Anti-shrinkage lithium battery diaphragm

A lithium battery diaphragm and anti-shrinkage technology, which is applied to battery pack components, separators/films/diaphragms/spacers, circuits, etc., can solve lithium battery short circuit, lithium battery explosion, lithium battery temperature rise and other problems, Achieve high safety, improve cycle life, and strong wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

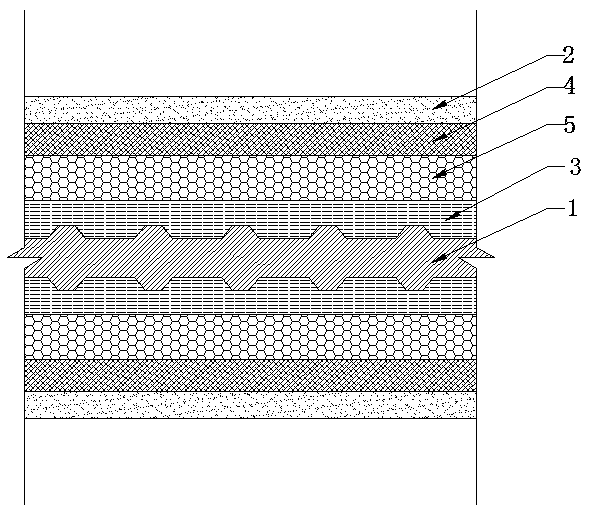

[0015] as attached figure 1 As shown, an anti-shrinkage lithium battery separator includes a substrate separator 1, a ceramic coating 2, a flame-retardant layer 3, an anti-corrosion layer 4, and a heat-insulating layer 5, and the flame-retardant layers are respectively arranged on both sides of the substrate separator 1 3. The heat insulation layer 5 outside the flame retardant layer 3, the anticorrosion layer 4 is arranged on the outside of the heat insulation layer 5, the ceramic coating 2 is arranged on the outside of the anticorrosion layer 4, and the upper and lower sides of the base material diaphragm 1 Trapezoidal protrusions are respectively provided on the surface, and trapezoidal grooves are provided at corresponding positions on the side where the flame retardant layer 3 is in contact with the substrate membrane 1 .

[0016] The base separator 1 is a PEPP composite film.

[0017] The flame retardant layer 3 is a polyamide resin layer.

[0018] The heat insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com