Dressing device and method for a symmetrical double-cone grinding wheel

A dressing device and double-cone technology, which is applied in the direction of abrasive surface adjustment devices, grinding machine parts, metal processing equipment, etc., can solve the problems affecting the dressing accuracy of grinding wheels, limited working space, difficult layout, etc., and achieve simple structure, The cone angle can be adjusted arbitrarily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

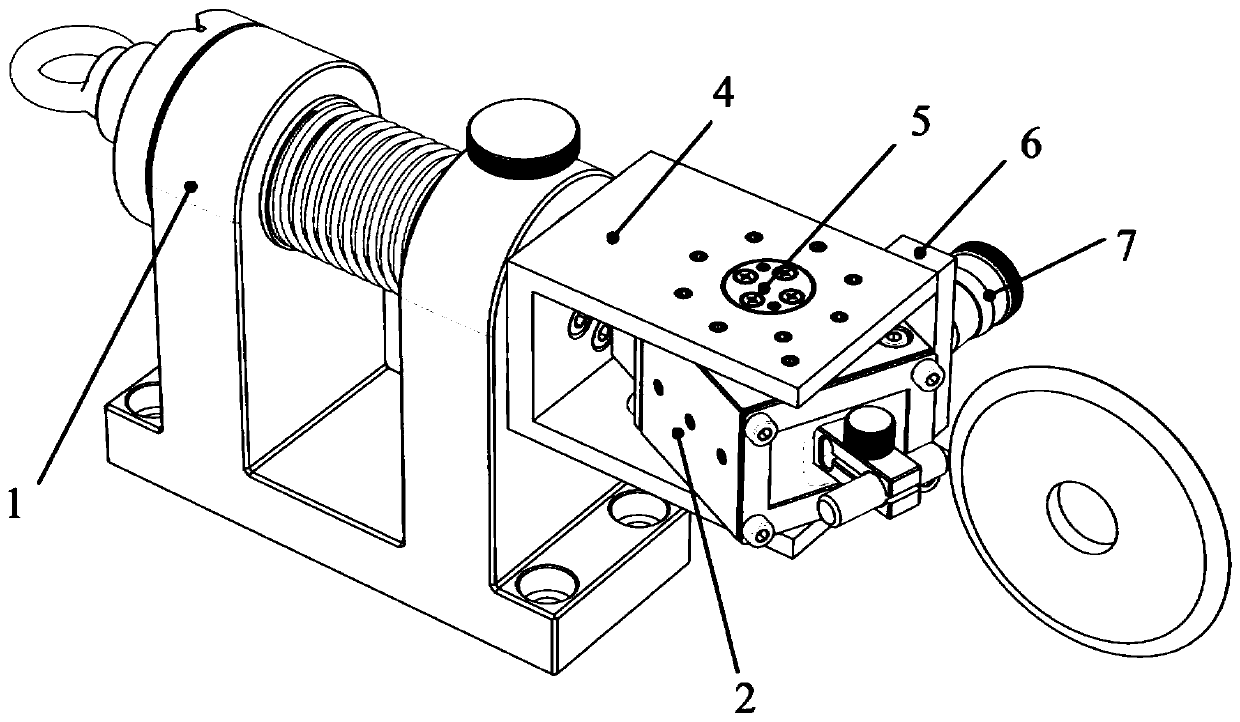

[0022] Utilizing the solution and device structure provided by the published invention patent "a diamond pen grinding wheel dresser (CN107471114A)" and "a high-precision 180° flip positioning device and its installation method (CN107825377A)", a symmetrical double A dressing method and a dressing device for a conical grinding wheel.

