Electromagnetic fan clutch

An electromagnetic fan and clutch technology, which is applied in the direction of machines/engines, coolant flow control, engine components, etc., can solve the problem of wire retention between the iron core part and the pulley, the deterioration of the compactness of the fan clutch, and the reduction of the assembly process Convenience and other issues, achieve good fixing effect, reduce load, and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

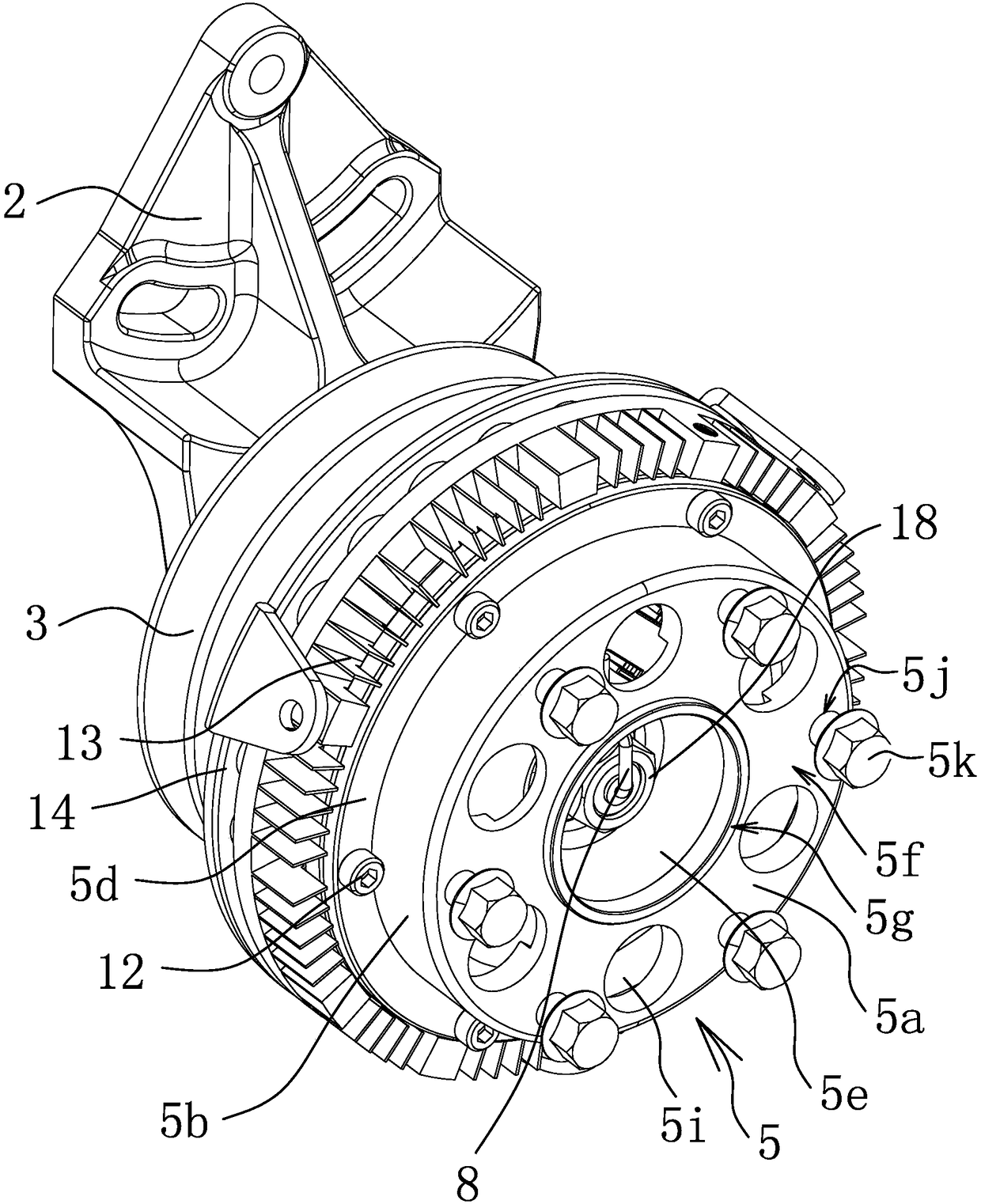

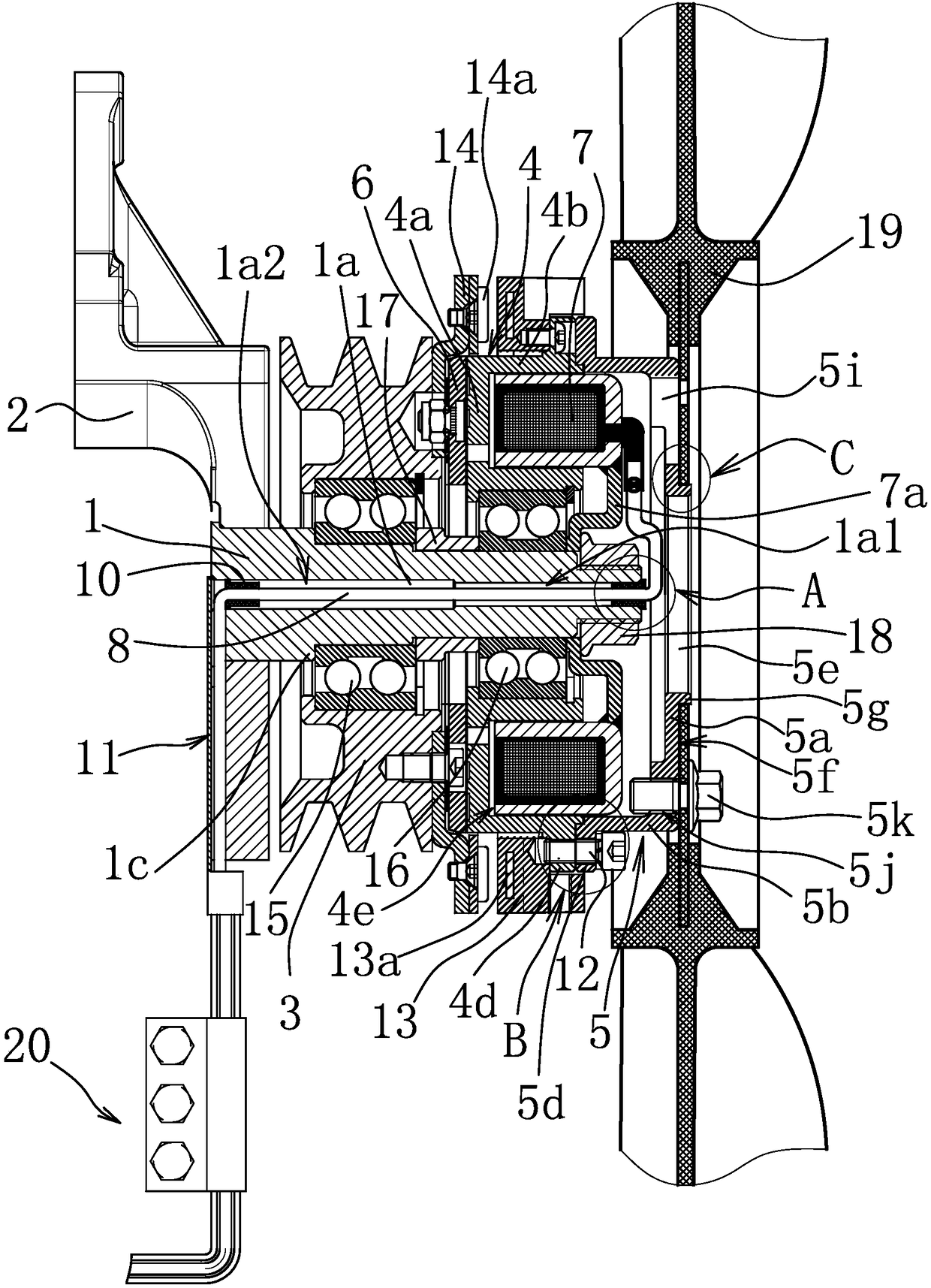

