High-ductility prestressed fabricated concrete beam-column connecting joint and construction method thereof

A beam-column connection and prestressing technology, which is applied in the direction of construction and building construction, can solve the problems of poor ability of dry connection to transmit beam end bending moment, complex joint connection form, and unreliable quality assurance, etc., to achieve rapid construction, Good resistance to progressive collapse and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention are now described in detail.

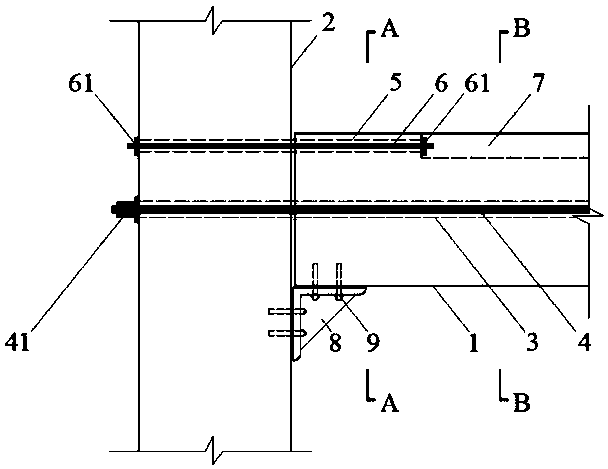

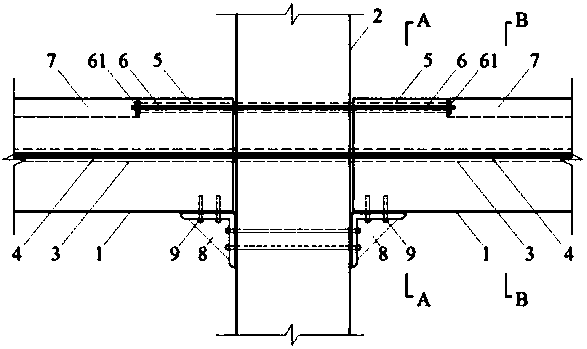

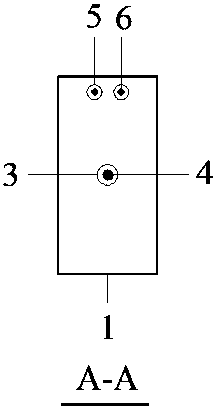

[0035] Such as figure 1 and figure 2 As shown, the cross-sectional size, reinforcement, concrete strength grade, etc. of prefabricated reinforced concrete or prefabricated prestressed concrete beam 1 and column 2 are determined according to the design. During prefabrication, the groove 7 is preset on the beam through the formwork, and the pre-embedded bellows or steel pipes are used to reserve the channels 3 and 5; To ensure that the prestressed tendons can pass through the core area of the prefabricated column, the position of the channel in the column and the channel in the beam should be exactly the same. According to the design drawings, high-strength connecting bolts 9 are pre-embedded at specified positions in the beam and column. In order to ensure the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com