[0023] (1) Precision assembly

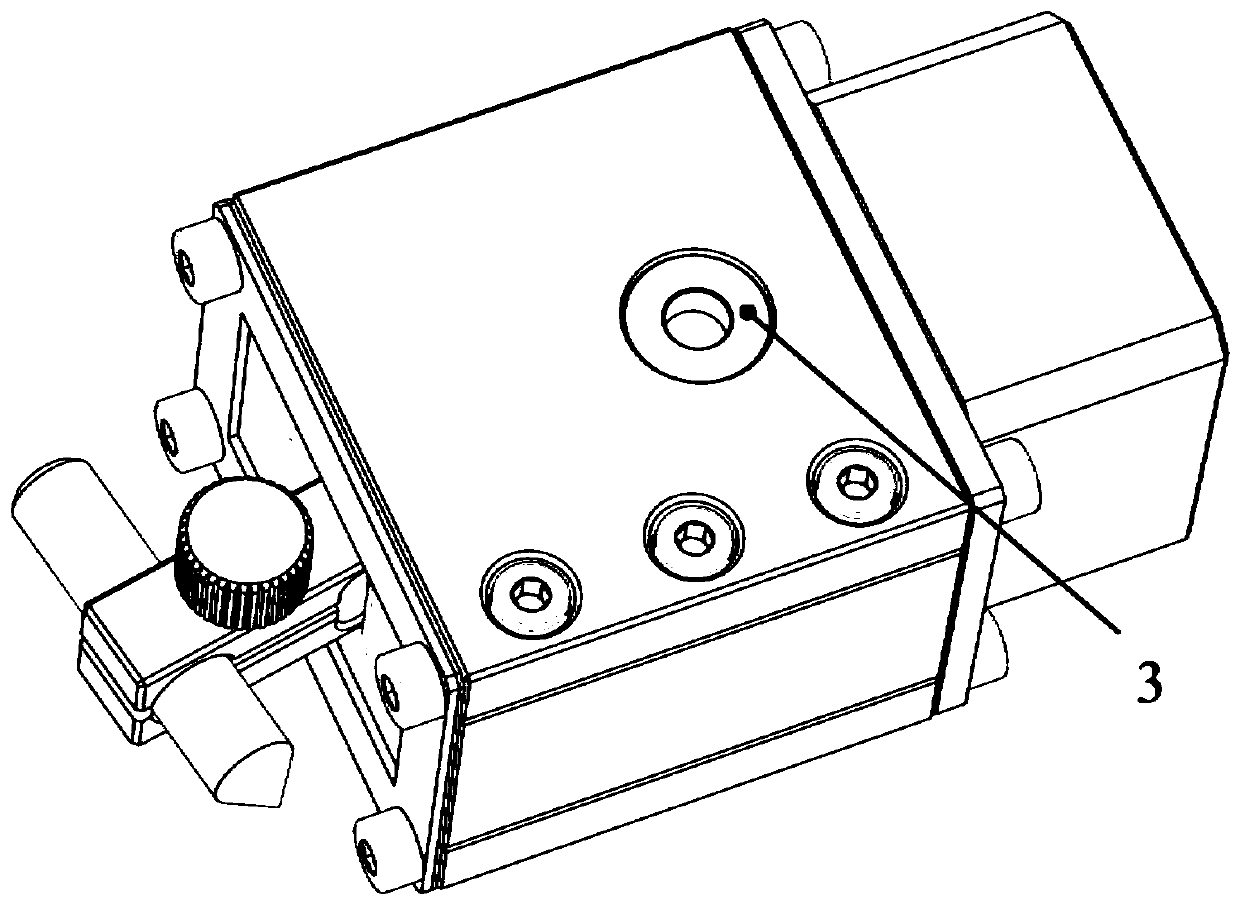

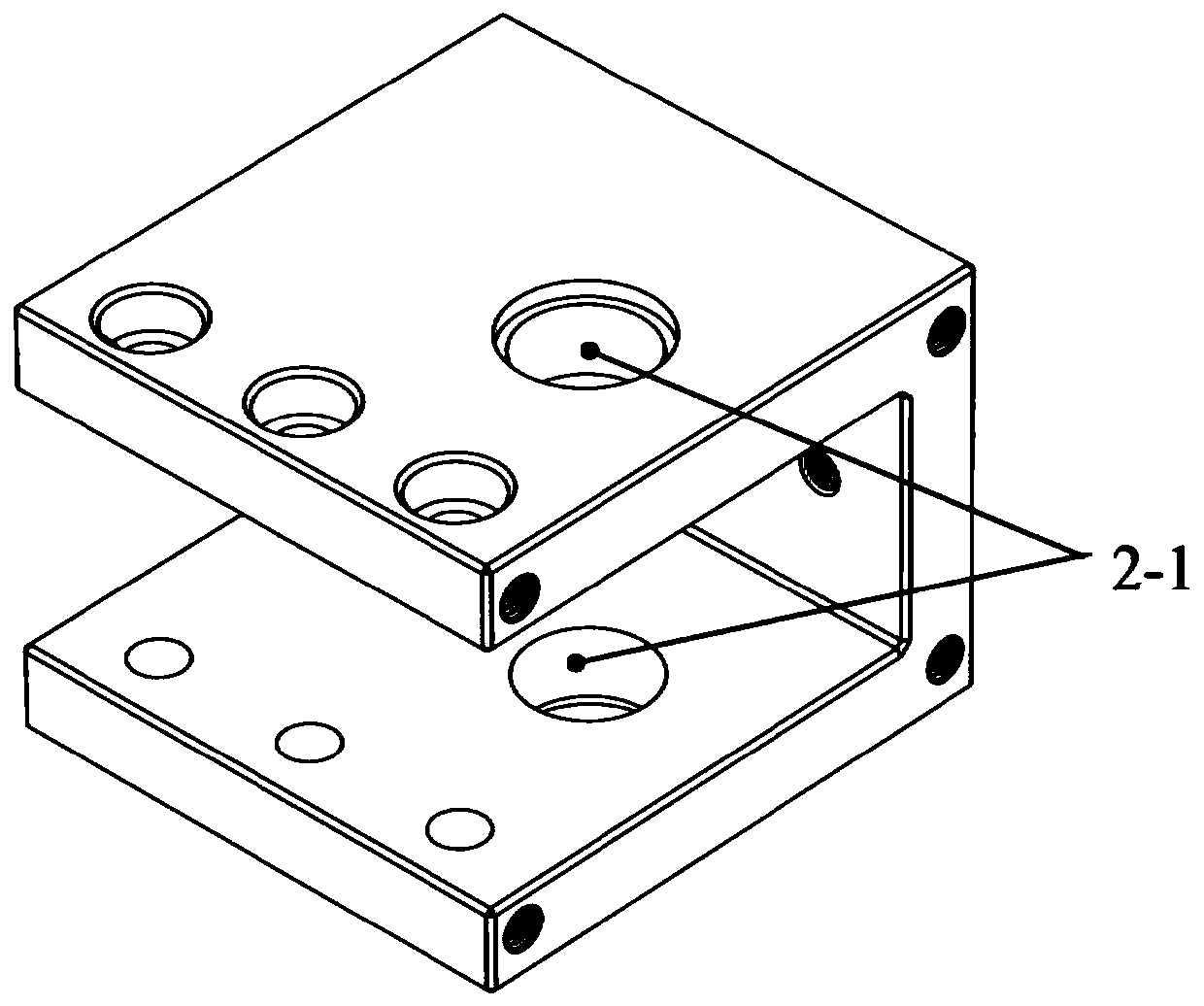

[0024] First, process two symmetrical countersunk holes A2-1 on the housing of the diamond pen dresser 2, the axes of the two countersunk holes A2-1 are consistent and perpendicular to the movement direction of the diamond pen dresser 2; The countersunk depth of A2-1 is slightly greater than the thickness of the flange of the flange bearing 3; the countersunk diameter of the countersunk hole A2-1 is slightly greater than the maximum diameter of the flange bearing 3; the flange bearing 3 is pressed into the diamond through interference fit In the counterbore A2-1 on the housing of the pen trimmer 2.

[0025] Then,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com