Liquid crystal display module damping device

A technology of liquid crystal display module and shock absorbing device, which is applied in the directions of transportation and packaging, packaging of vulnerable items, types of packaged items, etc., which can solve problems such as low reliability, poor shock absorption effect, and device damage, and improve protection , improve the shock absorption effect and avoid the broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

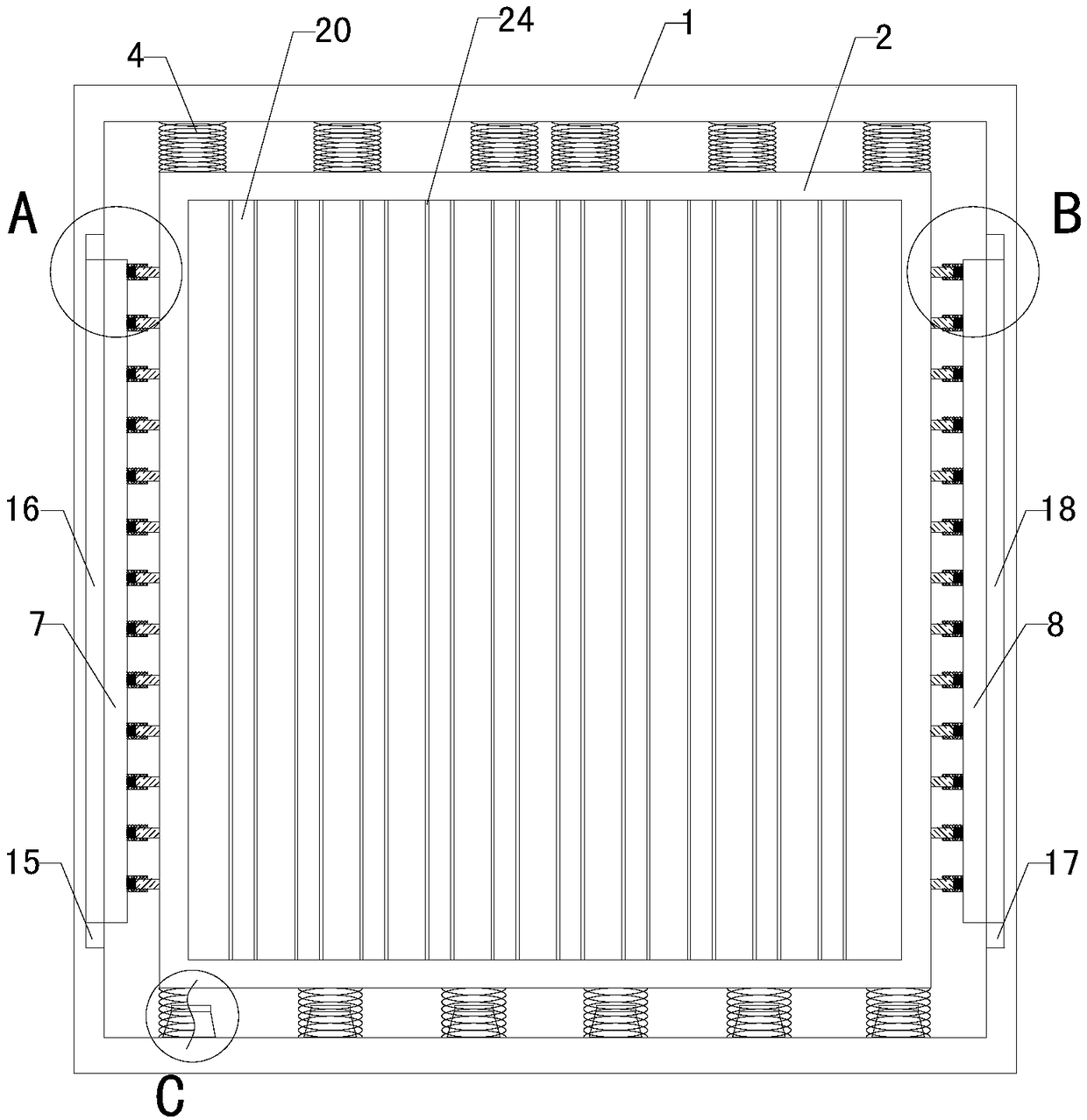

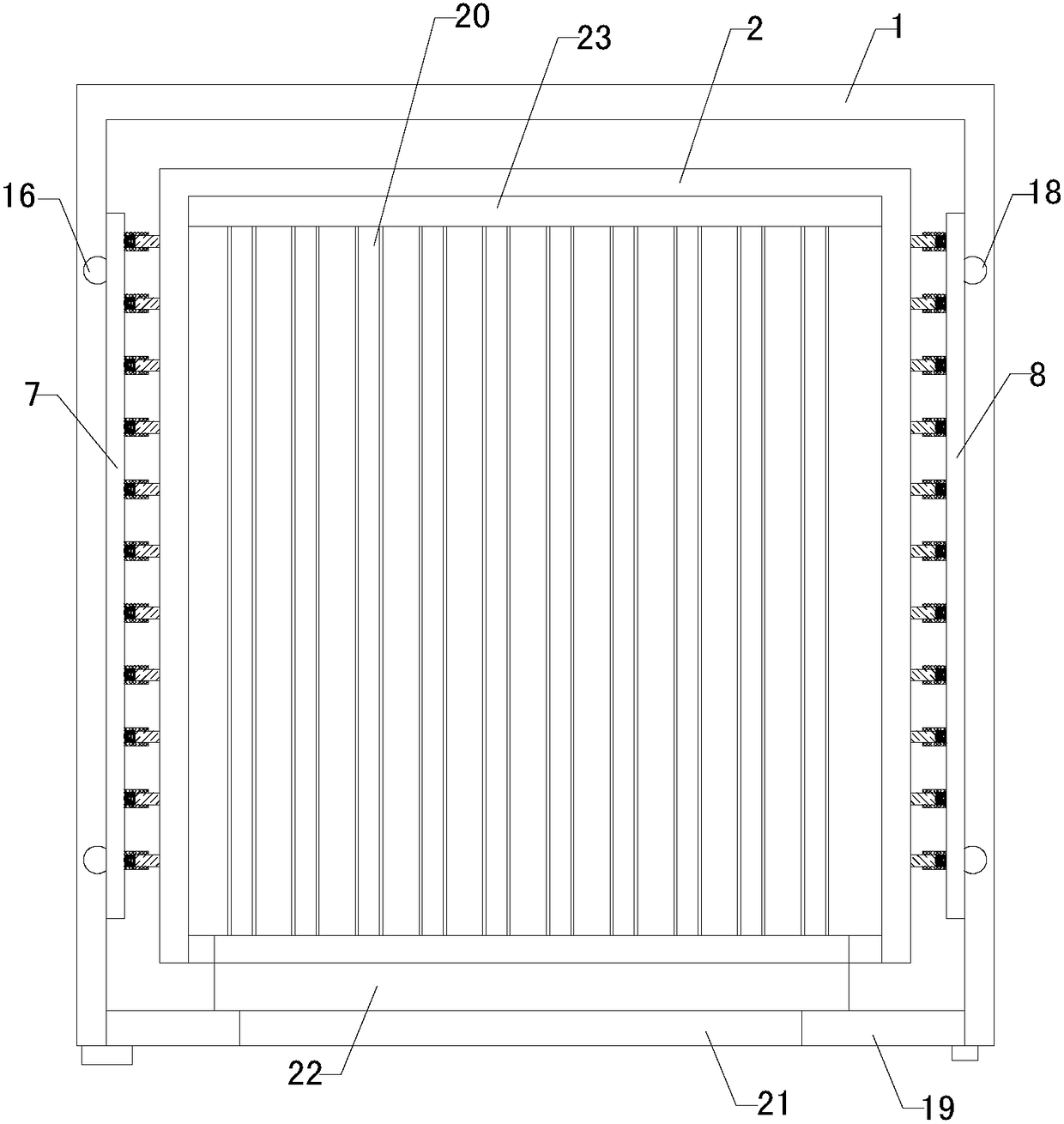

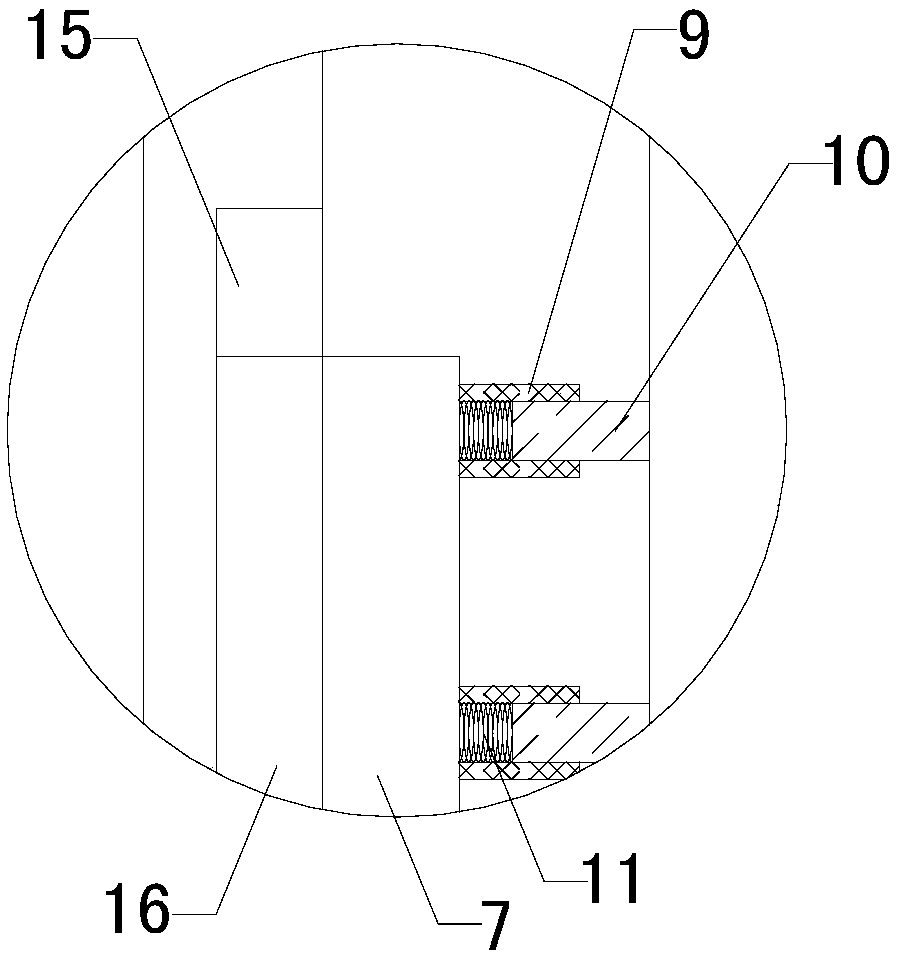

[0018] Such as Figure 1 to Figure 5 As shown, a liquid crystal display module damping device of the present invention comprises an outer box body 1, an inner box body 2, multiple sets of posts 3, multiple sets of upper springs 4 and multiple sets of lower springs 5, and the inside of the outer box body There is a placement cavity, the inner box is located in the placement cavity, the bottom ends of multiple sets of lower springs are connected with the inner bottom wall of the placement cavity, the top ends of multiple sets of lower springs are connected with the bottom end of the inner box, and multiple sets of post The bottom ends of the bottoms are all connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com