Wide-span girder main beam structure, combined formwork system and construction method for cable-stayed bridge

A technology for combined formwork and cable-stayed bridges, which is applied in the direction of cable-stayed bridges, bridges, bridge forms, etc., and can solve the problem of difficult removal of steel formwork side forms for temporary placement, difficulty in joints at chamfers of beam lattices, and inability to guarantee the quality of concrete, etc. problems, to achieve the effect of safe and fast installation and dismantling operations, guarantee the overall construction quality, and control the internal quality and appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

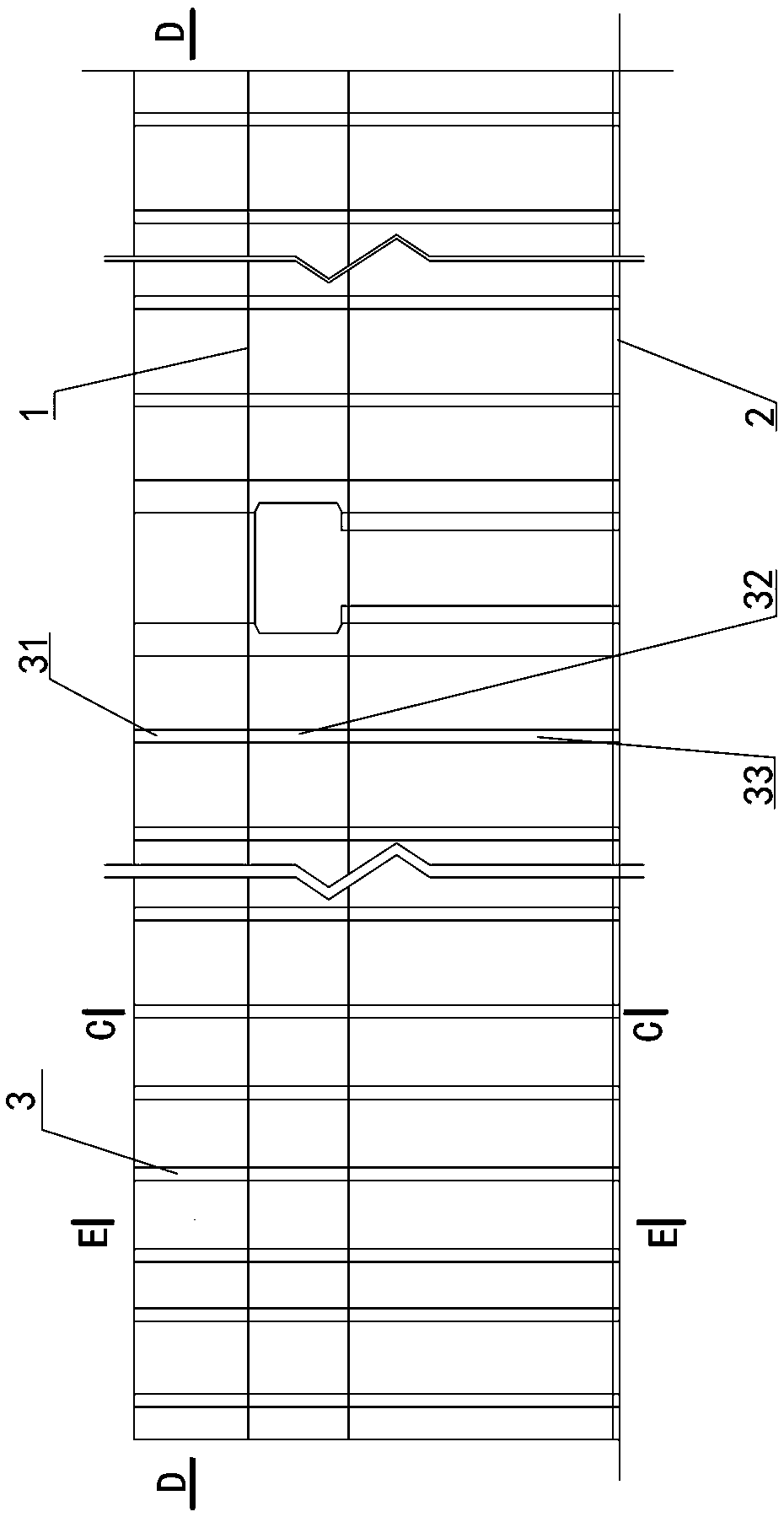

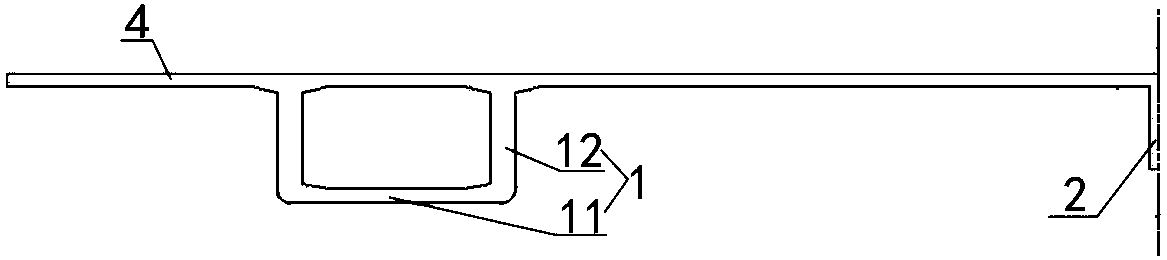

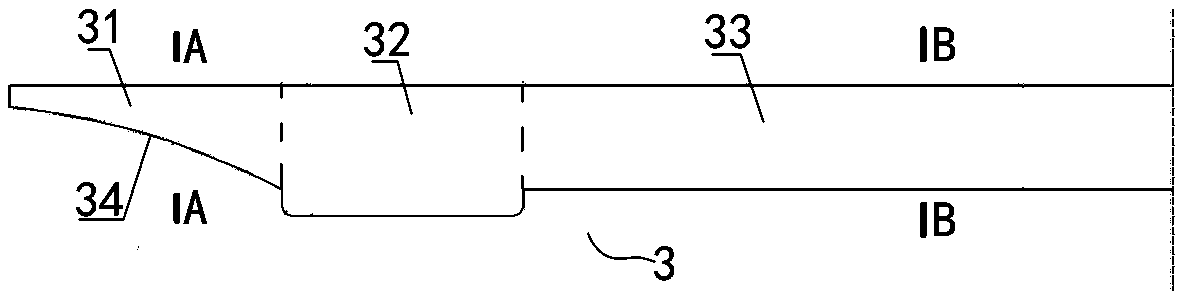

[0054] Examples see Figure 1-5 As shown, a cable-stayed bridge is a concrete cable-stayed bridge with three spans, two towers and two cable planes, with a bridge width of 48m. The main girder structure is a wide-width beam lattice concrete main girder structure, including the lower longitudinal girders along the bridge and the transverse beams of the transverse bridge, and the upper bridge deck 4 . The longitudinal girders include two main longitudinal girders 1 symmetrically arranged along the transverse bridge direction and a secondary longitudinal girder 2 located on the central axis of the bridge deck, and a group of transverse girders 3 are arranged at intervals along the bridge direction, and the longitudinal girders and The beams are connected under the deck to form a lattice. In this embodiment, there are 68 beams in the direction of the bridge, which together form 268 beam grids.

[0055] see figure 2 As shown, the main longitudinal girder is a single box girder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com