

[0047] A preparation method of laundry detergent, comprising the following steps:

[0048] Step 1, take 34 parts of polyoxyethylene alkyl alcohol ethers, 33 parts of stearic acid amide, 20 parts of fatty acid glycerides, 28 parts of stearic acid, 18 parts of polyacrylamide and 16 parts of glycerin glycerol by weight and mix and stir , heated in a water bath at 35°C to obtain the first mixture;

[0049]Step 2: Take 30 parts by weight of sodium xylene sulfonate, 30 parts of sodium carboxymethylcellulose, 27 parts of triethanolamine, 25 parts of carboxymethylcellulose and 35 parts of pure water, mix and stir, and slowly add The first mixture was placed in an ultrasonic environment for 20 minutes to obtain a second mixture;

[0050] Step 3: Add 20 parts of sodium dodecylbenzene sulfonate, 29 parts of bamboo sisal extract, 18 parts of sodium tripolyphosphate and 40 parts of pure water to the second mixture by weight, mix and stir, ultrasonically vibrate for 30 minutes, and Gradua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com