Double-clamp drilling machine

A technology of drilling machine and drilling mechanism, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., and can solve the problems of inability to adjust the horizontal position of the drill bit at will, high labor intensity, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

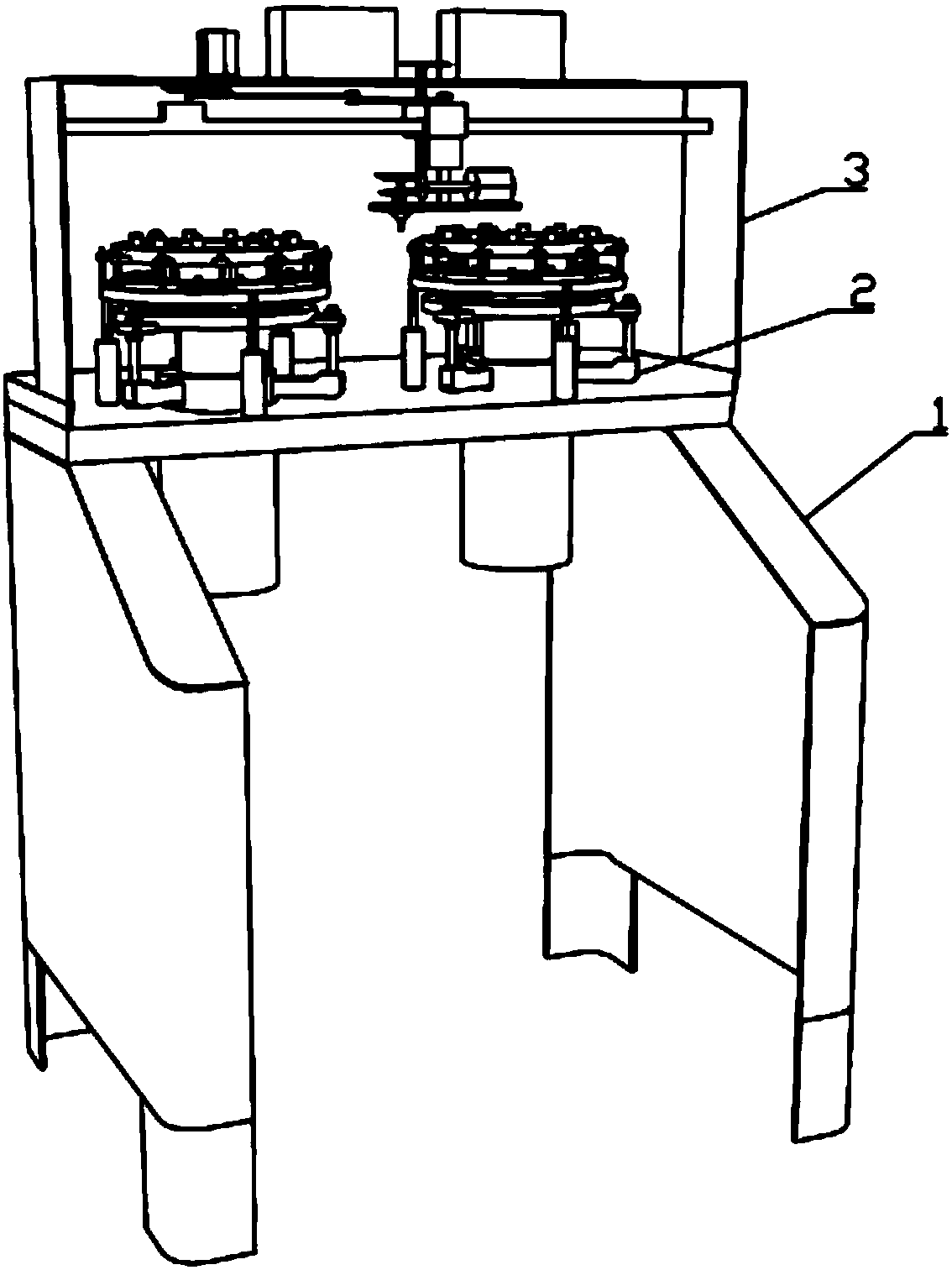

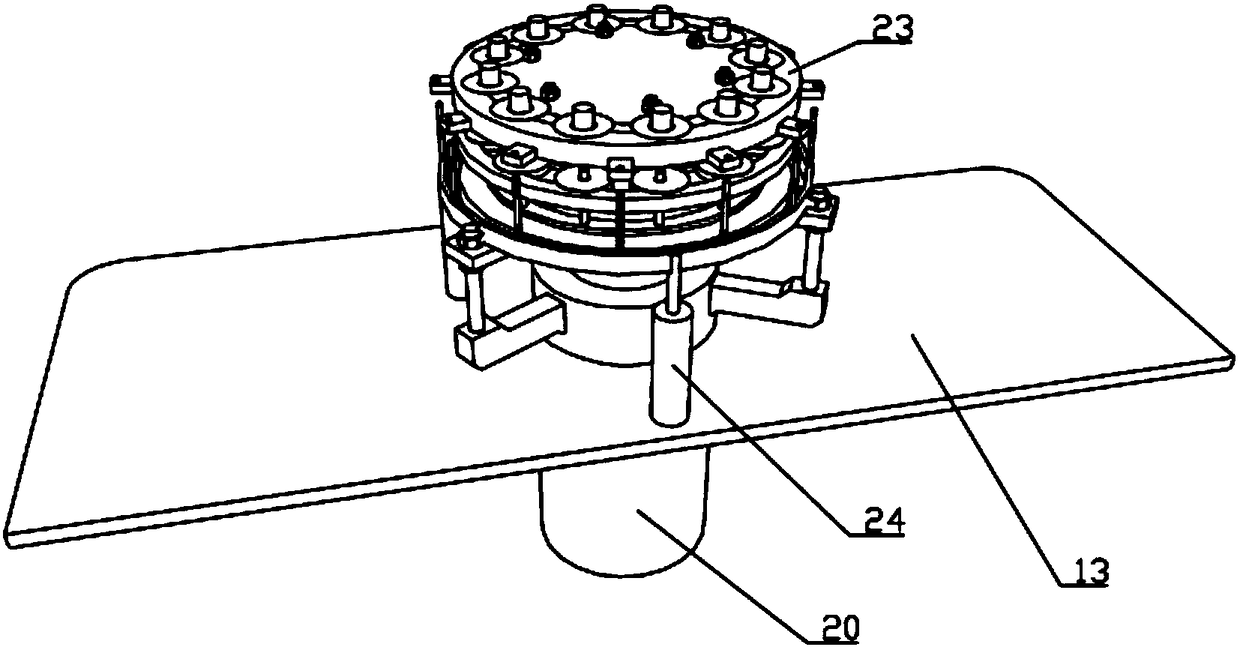

[0040] Such as Figure 1 to Figure 22 As shown, the double-clamp drilling machine of the present invention includes an operating table 1, a clamp 2 and a drilling mechanism 3;

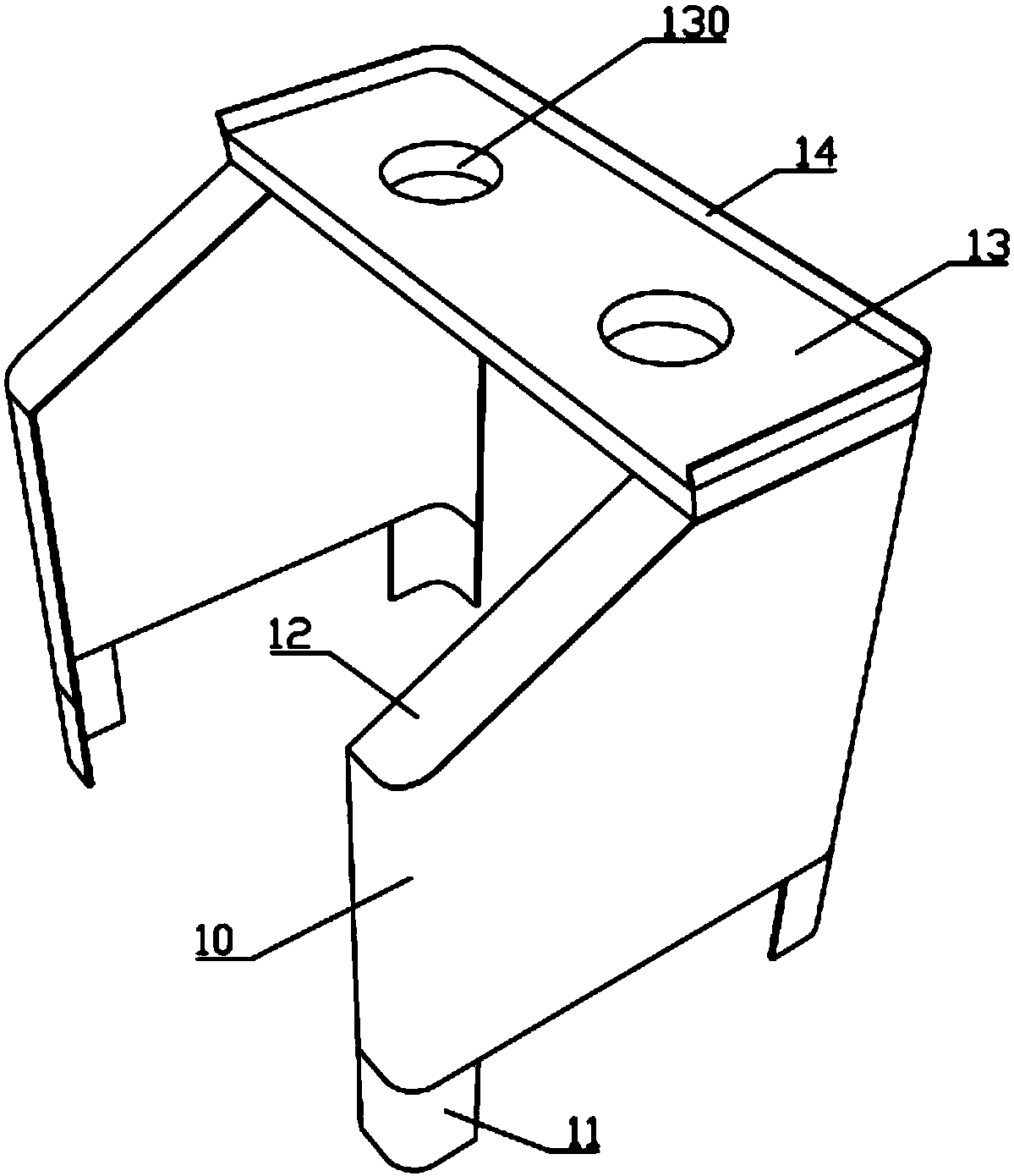

[0041] The console 1 includes a left support assembly and a right support assembly, the left and right support assemblies are symmetrical in structure, the right support assembly includes a right baffle plate 10, the cross section of the right baffle plate 10 is U-shaped and the opening is left, and the right baffle plate 10 is The bottom surface of the board 10 is horizontal, and two legs 11 are fixedly installed at the front and rear two bends. The middle and rear parts of the top surface of the right baffle 10 are horizontal, and the middle and front parts have a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com