Dual-frequency dual-channel wireless triggering transmission line inspection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

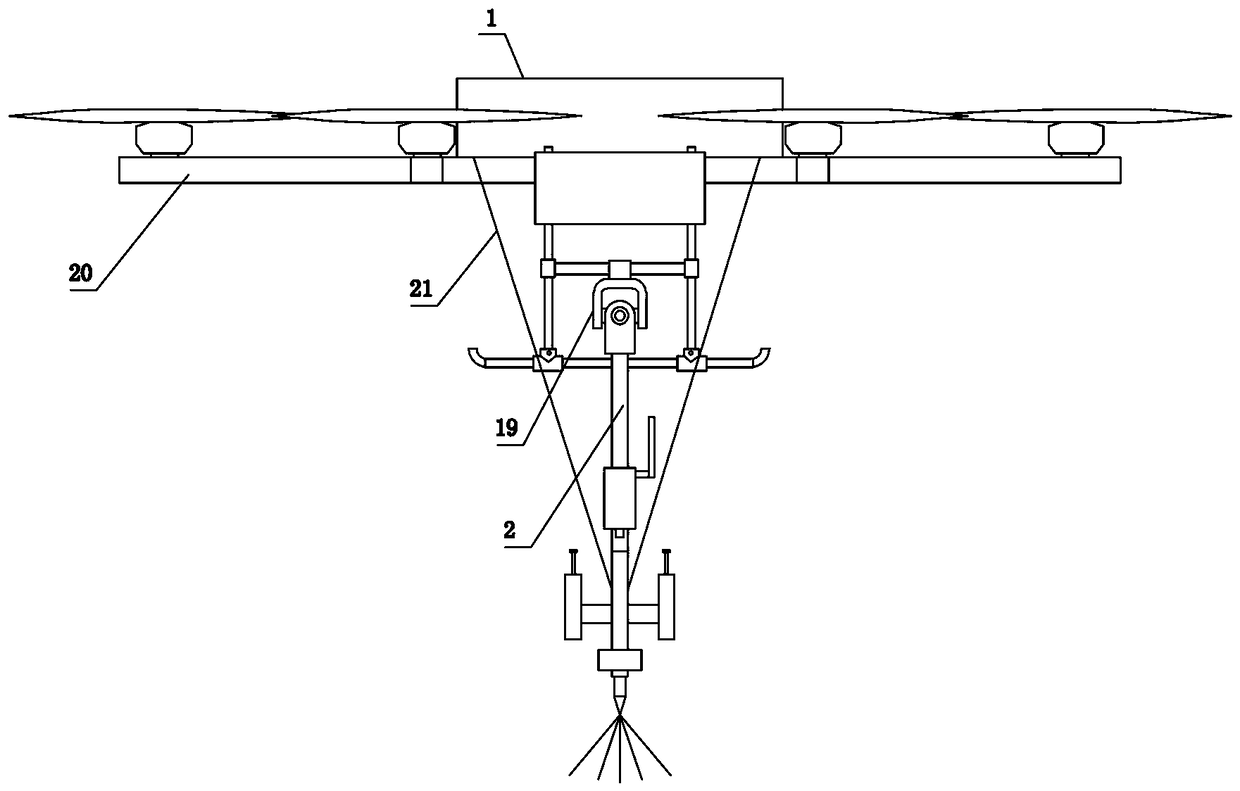

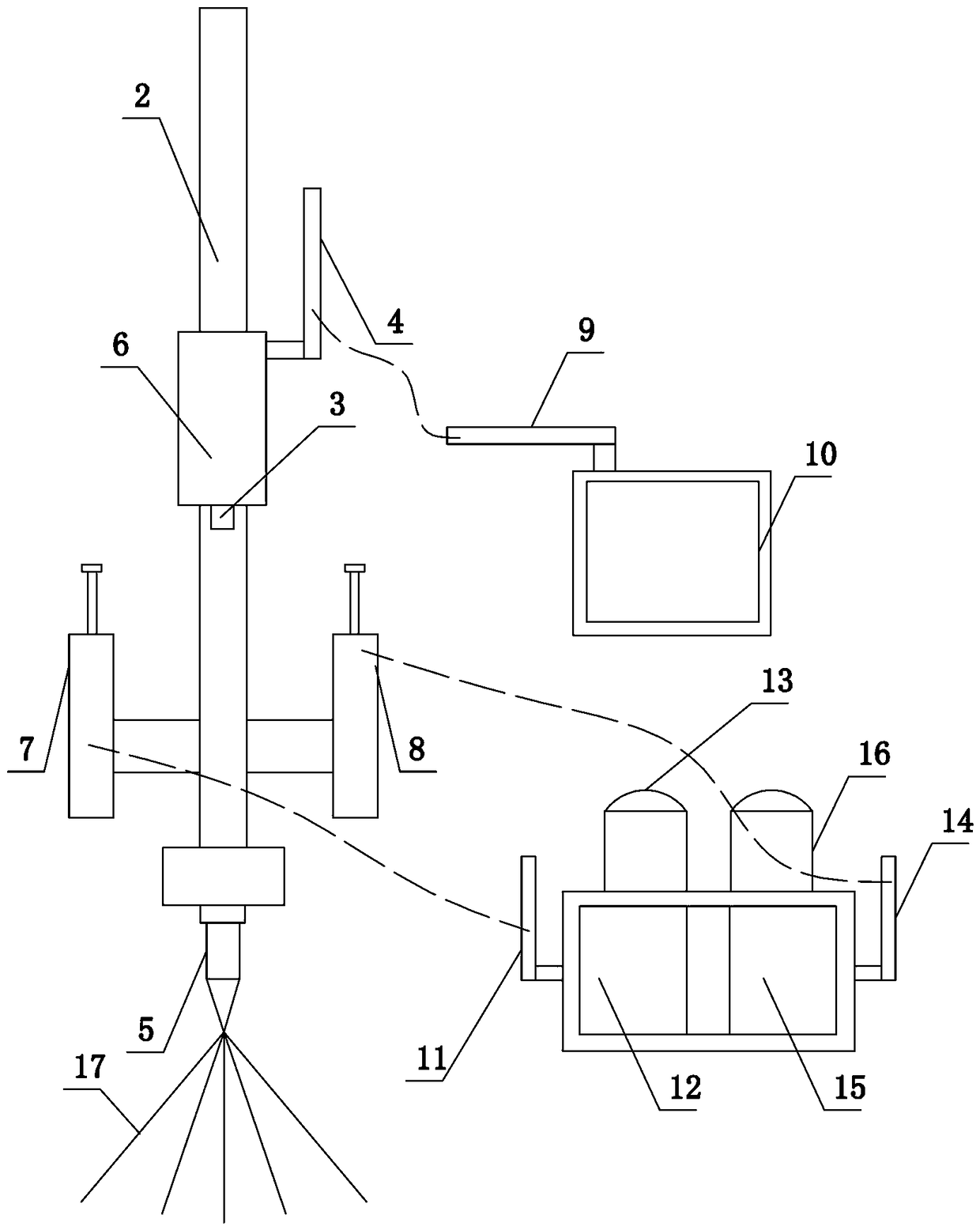

[0028] like Figure 1 to Figure 3 As shown, the present invention includes an aerial electrical inspection system and a ground monitoring system. The aerial electrical inspection system includes an unmanned aerial vehicle 1 and an insulating pole 2. The unmanned aerial vehicle 1 adopts a six-rotor unmanned aerial vehicle, and the insulating pole 2 passes through a cross-axis universal joint 19 Installed on the horizontal carbon tube of the six-rotor UAV, on the one hand, this structure facilitates the rapid electrical inspection of the insulating rod 2, and on the other hand, it can realize the front and rear flip hinge of the insulating rod 2, so as to avoid the influence of the insulating rod 2 on the lifting of the UAV. In the process, two pull ropes 21 are set between the support arm 20 of the six-rotor UAV and the insulating rod 2, and the two pull ropes 21 and the insulating rod 2 form a tapered structure, which is used to prevent the insulating rod 2 from swinging left a...

