Non-excavation-type repairing construction technology of underground pipeline

A technology for underground pipelines and construction technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, coatings, etc. It can solve the problems of no working surface, frequent rupture accidents, and inability to enter the pipeline, so as to reduce maintenance costs and improve Labor efficiency, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

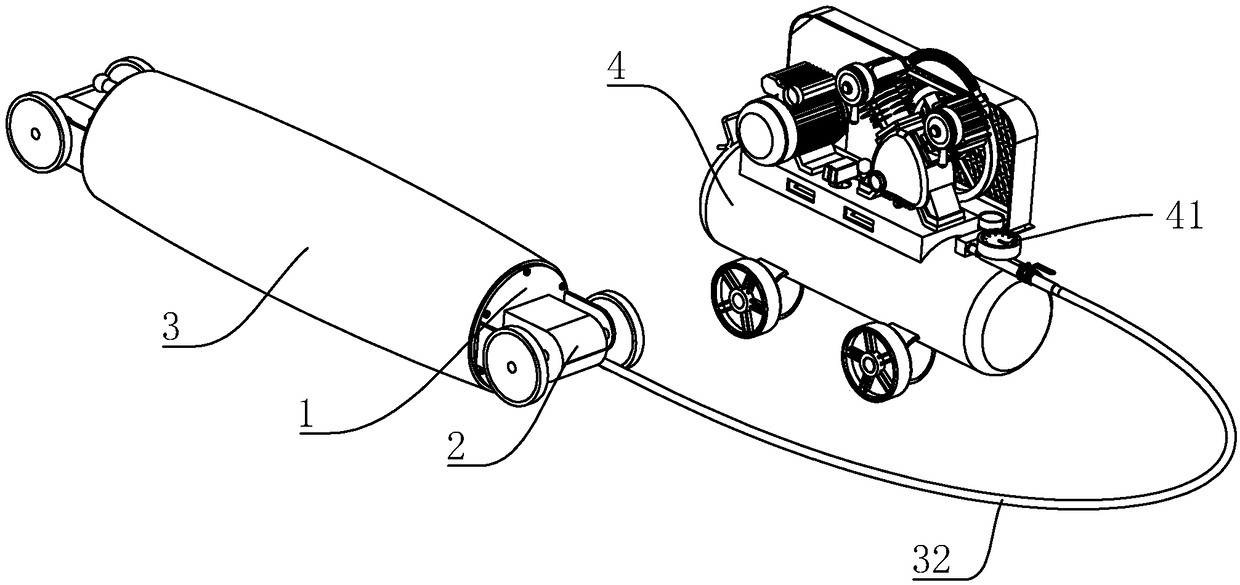

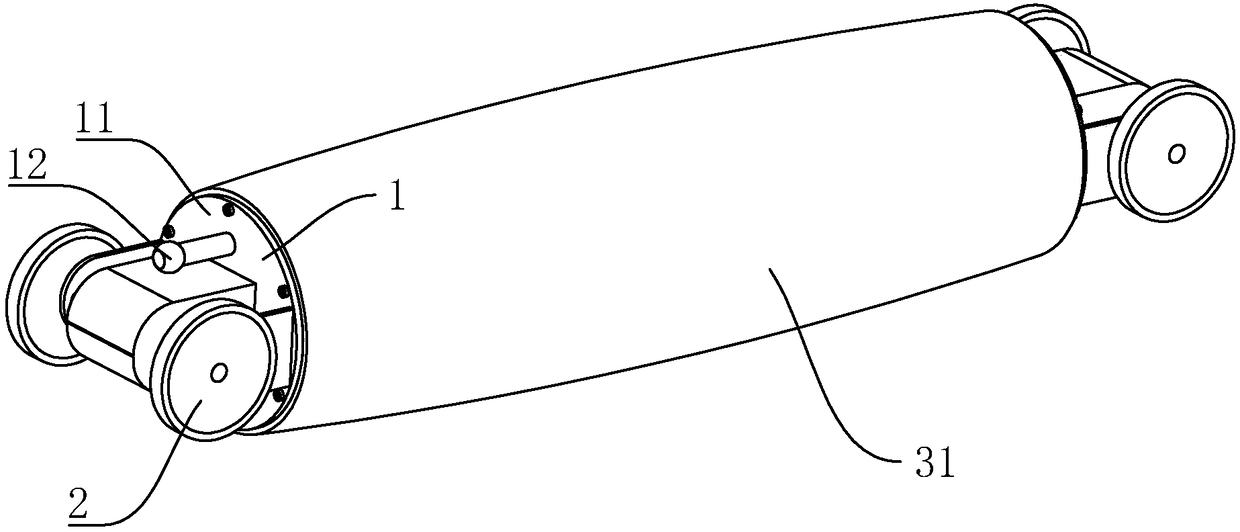

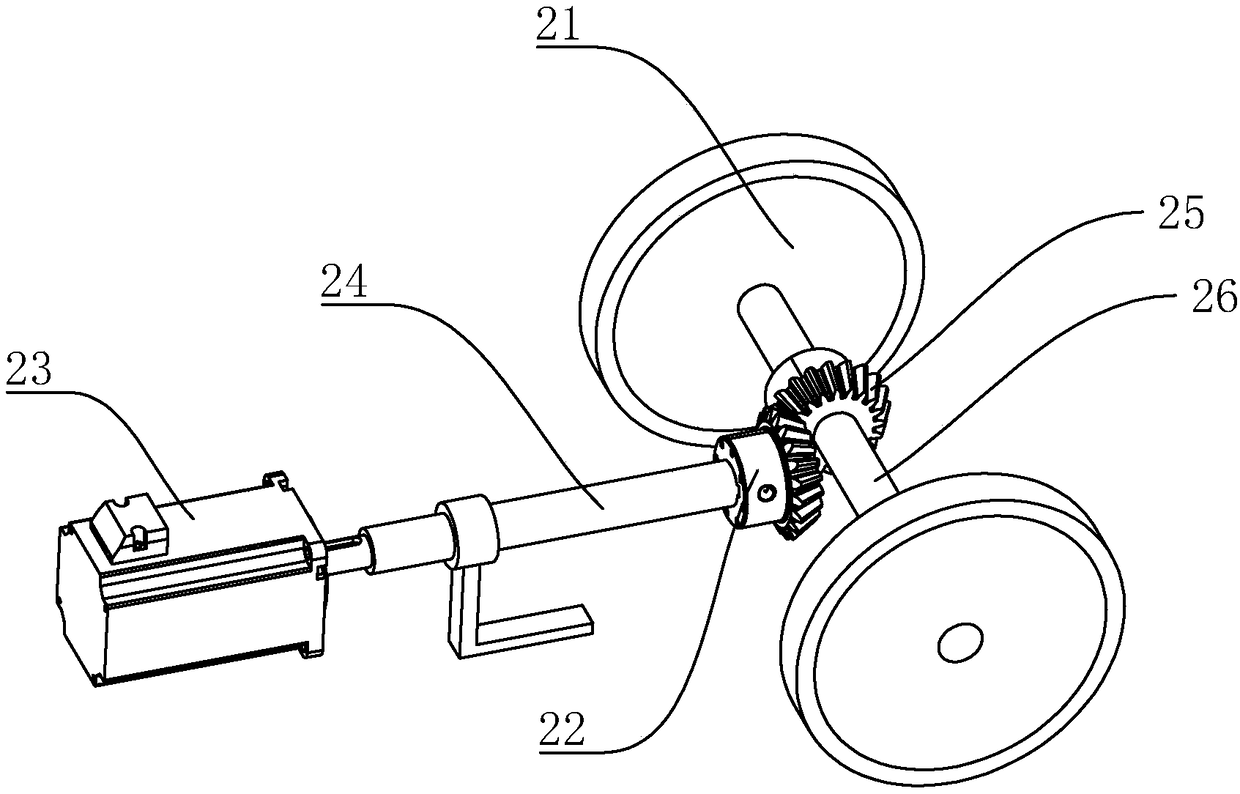

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0057] Embodiment: A kind of non-excavation repairing construction technology of underground pipeline, before starting to mend, the upstream of underground pipeline is blocked with plugging air bag or fast cement, and the upstream sewage in underground pipeline is guided to downstream by pump. The next step can only be carried out when the remaining water in the underground pipeline does not exceed 20% of the total height of the pipeline.

[0058] The specific process is as follows: S1: Prepare epoxy resin curing agent, epoxy resin curing agent is composed of A material and B material, wherein:

[0059] Material A by weight

[0060] Liquid epoxy resin 1 Propylene oxide butyl ether 0.1~0.15

[0061] Isobutyl titanate 0.01~0.02 Organic bentonite 0.05~0.2

[0062] Iron powder 0.02~0.2 Aluminum powder 0.15~0.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com