Crank shaft lathe center frame device

A crankshaft lathe and center rest technology, applied in auxiliary devices, turning equipment, turning equipment, etc., can solve the problems of low quality, unstable crankshaft rotation and processing, crankshaft deviation, etc., to improve quality and efficiency, and ensure stability. , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

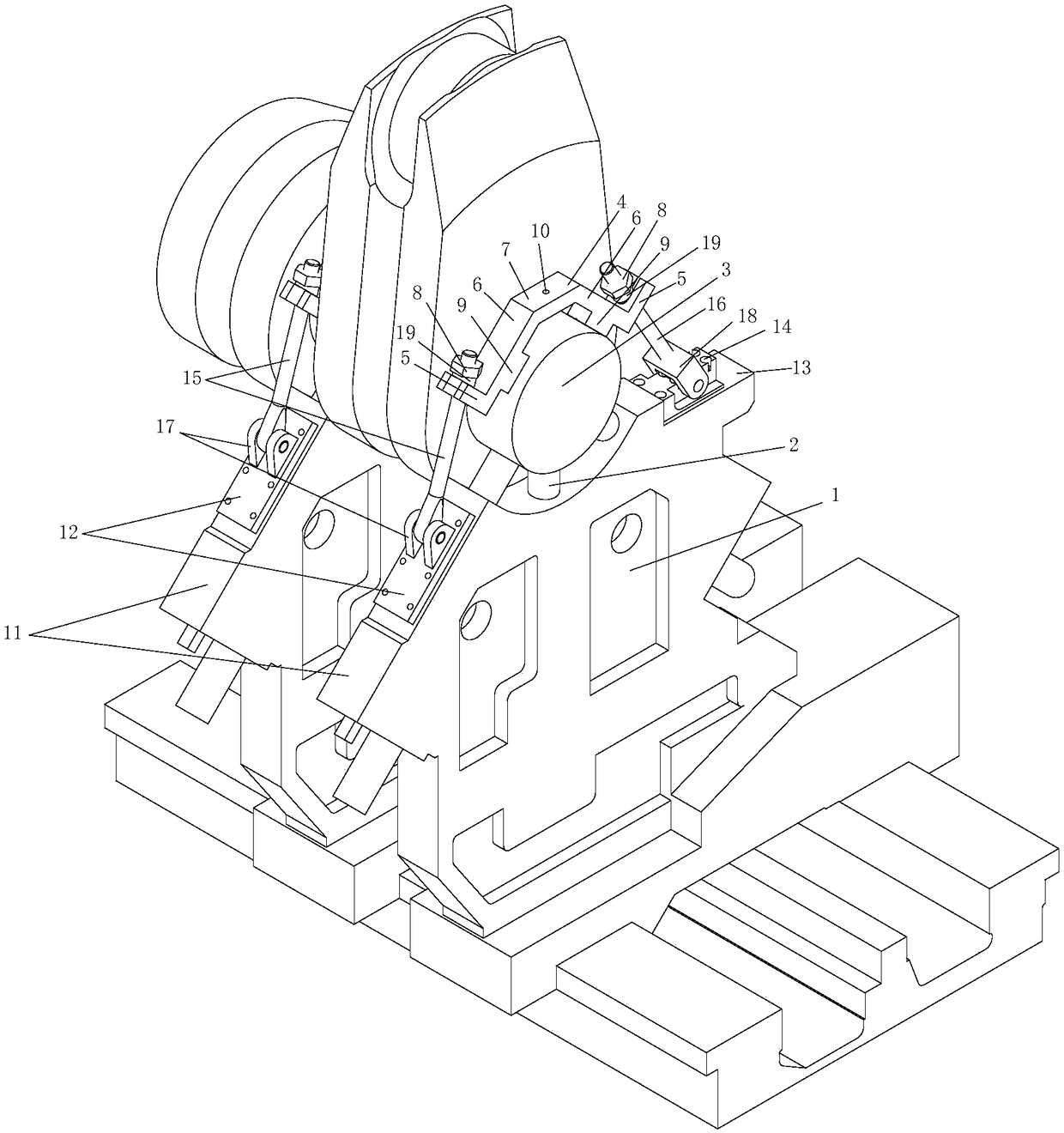

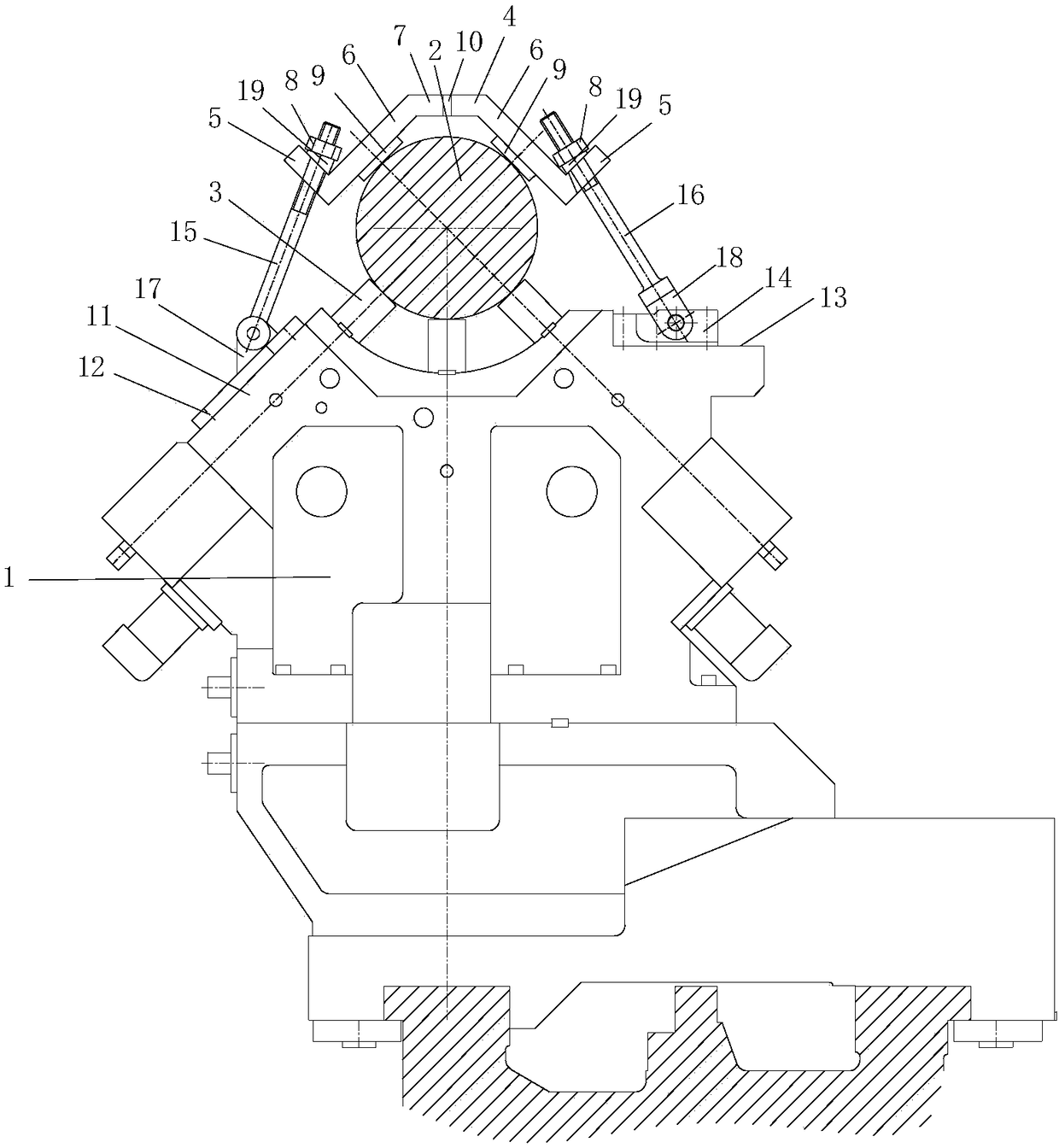

