Construction method of full-prefabricated assembly type concrete freight transport suspension type monorail structure

A technology of prefabricated concrete and prefabricated assembly, applied in infrastructure engineering, tracks, roads, etc., can solve the problems of heavy environmental pollution, long construction period, and low construction efficiency, and achieve reliable force transmission performance, good fatigue resistance, and convenient construction The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

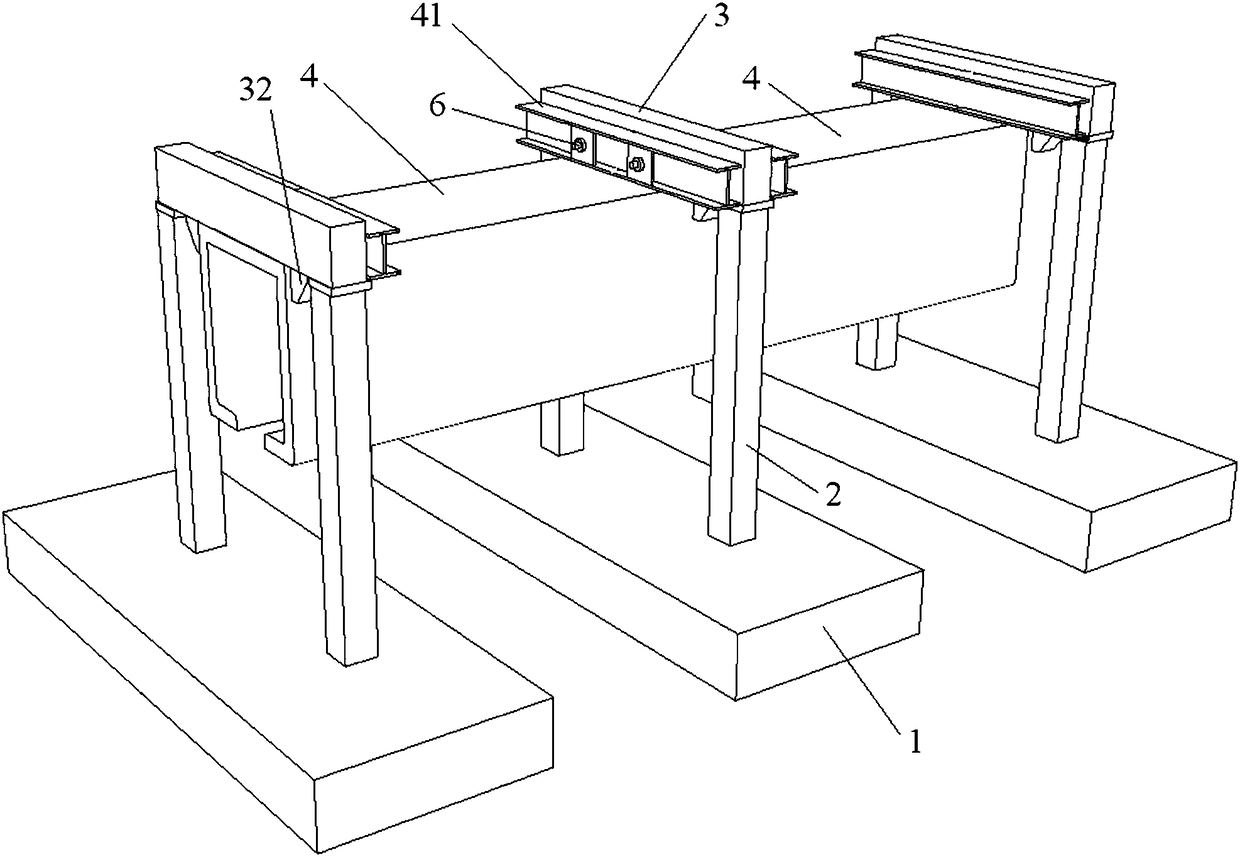

[0053] like Figure 1-Figure 5 As shown, a construction method of a fully prefabricated concrete freight suspension monorail structure comprises the following steps:

