Method for repairing grinding roll of cement roller press

A repair method and technology for cement rollers, applied in auxiliary devices, plasma welding equipment, auxiliary welding equipment, etc., can solve the problems of unfavorable resource saving, waste of energy, and high cost, and achieve the effect of optimizing the working environment, reducing waste, and reducing dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

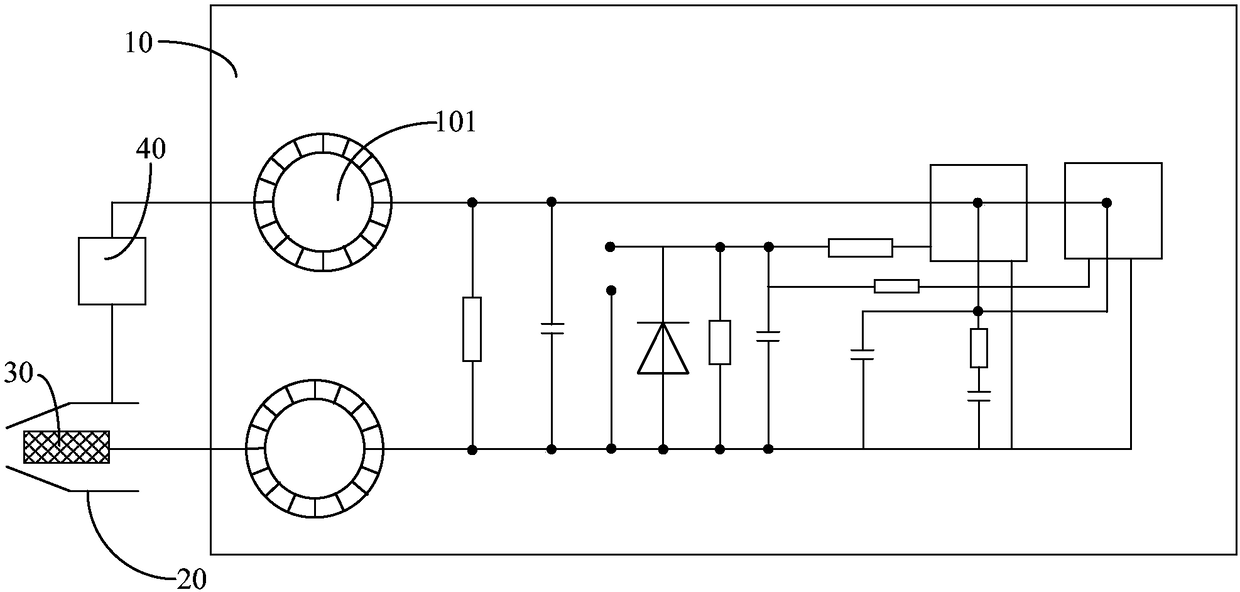

[0016] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

[0017] A method for repairing a grinding roller of a roller press comprises the following steps:

[0018] Step S001, erecting both ends of the grinding roller horizontally on the rotating device, so that the rotating device drives the grinding roller to rotate;

[0019] Step S002, aiming the nozzle of the plasma gouging machine installed on the first moving mechanism at the grinding roller, the nozzle of the plasma gouging machine is located at the first end of the grinding roller, and the nozzle is set downward, and the spraying dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com