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

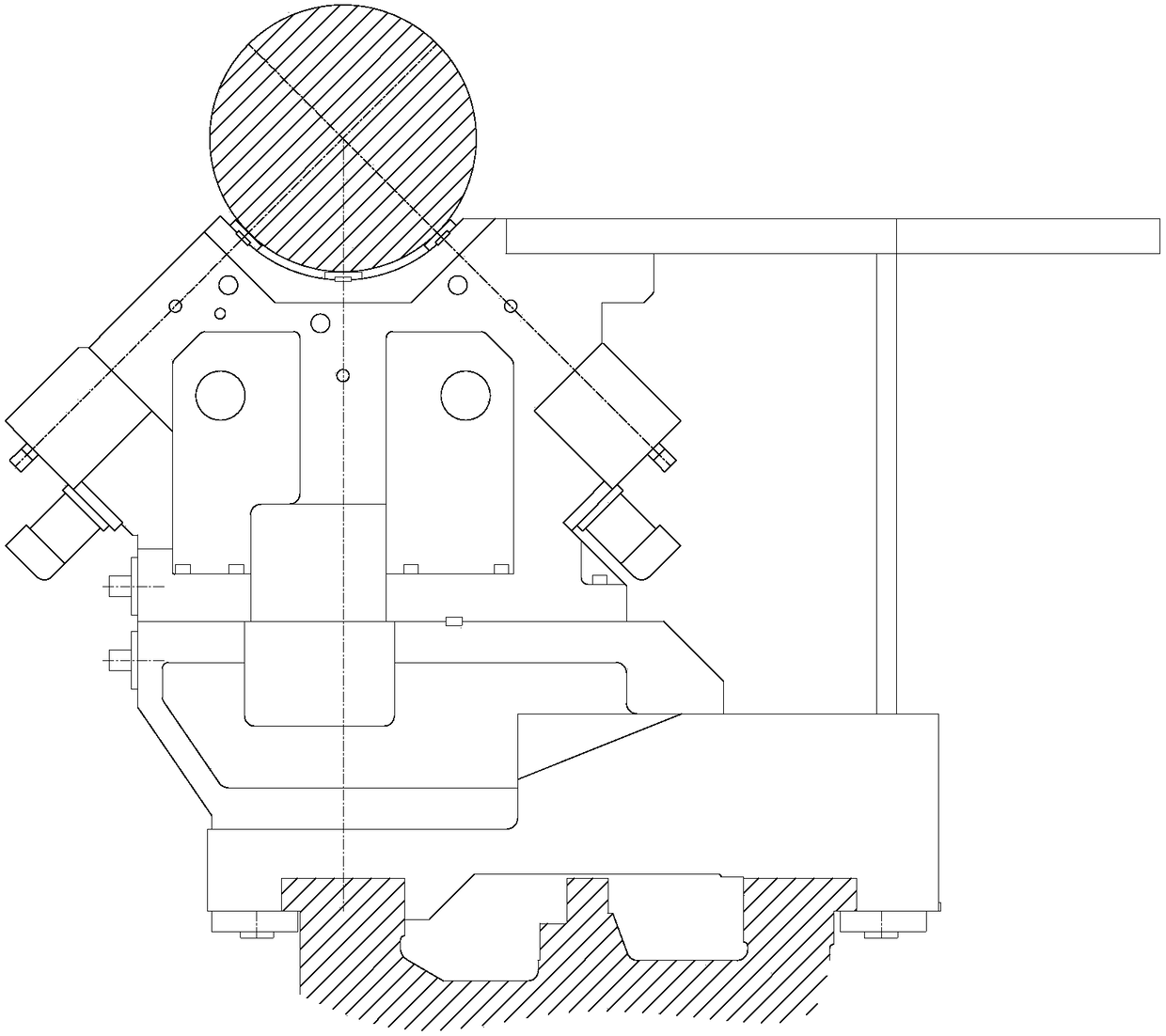

[0023] combine figure 2 with image 3 , a crankshaft lathe center frame device, including a center frame 1, in the middle of the center frame 1 is provided with three support columns 3 for supporting the main journal 2 of the crankshaft.

[0024] Two of the supporting columns are respectively arranged at a 45-degree inclination in the middle of the center frame, and the other supporting column is arranged in the center of the middle of the center frame, and the supporting column provides lower support for the main journal.

[0025] The center frame 1 is provided with a cover structure that can be stably pressed on the upper part of the main journal, and the cover structure provides upper stabilizing force for the main journal.

[0026] The cover plate structure includes a pressing plate 4, and both sides of the pressing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com