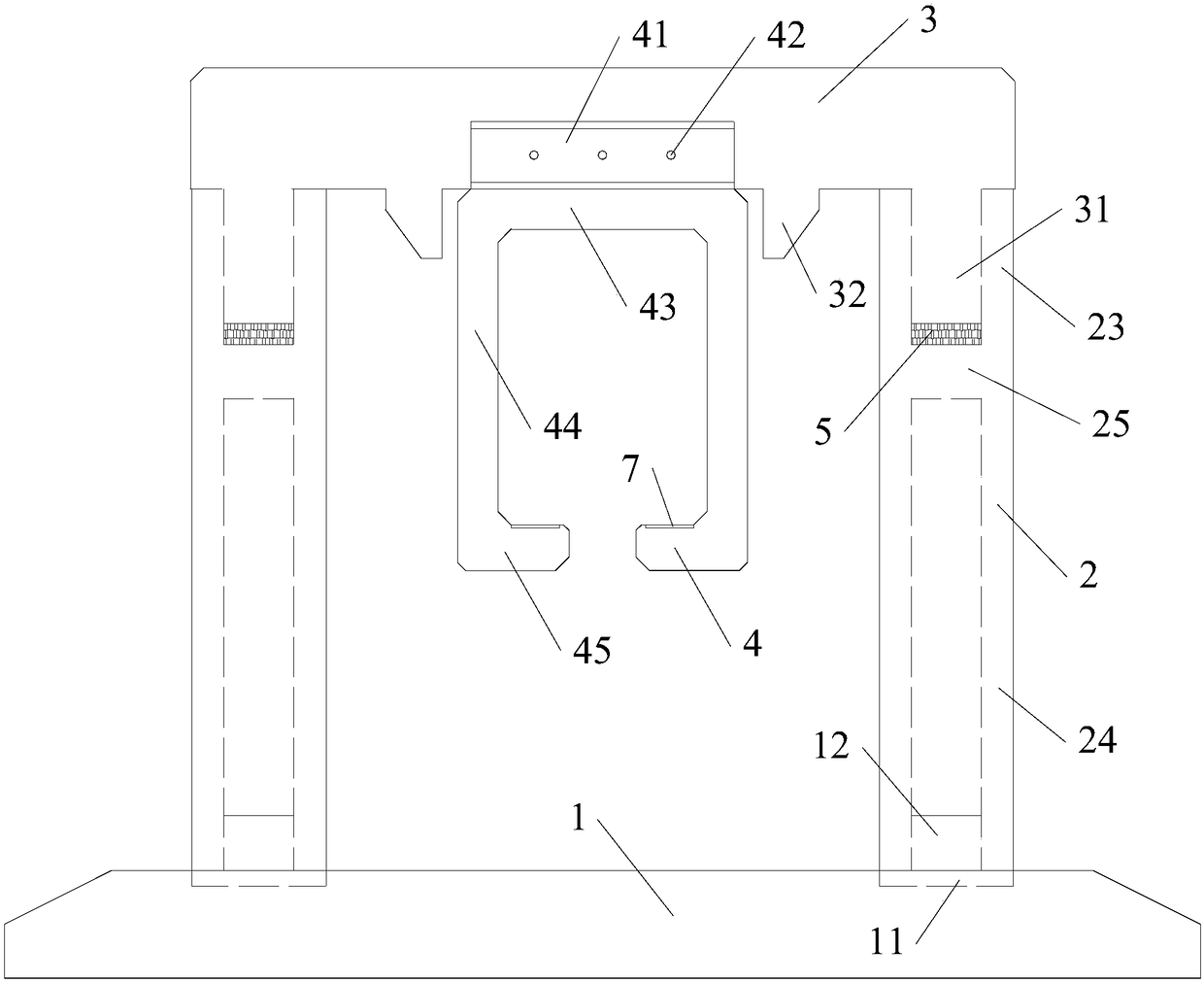

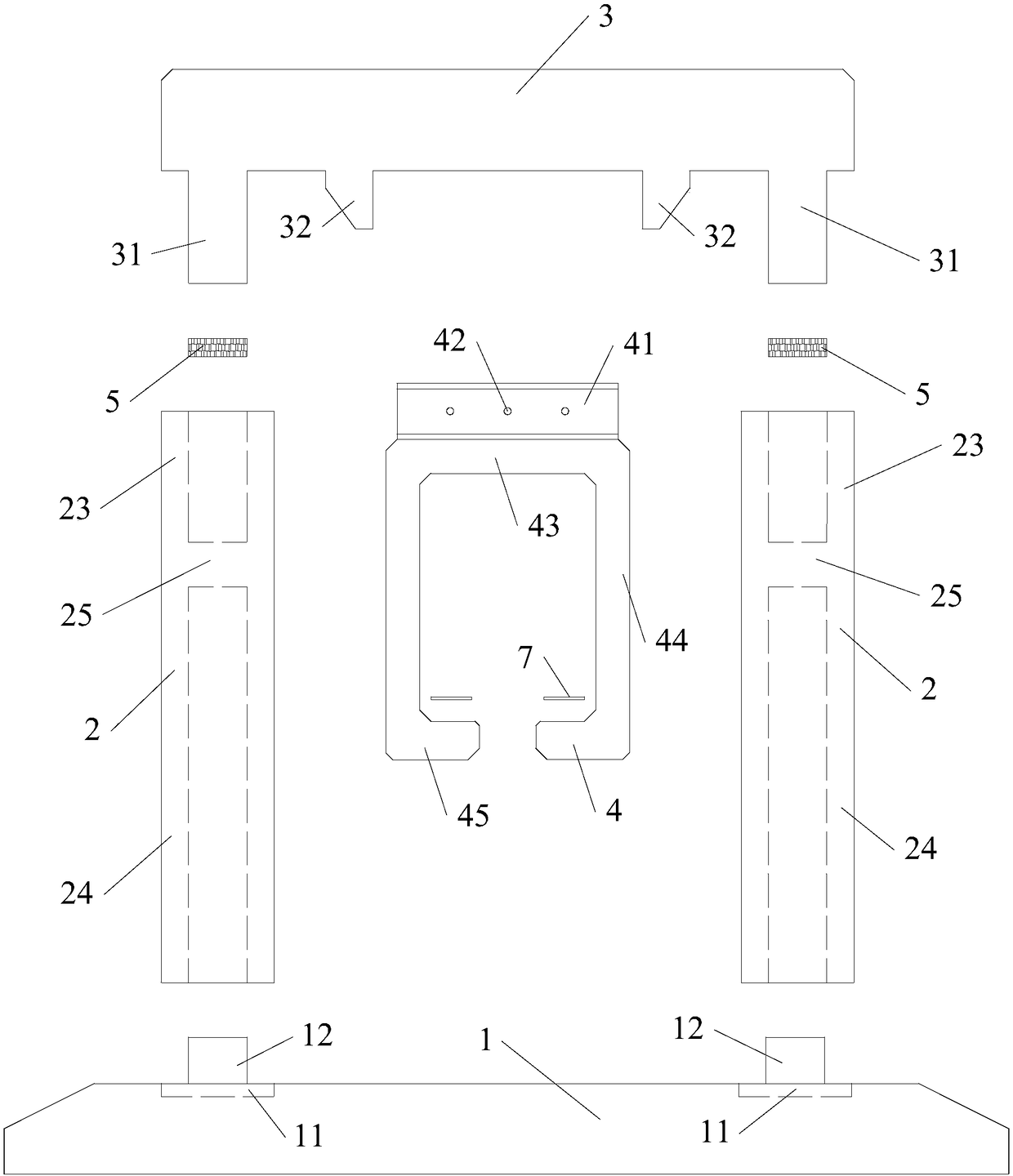

[0054] Step 1: Prefabricate the required prefabricated parts, wherein the required prefabricated parts include prefabricated raft foundation 1, prefabricated hollow concrete pier 2, prefabricated concrete beam 3 and prefabricated concrete track beam 4 four kinds of prefabricated parts. specific:

[0055] Several protrusions 13, grooves 11 and positioning piles 12 are preprocessed on the prefabricated raft foundation 1 (as Image 6 , Figure 7 shown);

[0056] The bottom of described prefabricated hollow concrete pier 2 is preprocessed with grouting hole 21 and air vent 22 (as Image 6 As shown), a pier web diaphragm 25 is pre-processed on the upper part of the prefabricated hollow concrete pier 2, and the pier web diaphragm 25 isolates the hollow part of the prefabricated hollow concrete pier 2 to form an up...

Embodiment 2

[0066] like Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that in the first step, the sleeve 14 is prefabricated on the prefabricated raft foundation 1, and in the fifth step, the prefabricated hollow The concrete pier 2 is arranged on the sleeve 14 , and concrete is poured into the sleeve 14 to connect the prefabricated raft foundation 1 and the prefabricated hollow concrete pier 2 .

[0067] In the first step, a grout hole 15 is pre-processed in the lower part of the sleeve 14. With this structure, after the sleeve 14 is connected to the prefabricated hollow concrete pier 2, the subsequent poured concrete can enter through the grout hole 15. The hollow part of the prefabricated hollow concrete pier 2 forms a stop pin structure in the hollow part to further optimize the stress of the prefabricated hollow concrete pier 2 and improve connection reliability.

Embodiment 3

[0069] like Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that in the first step, holes are pre-processed in the plug-type connection part 31 and the pier connection part 23 respectively, and in the step six, in the plug After the type connecting part 31 is inserted into the pier connecting part 23, the tensioning reinforcement 8 is installed in the tunnels corresponding to the two, and the tensioning operation is performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com