Testing device for reliability of grating encoder

A technology of grating encoder and test device, which is applied to instruments and other directions, can solve the problems of low reliability of grating encoder, small number of operations, and difficulty in disassembly, so as to meet the requirements of accelerated test, reduce failure, and facilitate maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with accompanying drawing:

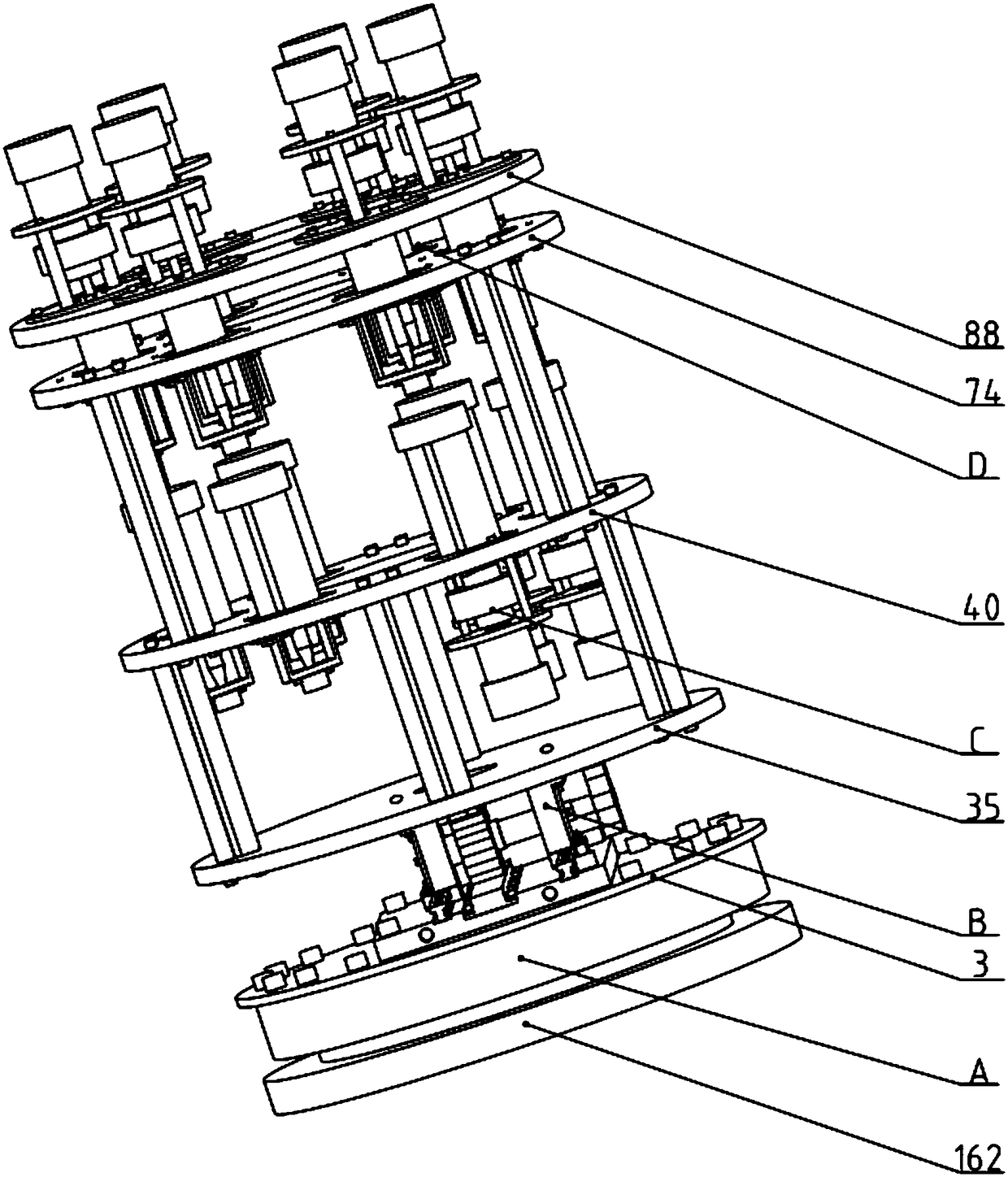

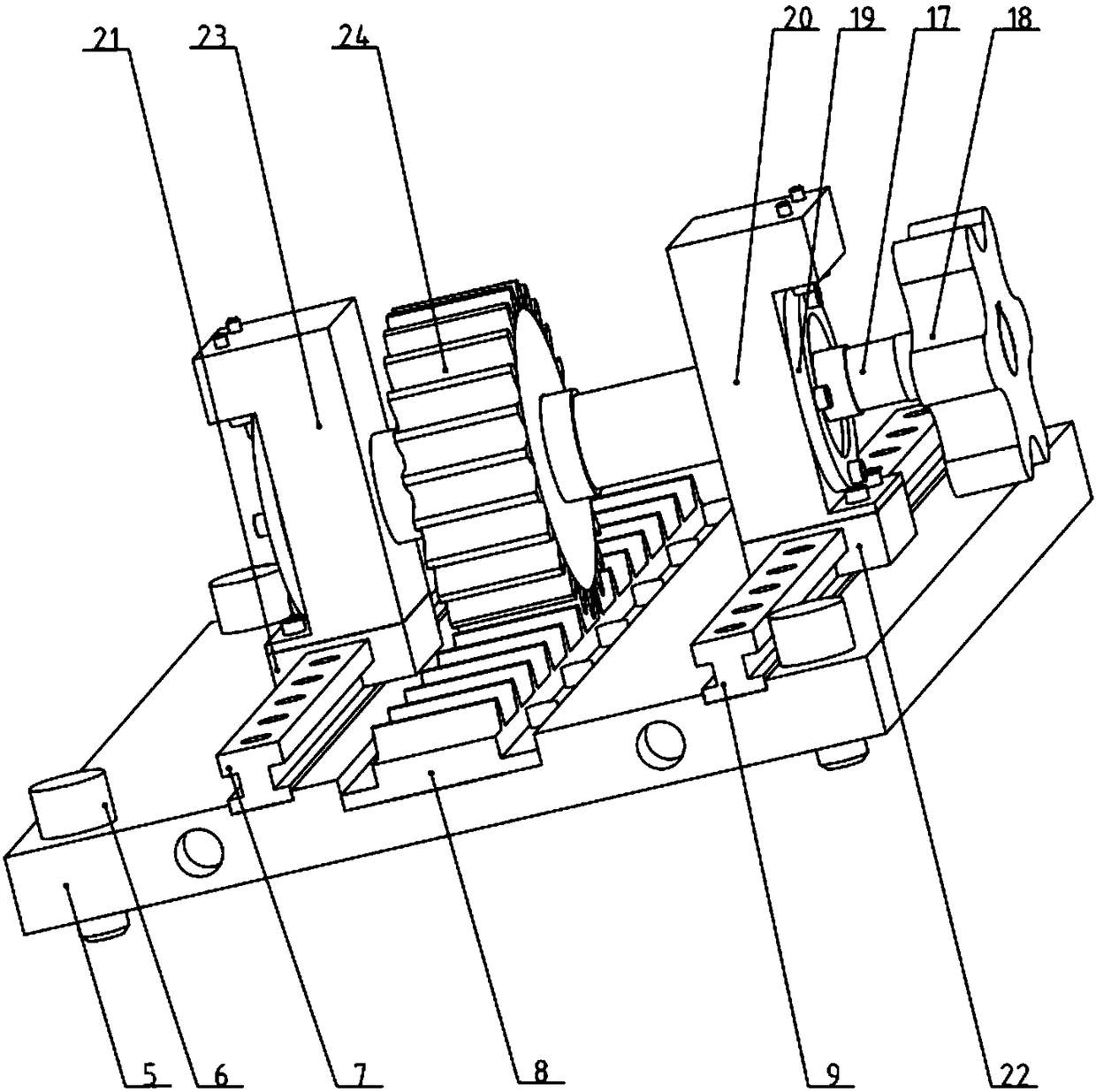

[0051] The grating encoder reliability test device of the present invention includes a main body, a high and low telescopic trolley, a simulated working condition device and a detection control system; wherein: the main body includes a rotary device A, a loading and unloading device B, and a mounting device; the mounting device includes a first The first type of installation device C, the second type of installation device D; the loading and unloading device B works together with the high and low telescopic trolley to complete the loading and unloading task.

