Anti-leakage garbage compression box

A garbage compression and anti-drip technology, which is applied in the direction of garbage storage, transportation and packaging, etc., can solve the problems of poor sealing effect, easy leakage of sewage, secondary pollution, etc., and achieve simple and cheap production, convenient promotion, and avoid secondary pollution. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

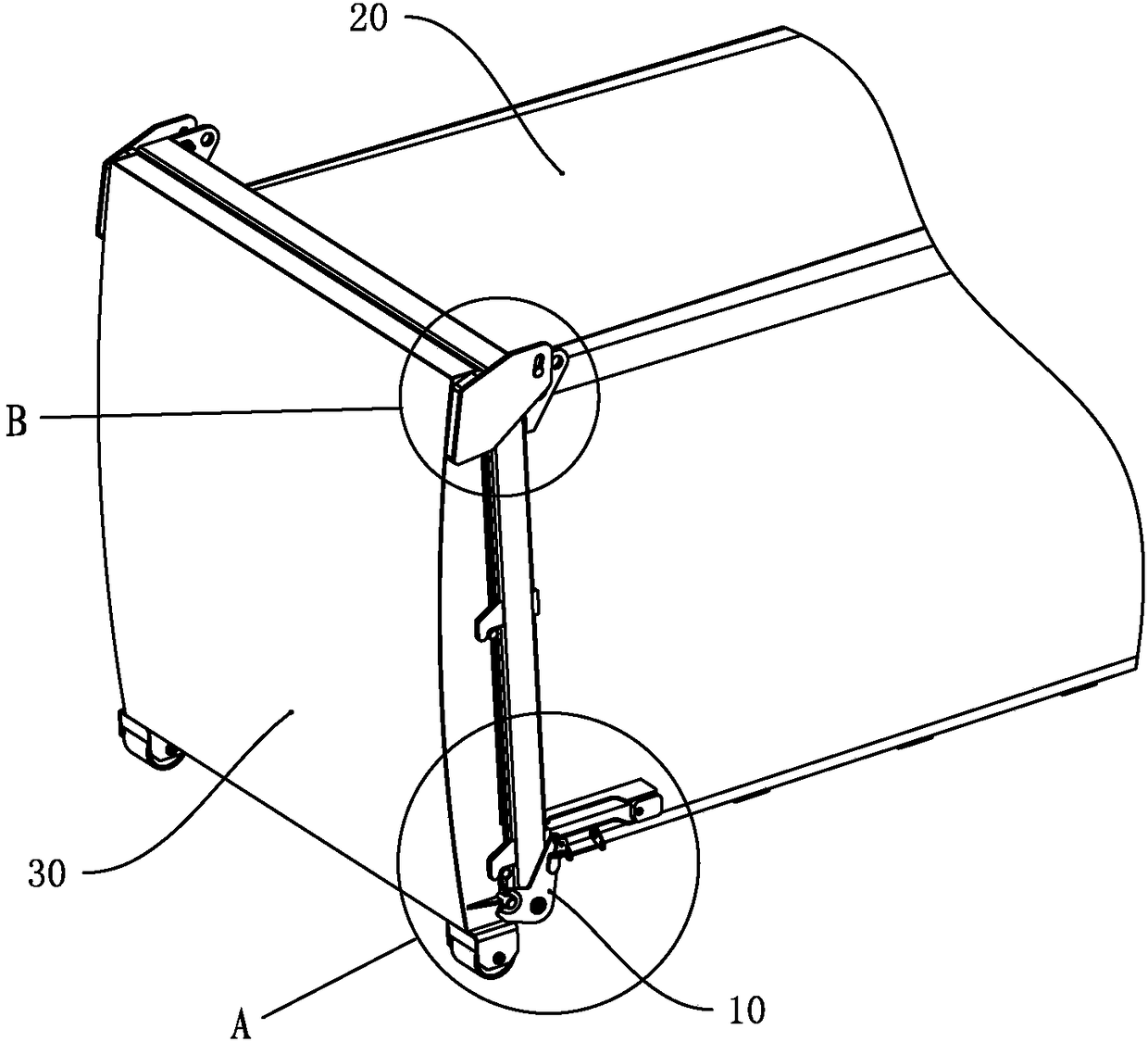

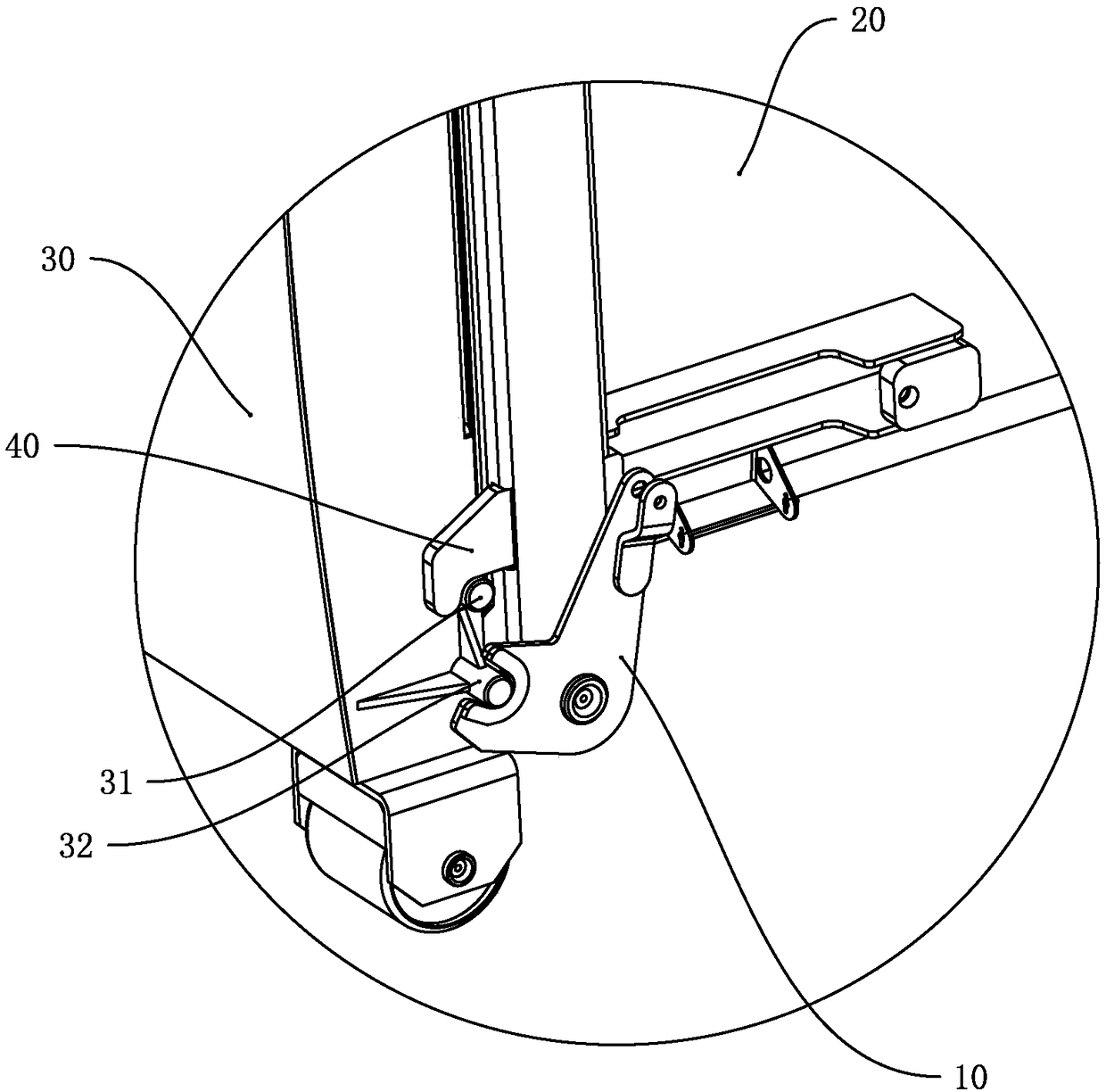

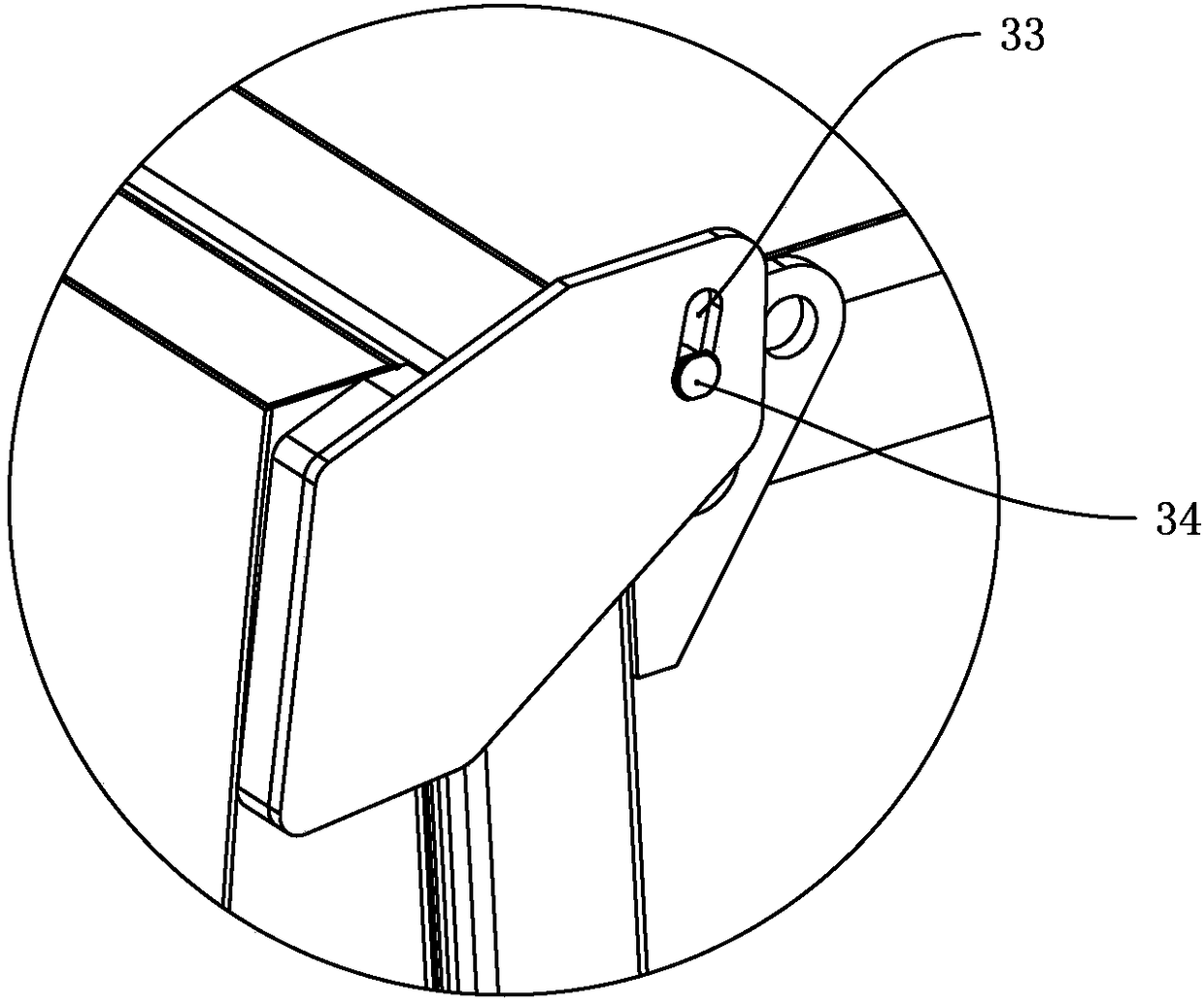

[0018] Such as Figure 1 to Figure 4 Shown, a kind of anti-drip rubbish compression box, comprise crank arm 10, telescopic mechanism, rubbish bin body 20 and rear door 30, the rear end of rubbish bin body 20 is provided with rubbish pouring outlet 21, front end is provided with rubbish pouring inlet, rear door 30 The top of the top is hinged with the top of the rear end of the garbage bin body 20, the crank arm 10 is hinged with the outer wall of the garbage bin body 20 rear end, one arm of the crank arm 10 is hinged with the telescopic shaft of the telescopic mechanism, and the other arm is provided with an opening groove 11 The outer wall of the rear end of the garbage bin body 20 is provided with a lower door hook 40, and the lower door hook 40 is close to the garbage outlet 21. One end of the lower door hook 40 is fixedly connected with the rear end of the garbage bin body 20, and the bottom of the rear door 30 is fixed with a lock. Tight shaft 31 and drive shaft 32, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com