Railway bridge protective scaffolding structure and construction method thereof

A bridge structure and protective shed technology, applied in protective equipment, buildings, etc., can solve problems such as dangerous rockfall disasters, accidents, and affecting the safe operation of trains, and achieve the effect of ensuring safe operation and reasonable and effective construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in combination with specific embodiments.

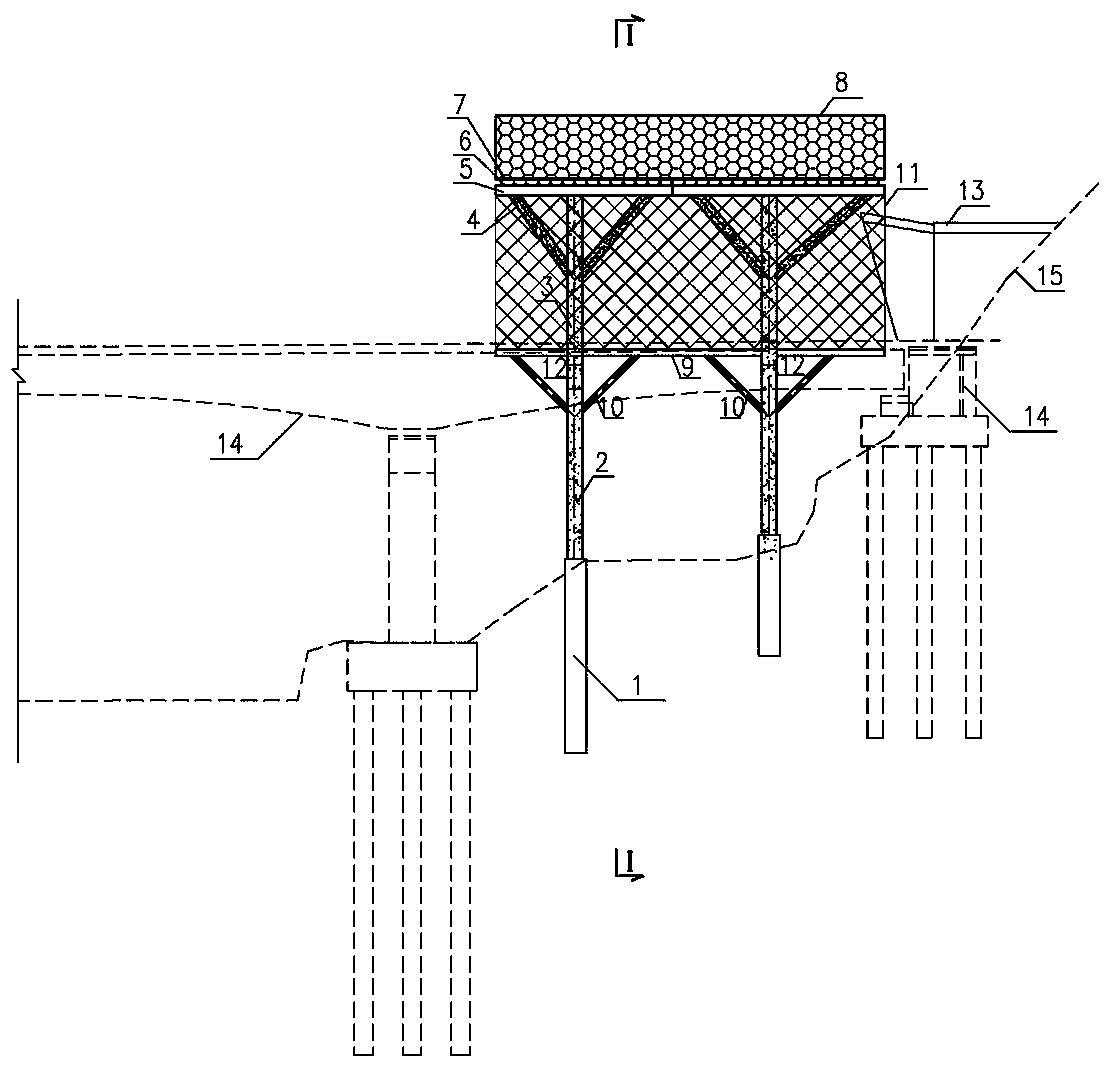