[0052] 1. Rotary device A

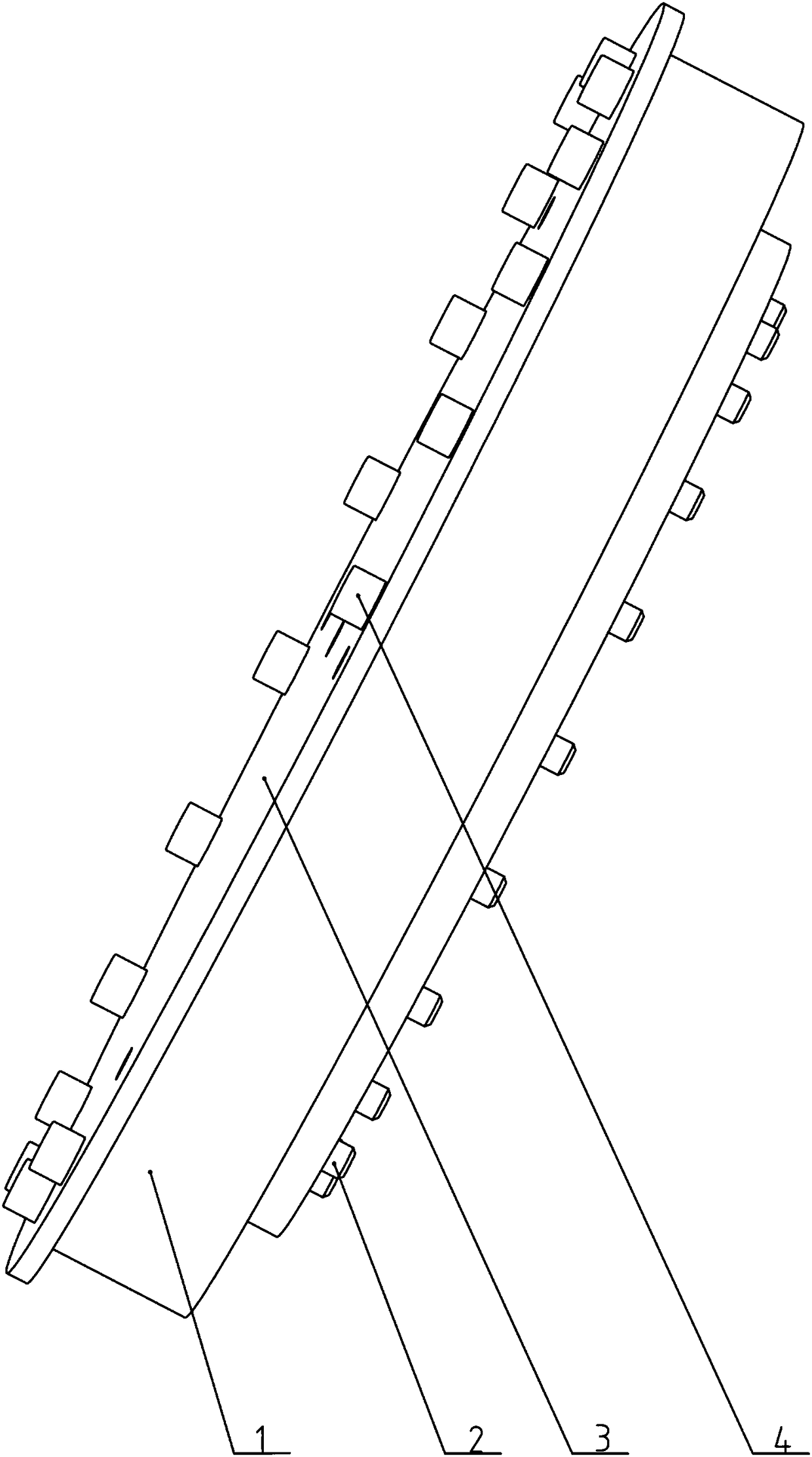

[0053] The slewing device A includes a slewing support bearing 1, a No. 1 hexagon socket head screw 2, a circular plate 3, and a No. 2 hexagon socket head screw 4;

[0054] refer to figure 2 and Figure 16 , the slewing ring bearing 1 is an axial pressure bearing, the selected slewing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com