Three-layer intelligent PUR (Polyurethane) hot melt adhesive foaming wrinkled fabric

A hot-melt adhesive and fabric technology, applied in the field of textile and clothing, can solve the problems of different shrinkage of wrinkled fabrics, affecting the forming effect of wrinkled fabrics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

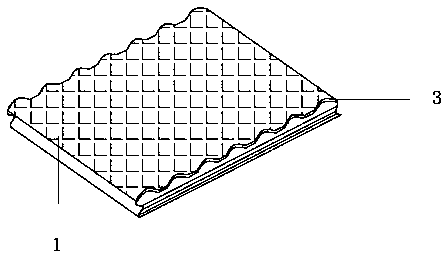

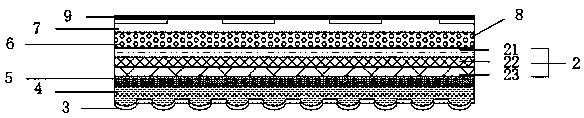

[0017] like Figure 1-2 As shown, a three-layer intelligent PUR hot-melt adhesive foaming wrinkle fabric includes a fabric body 1 and a knitted woven layer 2, a base fabric 4 is provided under the fabric body 1, and a skin-friendly layer 3 is connected to the bottom of the base fabric 4 , the side of the base fabric 4 away from the skin-friendly layer 3 is connected with a PUR hot melt adhesive 5, and the side of the PUR hot melt adhesive 5 away from the base fabric 4 is connected with a knitted weaving layer 2, and the knitted weaving layer 2 is provided with Chemical fiber layer 21, cotton layer 22 and linen layer 23, the bottom of the knitted woven layer 2 is provided with a linen layer 23, the side of the linen layer 23 away from the PUR hot melt adhesive 5 is connected to the cotton layer 22, and the cotton layer 22 is far away from the linen layer 23 One side of the knitted fabric layer 2 is connected to the chemical fiber layer 21, and the side of the knitted woven laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com