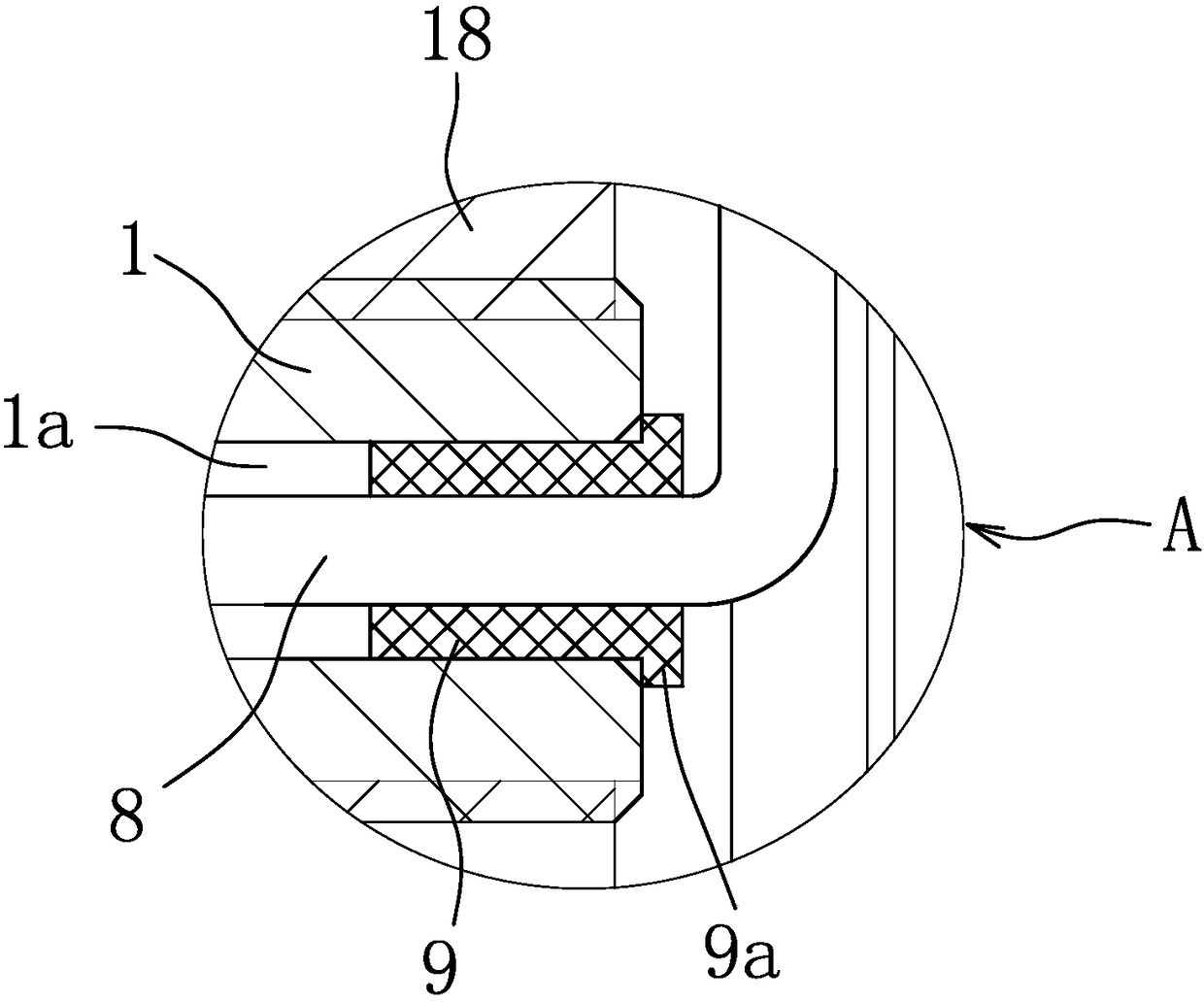

[0053] like Figure 1-Figure 6 As shown, an electromagnetic fan clutch includes a swing arm shaft 1, the rear end of the swing arm shaft 1 is sheathed and fixed with a swing arm frame 2, and the electromagnetic fan clutch is fixed beside the engine through the swing arm frame 2. The swing arm shaft 1 is also sheathed with a pulley 3 and a magnetic disk 4, both of which are rotatably connected to the swing arm shaft 1, and the pulley 3 is located between the swing arm frame 2 and the magnetic disk 4. A bearing one 15 is arranged between the pulley 3 and the swing arm shaft 1, a bearing two 16 is arranged between the magnetic disk 4 and the swing arm shaft 1, and a bearing two 16 is arranged between the swing arm shaft 1 and the bearing one 15 and the bearing two 16. Spacer 17. Both sides of the disk 4 are correspondingly provided with a coupling assembly 6 and a coil core assembly 7 , the coupling assembly 6 is connected to the pulley 3 , and the coil core assembly 7 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com