Novel ultra-thin metal snap fastener

A four-in-one, ultra-thin technology, applied in the direction of fasteners, buttons, press fasteners, etc., can solve the problems of easy detachment, unstable connection, etc., to achieve strong buckle force, improve connection stability, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

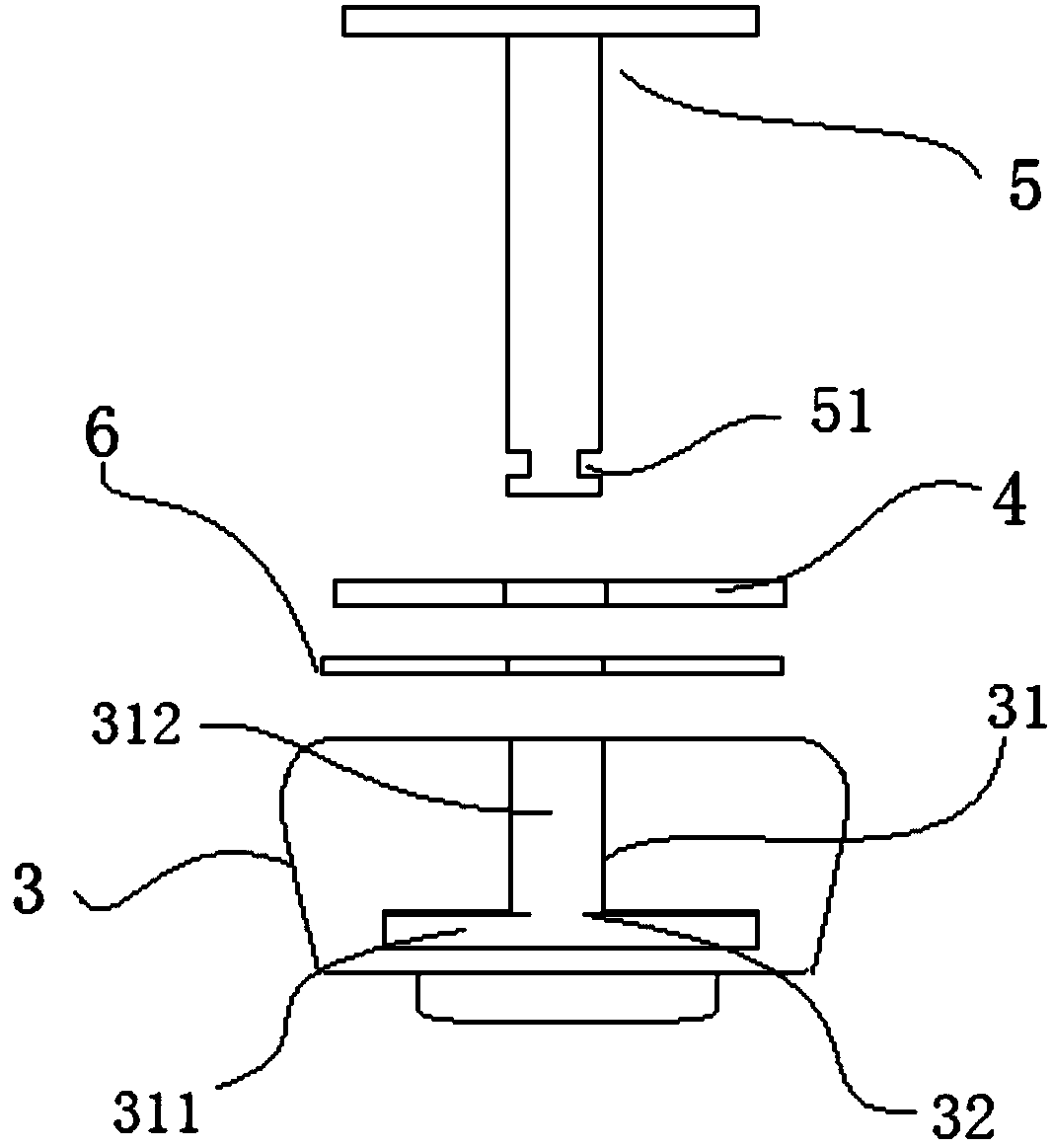

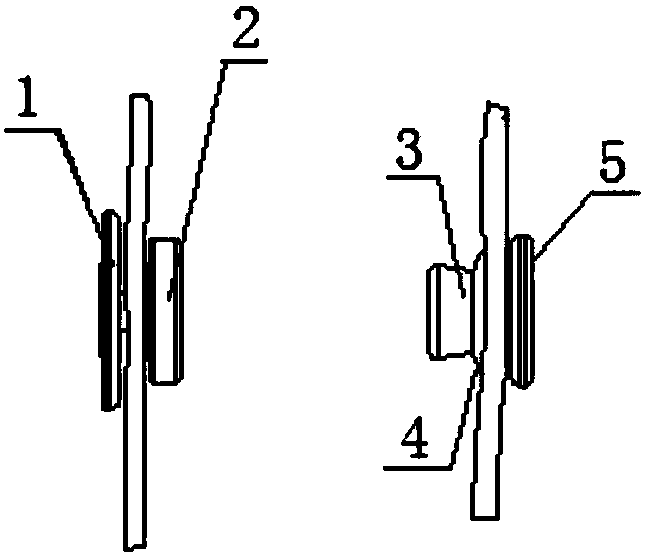

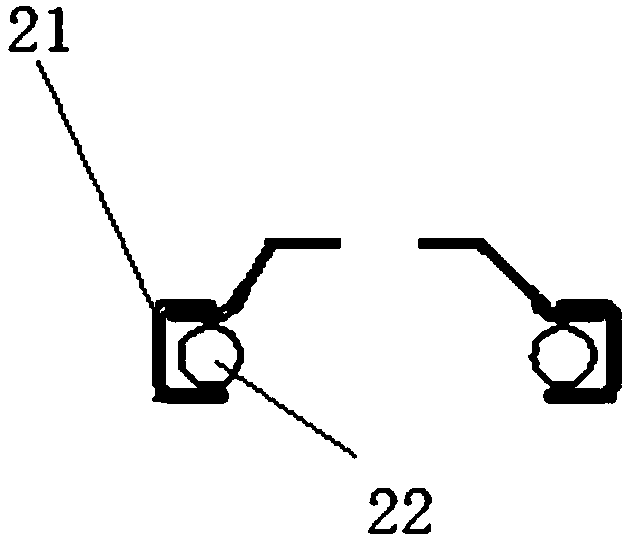

[0029] A new type of ultra-thin metal four-in-one buckle, its structure is as follows figure 2 As shown, it is composed of a male fastener and a female fastener. The female fastener includes an emergency button surface 1 and a slingshot ring 2 that are mated and connected with each other. When the button bead 3 and the alloy button bead 3 are plugged into the slingshot ring 2, the buckle between the male fastener and the female fastener is realized. The upper part of the alloy button bead 3 is processed with an inverted T-shaped hole 31, which includes an integrally connected The large hole portion 311 and the small hole portion 312 are provided with a card 32 with one end fixed to the inner wall of the large hole portion 311 and the other end stretching out to the small hole portion 312 at the junction of the large hole portion 311 and the small hole portion 312. The size of the nail 5 matches the inner diameter of the small hole 312, and the side surface of the bottom nail ...

Embodiment 2

[0035] On the basis of Embodiment 1, this embodiment further adopts the following improved design: the side of the alloy button ball 3 facing the female fastener is provided with a button bead protrusion, and the button bead protrusion includes a button with a larger diameter connected into one body. The bead surface and the cylindrical surface with a small diameter are connected, wherein the diameter of the button bead surface is not greater than the inner diameter of the annular inner groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com