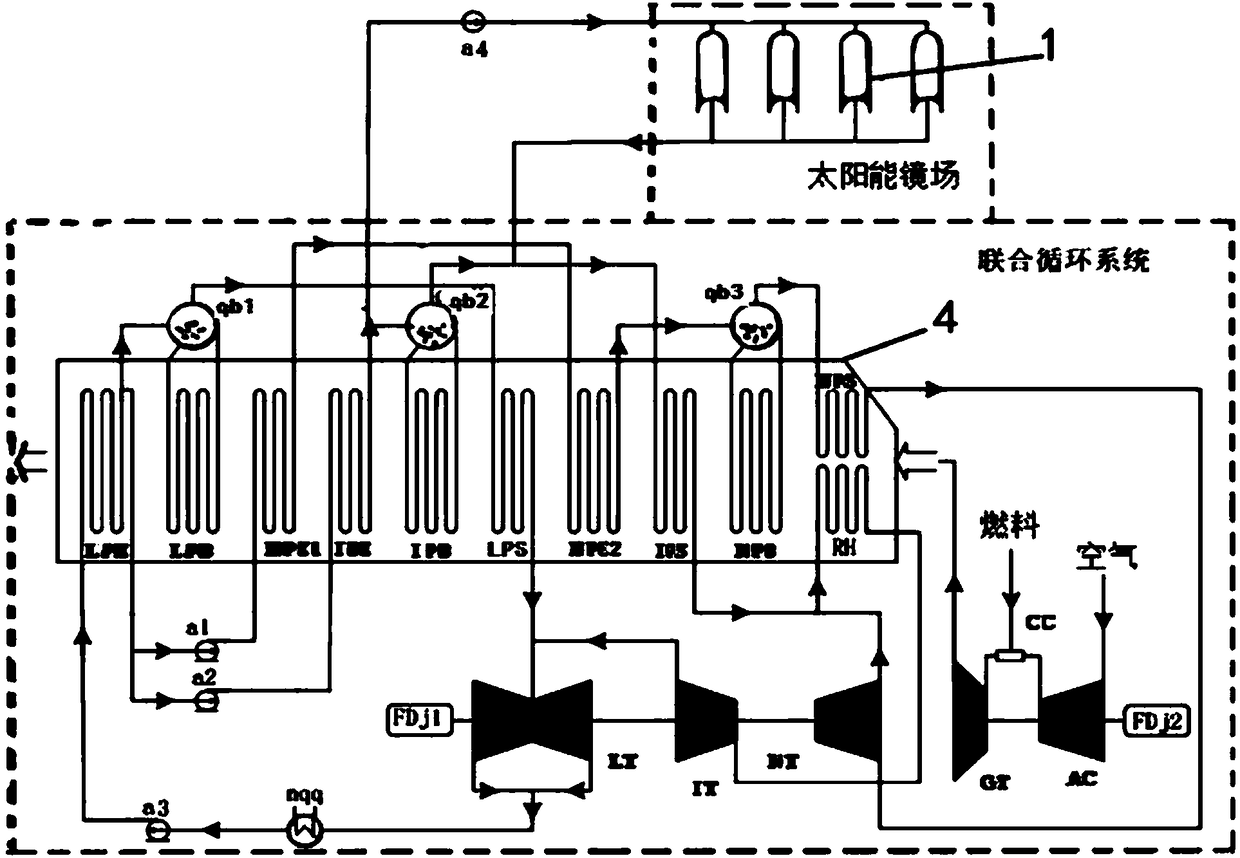

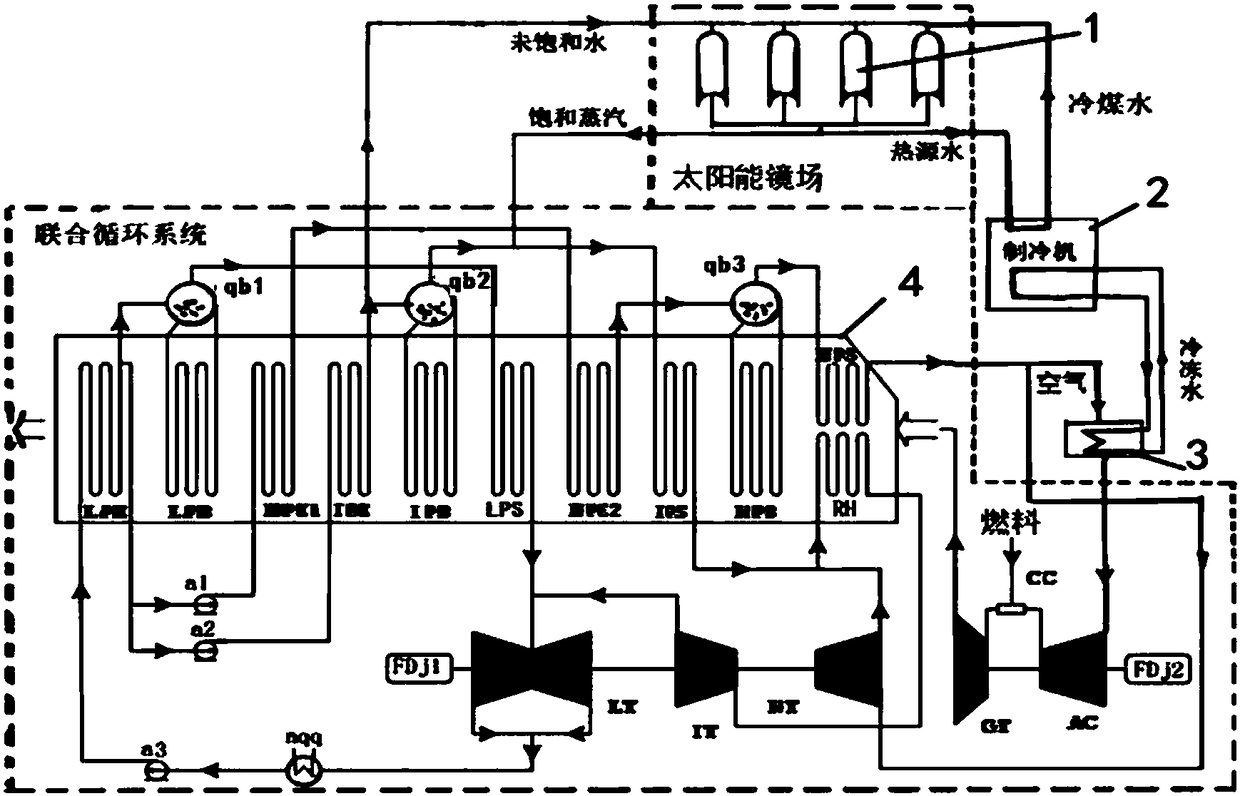

Cold and heat combined solar heat complementation combined cycle integrated system

A technology of solar thermal and combined cycle, which is applied in the directions of solar thermal power generation, mechanical power generation by solar energy, mechanism for generating mechanical power, etc., which can solve the problems of rising compressor inlet temperature, reducing system efficiency and output, and low solar energy utilization rate, etc. problems, to achieve the effect of reducing adverse effects, increasing annual utilization rate, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Choose the meteorological data of Jiuquan, Gansu as the design conditions, calculate the thermodynamic performance of the two systems at the summer solstice design point and the whole year, and explain the effect of the present invention as follows.

[0018] In order to accurately compare the thermodynamic performance of the two systems, the solar energy production in the integrated system is defined as:

[0019]

[0020] where P ISCC — Electricity production based on new integrated solar system (ISCC), MW;

[0021] P GTCC - Electricity production based on the basic combined cycle system (GTCC), MW;

[0022] f fuel,ISCC — new system (ISCC) fuel volume, kg / s;

[0023] f fuel,GTCC - basic system (GTCC) fuel quantity, kg / s.

[0024] The photoelectric conversion rate of solar energy is:

[0025]

[0026] where Q 辐射 —The amount of solar radiation received by the solar collector mirror site, MW.

[0027] The cycle efficiency of the integrated system is:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com