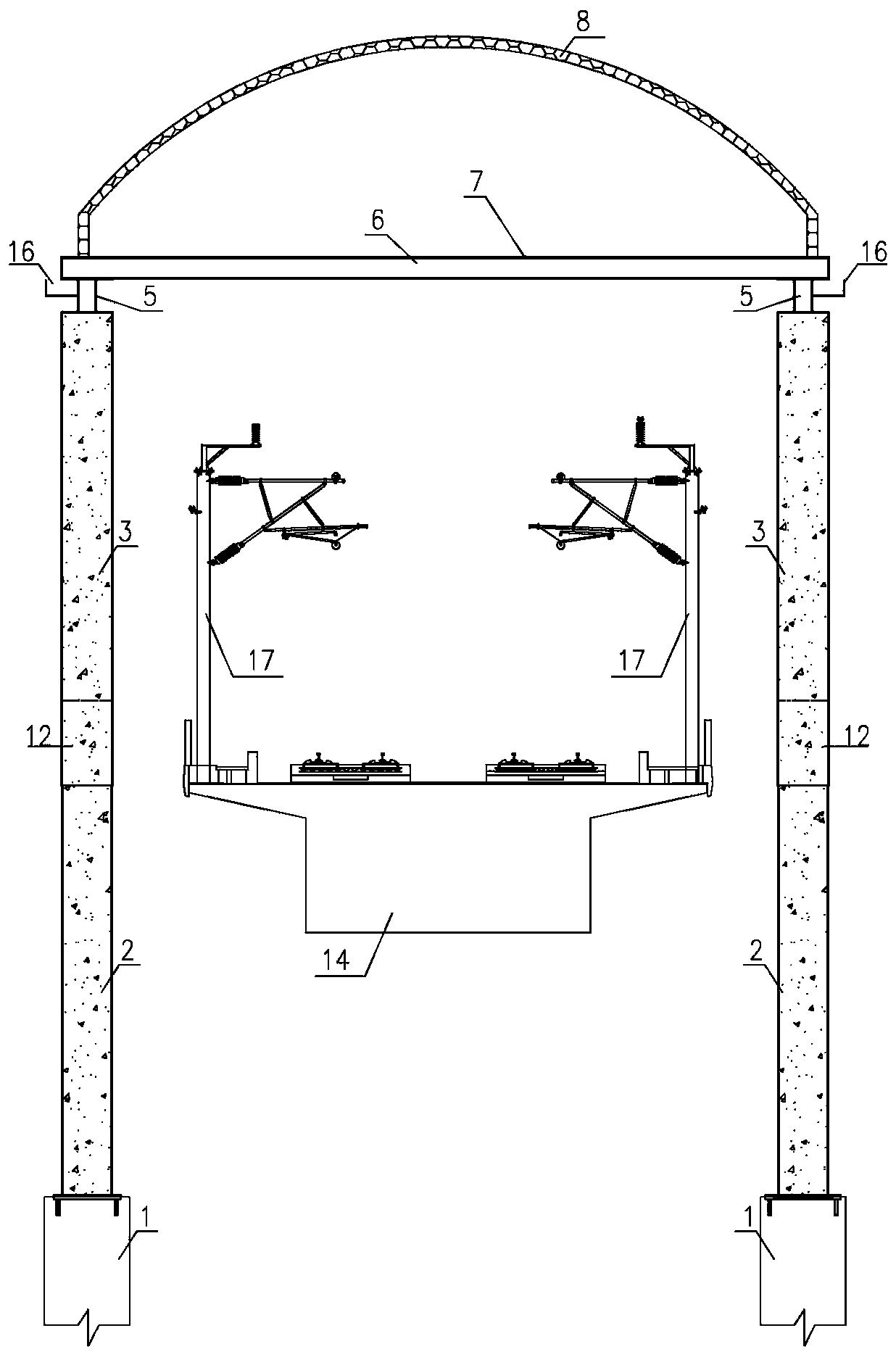

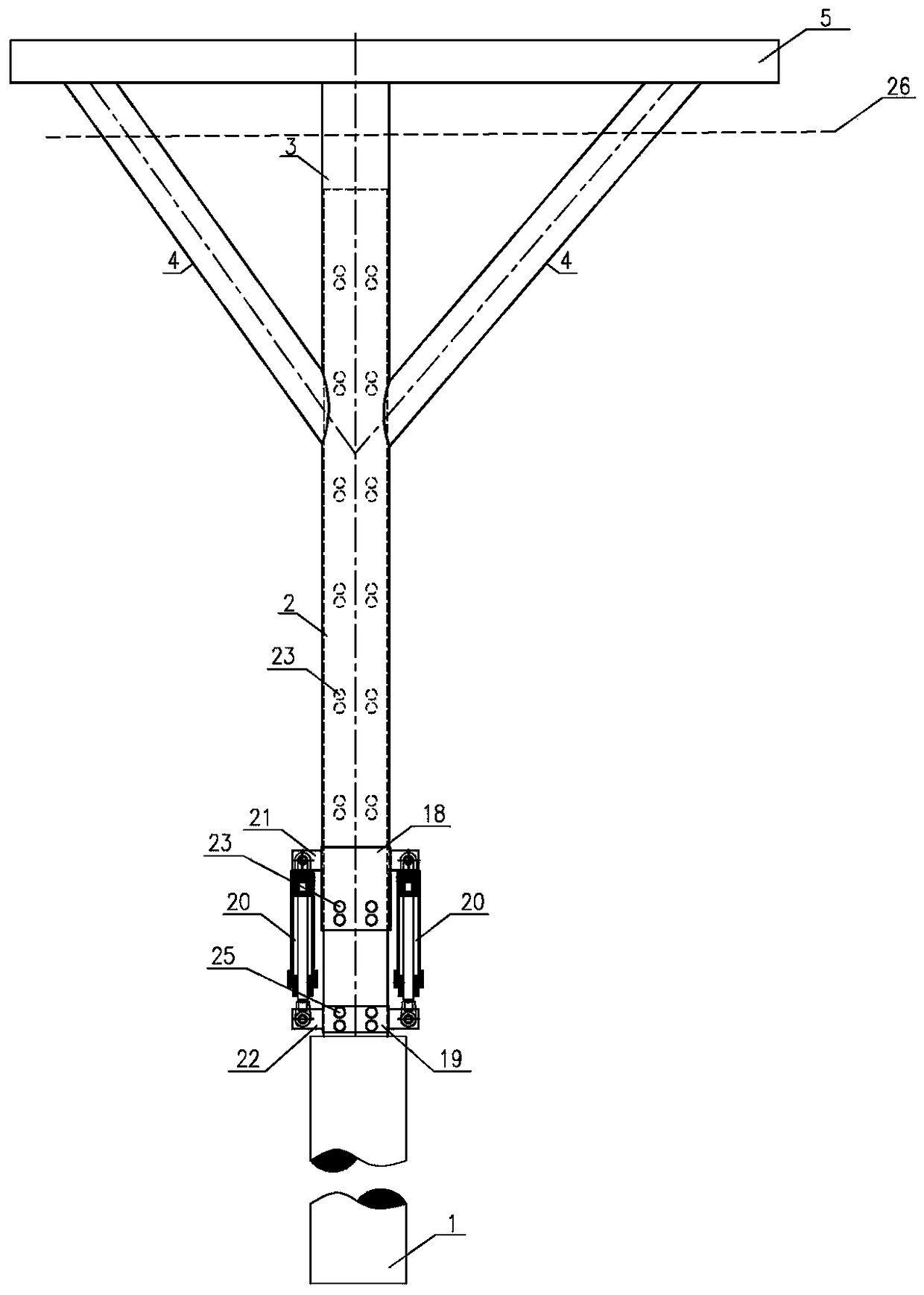

[0033] The invention relates to a protective scaffolding structure for a railway bridge. Two rows of pile foundations 1 are vertically arranged in the ground on both sides of the existing line bridge structure 14 outside the tunnel opening 13, the steel pipe concrete column is arranged above the pile foundation 1, and the top of the steel pipe concrete column is arranged. Steel longitudinal beams 5 and arched flexible shed holes 8 are arranged between the tops of the steel longitudinal beams 5 on both sides. The concrete-filled steel tube column is located at the height of the bridge deck of the existing line bridge structure 14 and is provided with a longitudinal protective net cross brace 9 , and a protective net 11 is arranged on the steel tube concrete column above the protective net cross brace 9 .

[0034] A vertical pushing member is arranged on the steel tube conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com