Automobile transmission shaft tube automatic grinding device

A technology for transmission shaft tubes and automobiles, which is applied in the direction of grinding drive devices, grinding machines, grinding/polishing equipment, etc., which can solve the problems of high labor costs and low manual grinding efficiency, and achieve improved quality, improved grinding efficiency, and constant improvement sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is further described in detail through specific implementation methods:

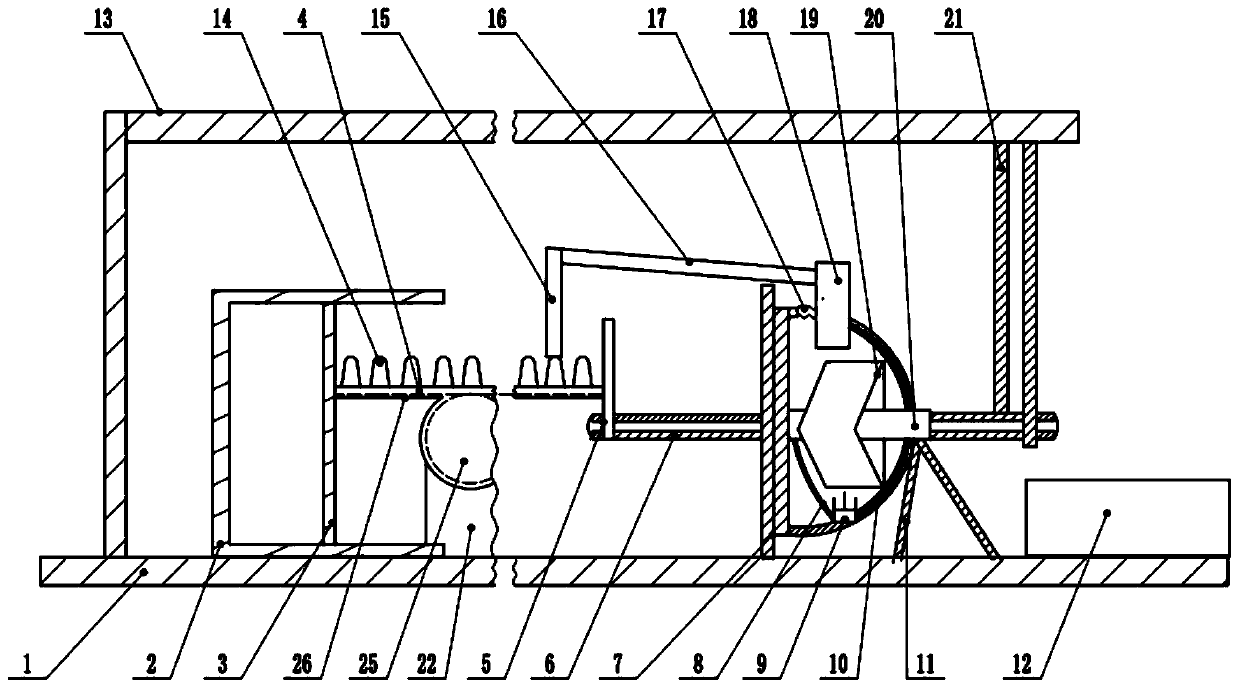

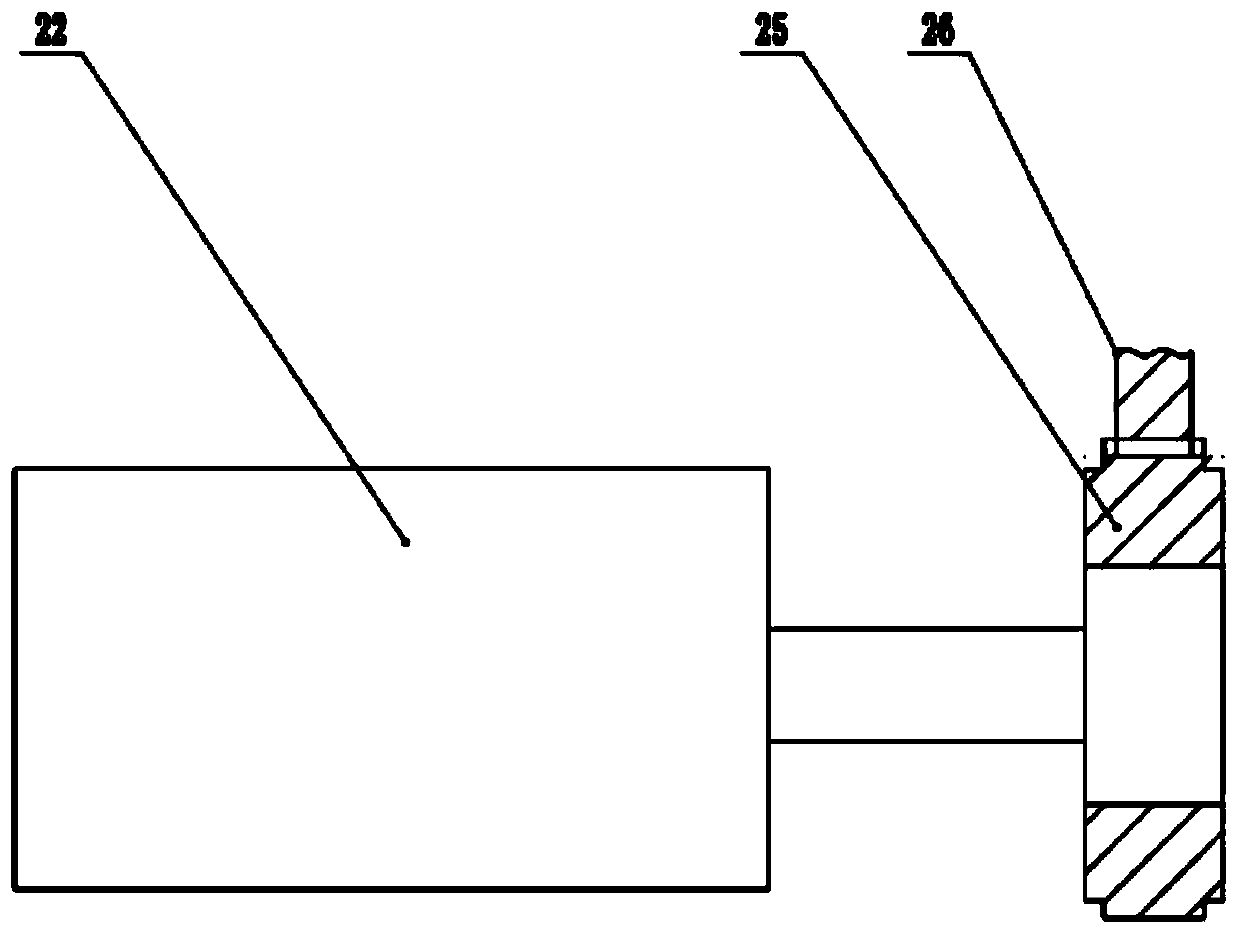

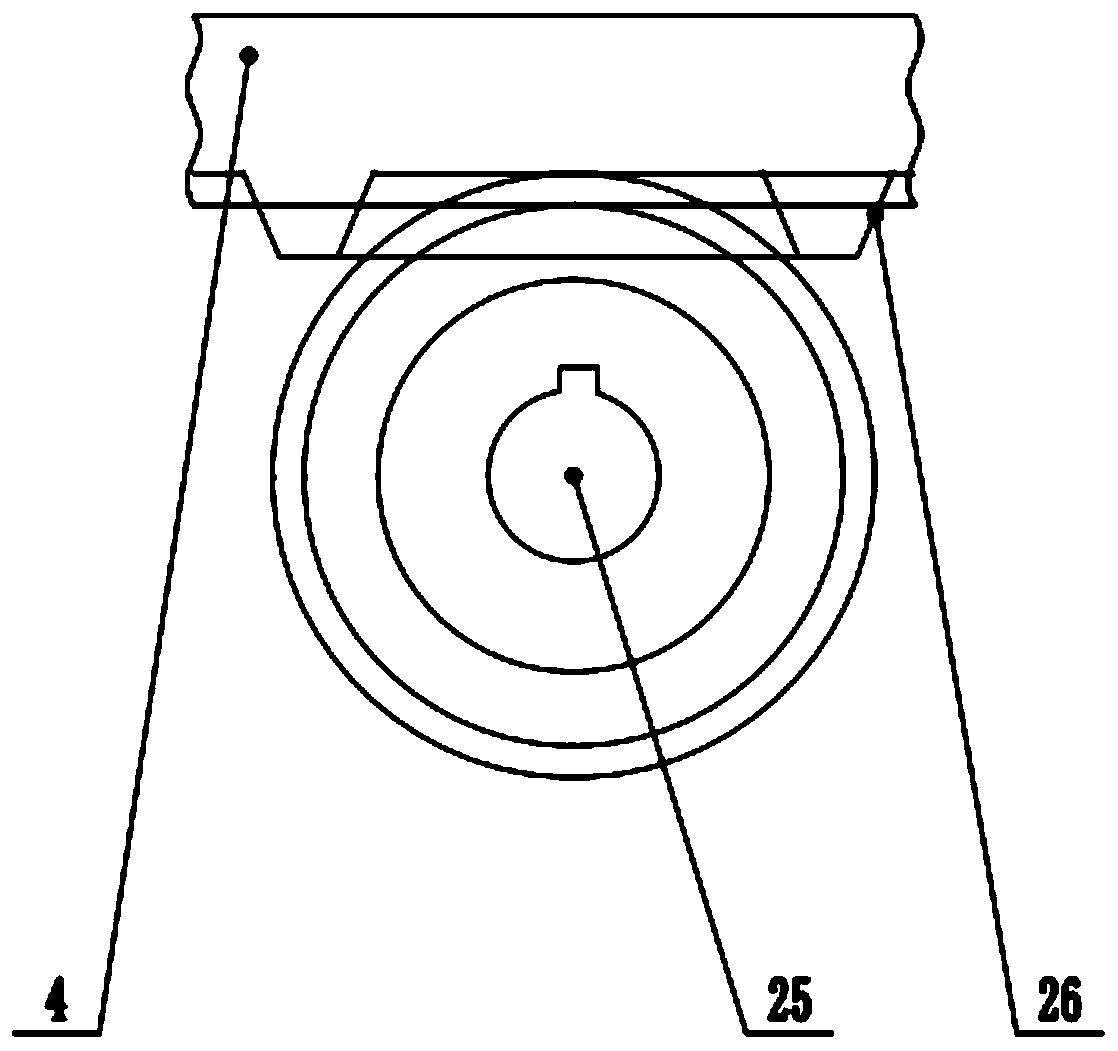

[0038] The reference signs in the drawings of the description include: workbench 1, first cylinder 2, first push plate 3, first piston rod 4, feeding plate 5, circular groove feeding groove 6, oval shell 7, chip suction duct 8 , second cylinder 9, exhaust duct 10, support rod 11, collection frame 12, support 13, translation cam group 14, vertical power rod 15, lateral power rod 16, torsion spring 17, electromagnet 18, triangular inner ring rotor 19. Grinding barrel 20 , fixed arm 21 , stepping motor 22 , second push plate 23 , second piston rod 24 , rotating gear 25 , and driving gear 26 .

[0039] The embodiment is basically as attached figure 1 Shown: the automatic grinding device for the transmission shaft tube of an automobile comprises a workbench 1, a fixed arm 21, a support rod 11, a stepper motor 22, a feeding plate 5, a circular groove feeding groove 6 and a push plate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com