Embodiment 2

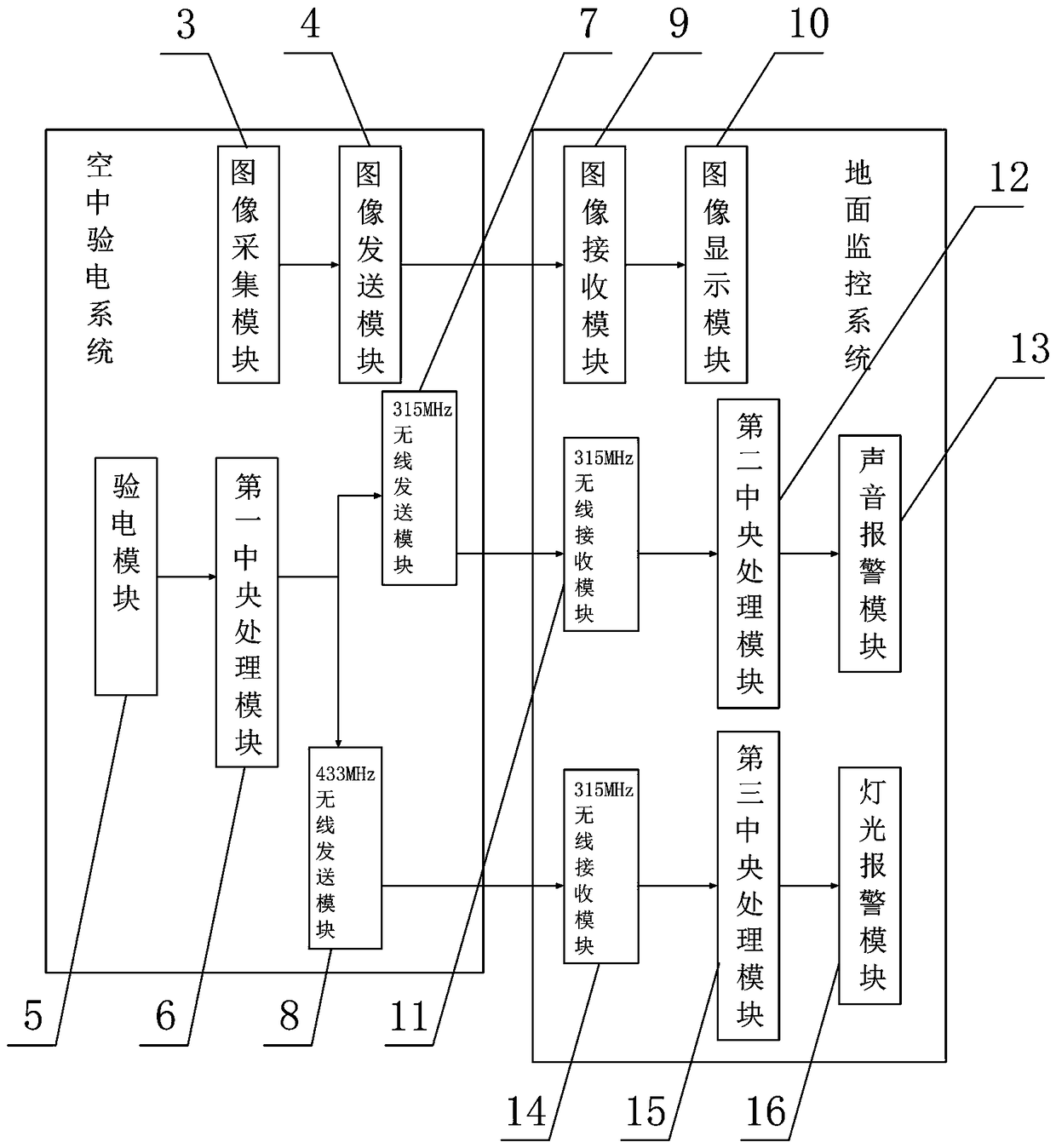

[0038] like figure 1 and figure 2 As shown, the present invention includes an aerial electrical inspection system and a ground monitoring system. The aerial electrical inspection system includes an unmanned aerial vehicle 1 and an insulating pole 2 installed on the unmanned aerial vehicle 1. The unmanned aerial vehicle 1 adopts a multi-rotor unmanned aerial vehicle, and the insulating pole 2 is equipped with an image acquisition module 3, an image transmission module 4, an electrical inspection module 5, a signal conditioning module 18, a first central processing module 6, a 315MHz wireless transmission module 7 and a 433MHz wireless transmission module 8, and the ground monitoring system includes an image reception module 9 , image display module 10, 315MHz wireless receiving module 11, the second central processing module 12, sound alarm module 13, 433MHz wireless receiving module 14, the third central processing module 15, light alarm module 16, 315MHz wireless receiving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com