Energy-saving and heat preservation inner pot, method for manufacturing same and electric heating pot

An inner pot and integrated technology, which is applied to the special materials of cooking utensils, the structure of cooking utensils, cooking utensils, etc., can solve the problems of impact resistance, heat preservation and energy-saving performance, and achieve impact resistance, light weight, portability, and molding Convenience and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

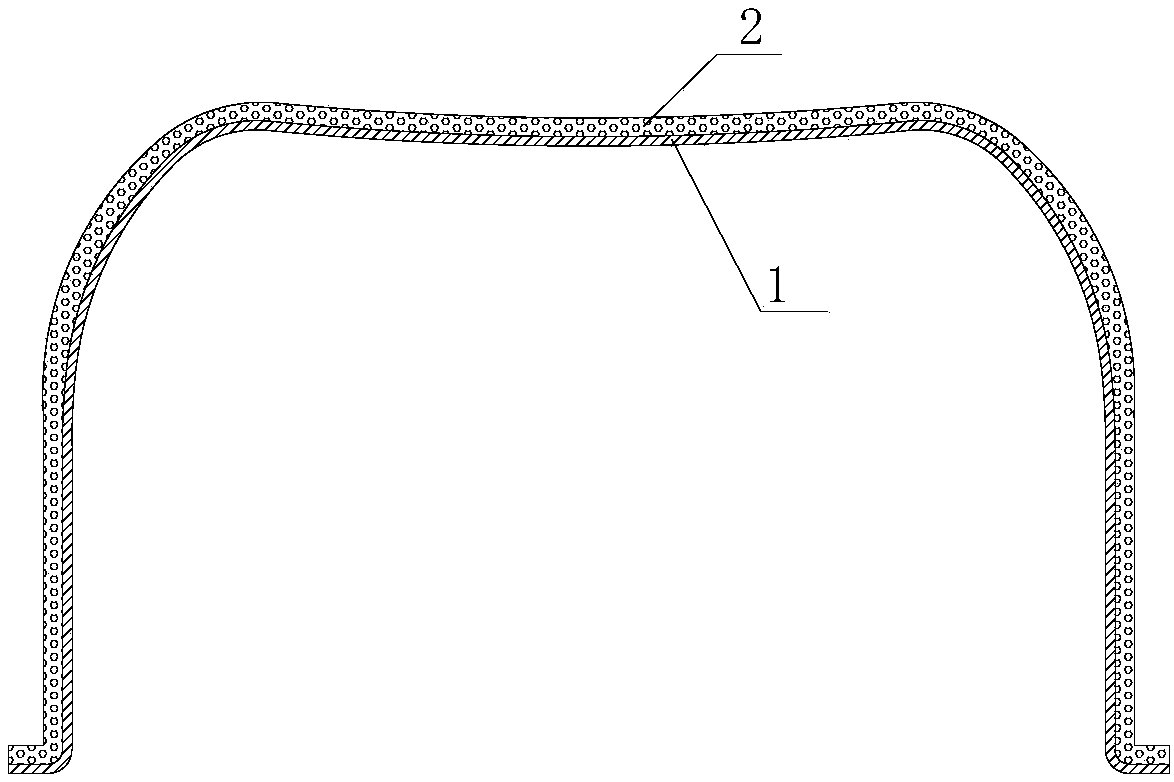

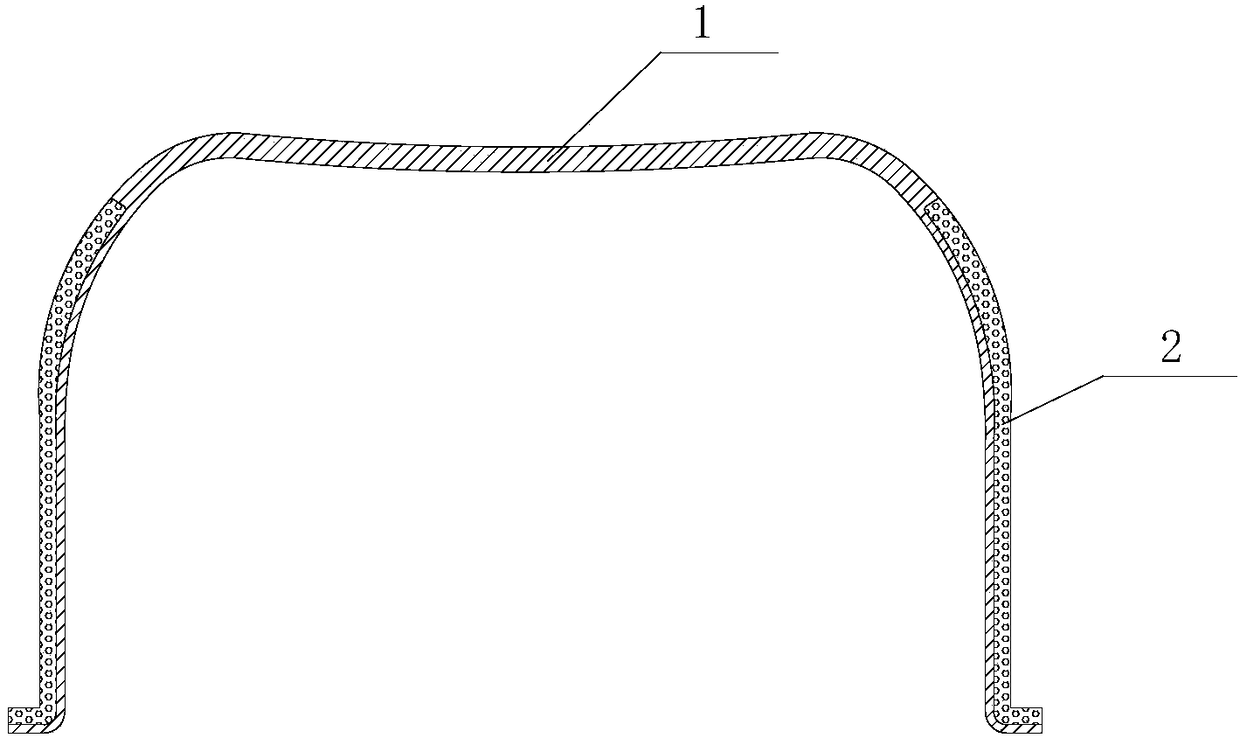

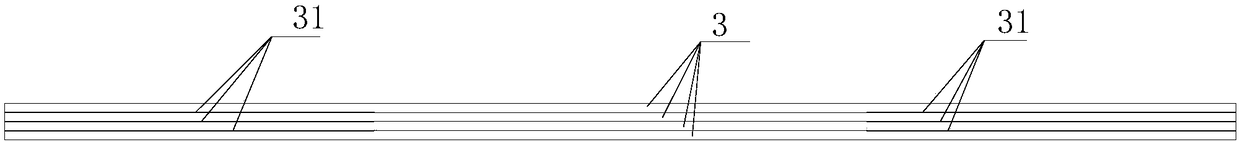

[0040] like figure 1 and figure 2 As shown, an energy-saving and heat-retaining inner pot in this embodiment includes an inner pot body 1 and a layer of foam layer 2 integrally connected to the outer surface of the inner pot body 1 . The thickness of the foam layer 2 is 1mm-2mm, which can be selected as 1.2mm, 1.4mm, 1.6mm and 1.8mm; , 3mm, 3.5mm, 4mm and 4.5mm. The thickness of the thermal insulation inner pot of the present embodiment is uniform. The foam layer 2 in this embodiment is mainly made of metal hydride, such as titanium hydride. The inner pot body 1 of this embodiment can be made of aluminum, iron or stainless steel. By setting a layer of foam layer 2 on the outer surface of the inner pot body 1, the inner pot has the advantages of heat preservation, energy saving, strong impact resistance, light weight and portability. By reasonably limiting the distance between the foam layer and the bottom of the inner pot body, the foam layer is prevented from decomposin...

Embodiment approach 1

[0042] Embodiment 1, such as figure 1 As shown, the inner pot body 1 is made of magnetically conductive material, and the foam layer 2 covers the outer surface of the entire inner pot body 1 . In this embodiment, by making the foam layer cover the outer surface of the entire inner pot body, the heat preservation effect is good, and it is suitable for IH heating.

Embodiment approach 2

[0043] Embodiment 2, such as figure 2 As shown, the inner pot body 1 includes a bottom wall 12 and a side wall 11 integrally connected to the peripheral edge of the bottom wall 12 , and the foam layer 2 covers the outer surface of the side wall 11 . The vertical distance between the end of the foam layer 2 close to the bottom wall 12 and the bottom wall 12 is 10mm-40mm, and can be 15mm, 20mm, 25mm, 30mm and 35mm. In this embodiment, the outer surface of the side wall of the inner pot body is covered by the foam layer, which has a good heat preservation effect and is suitable for heating with resistance wires.

[0044] In this embodiment, the thermal resistance, heat preservation time and impact resistance of the energy-saving and heat-preserving inner pot compared with the inner pot without the foam layer 2 are tested, and the test results are as follows.

[0045] Table 1 Thermal resistance of different inner pots

[0046] inner pot

In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com