Automatic assembling robot for assembly line production

An automatic assembly and assembly line technology, applied in the field of parts clamping, can solve the problems of easy slipping of the lampshade, time-consuming and labor-intensive LED lights, etc., and achieve the effect of avoiding the fragmentation of the lampshade, preventing objects from slipping, and increasing the clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

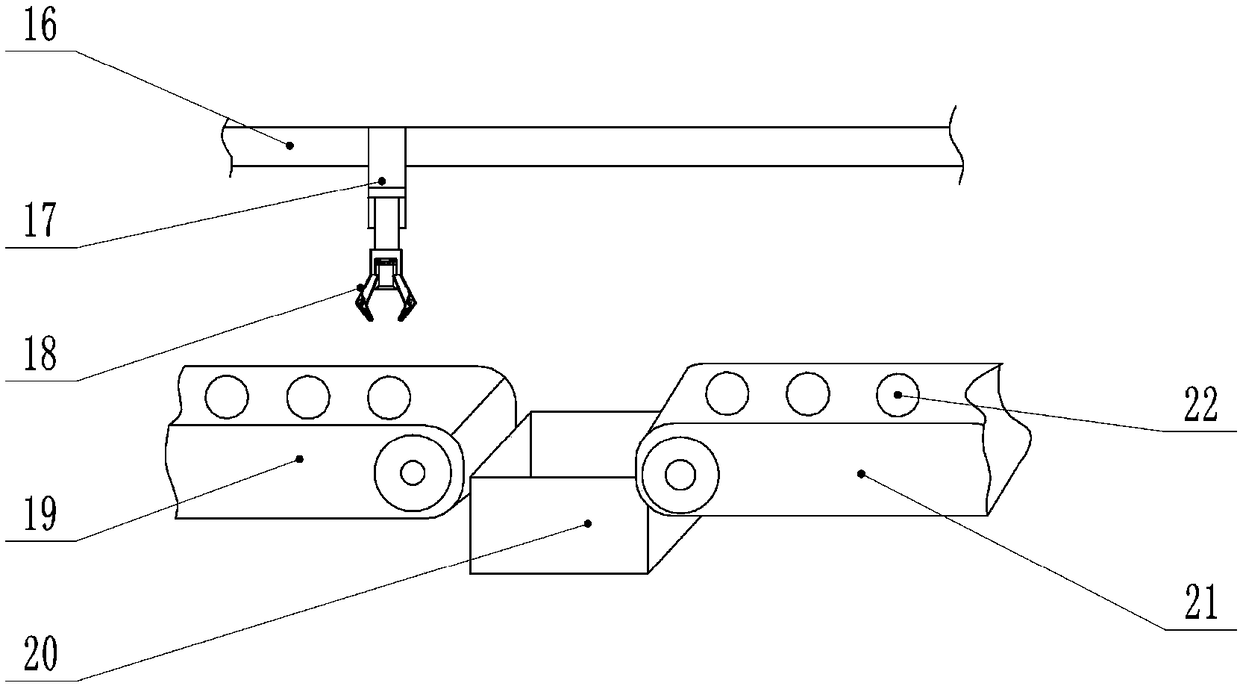

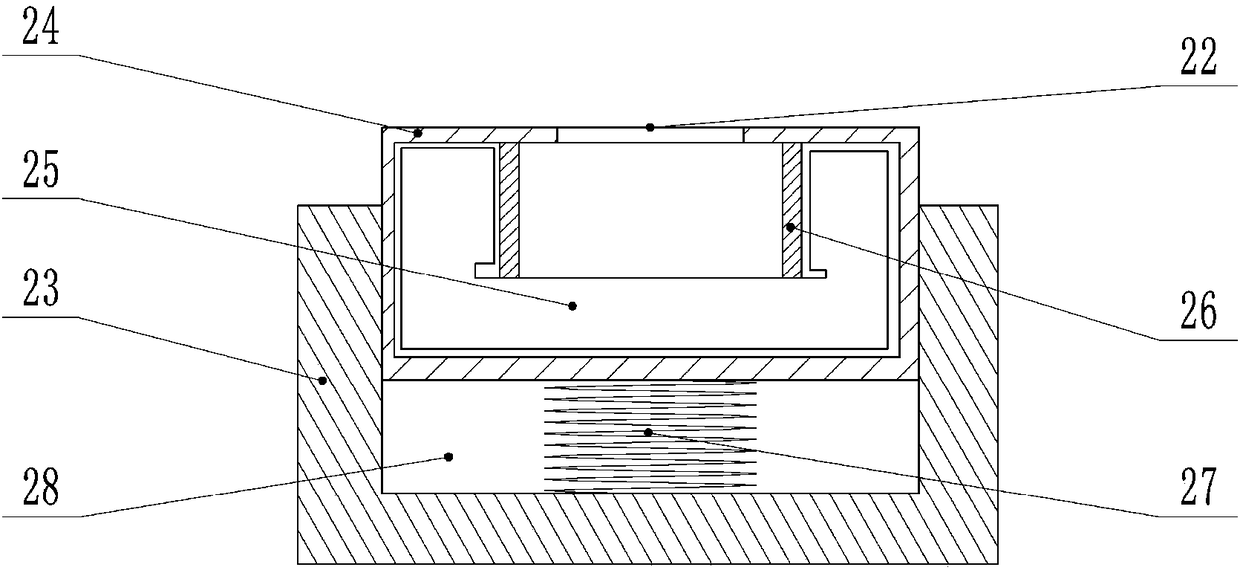

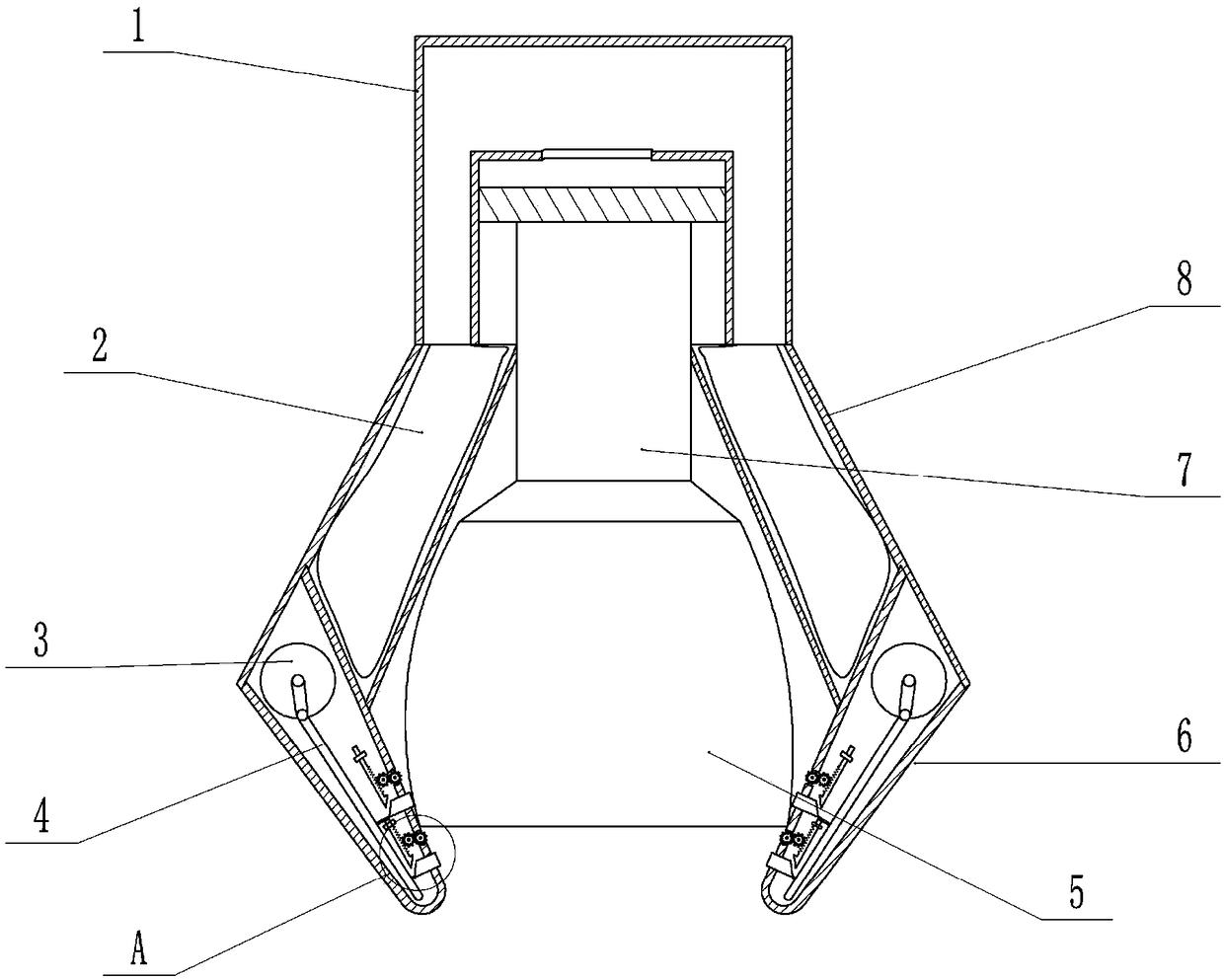

[0032] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 As shown, the automatic assembly robot used for assembly line production includes a placement frame 20 and a control module. The left side of the placement frame 20 is provided with a first transmission mechanism 19 with a transmission direction to the right, and the right side of the placement frame 20 is provided with a first transmission mechanism 19 with a transmission direction to the left. The second transmission mechanism 21, the first transmission mechanism 19 is used to transmit the lamp holder, the second transmission mechanism 21 is used to transmit the lampshade. The screw thread is connected to the threaded port; a slide rail 16 is arranged above the first transmission mechanism 19 and the second transmission mechanism 21, and the slide rail 16, the first transmission mechanism 19 and the second transmission mechanism 21 are arranged in parallel, and the slide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com