Laser light source and control method thereof

A laser light source and laser source technology, applied in the field of light sources, can solve problems such as poor interchangeability, many optical lenses, and dark red

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

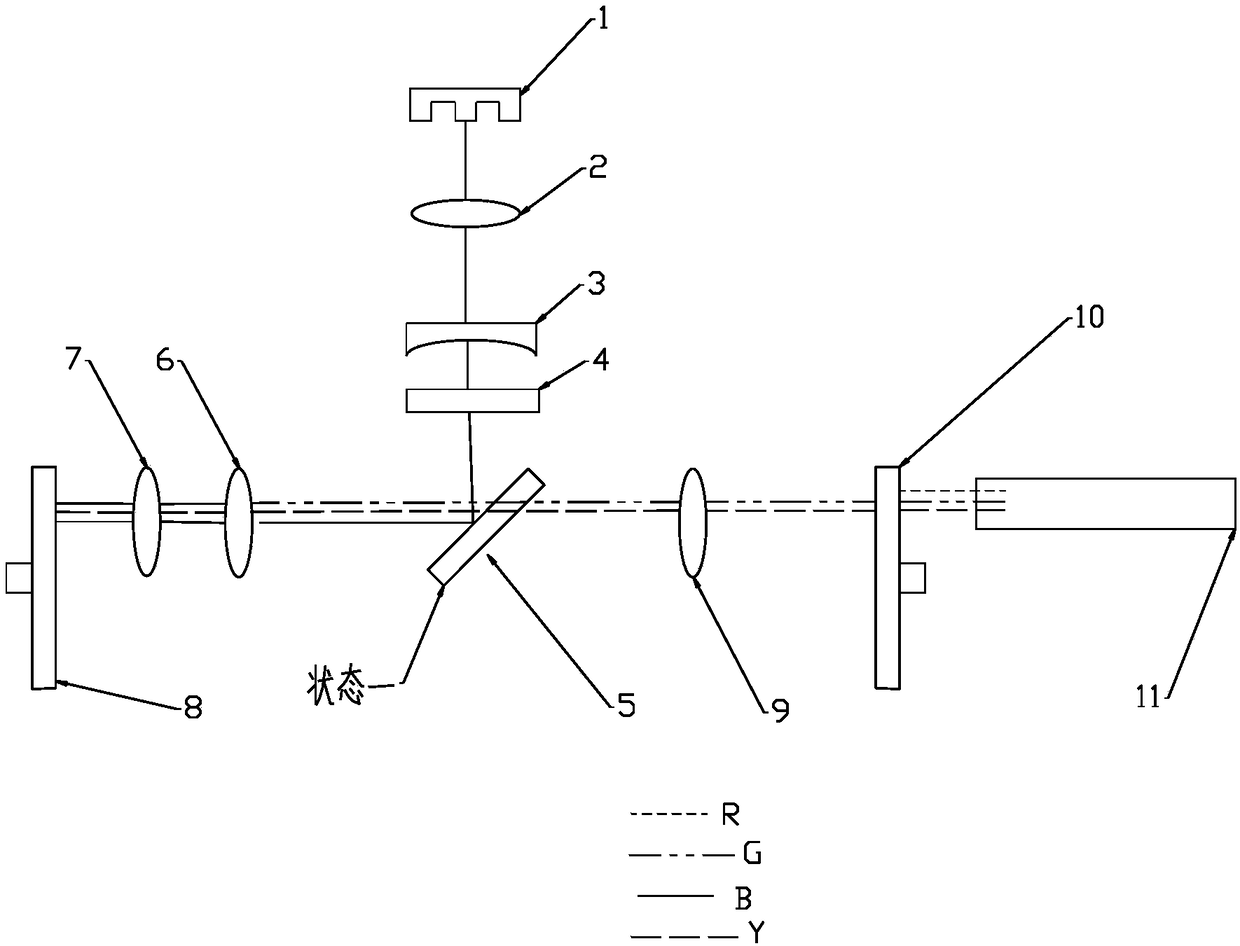

[0098] Such as figure 1 , 2 As shown, the laser light source includes: a laser source (1), a first focusing module, a first diffusing sheet (4), a first focusing module, a splitting switch element (5), a second focusing module, a diffusing unit and a light rod (11).

[0099] The laser source (1) is used to provide blue laser light.

[0100] The first light concentrating module is used for collimating and compressing the laser light emitted by the laser source (1), and projecting it onto the first diffusion sheet (4). In this embodiment, the first light concentrating module includes a collimating lens (2) and a compressing lens (3), which are respectively used for collimating light and compressing the relationship.

[0101] The first diffusion sheet (4) is used for eliminating laser speckle, and at the same time makes the light spot on the fluorescent powder wheel (8) uniform, and the fluorescence excitation efficiency is high.

[0102] The first focusing module is used for...

Embodiment 2

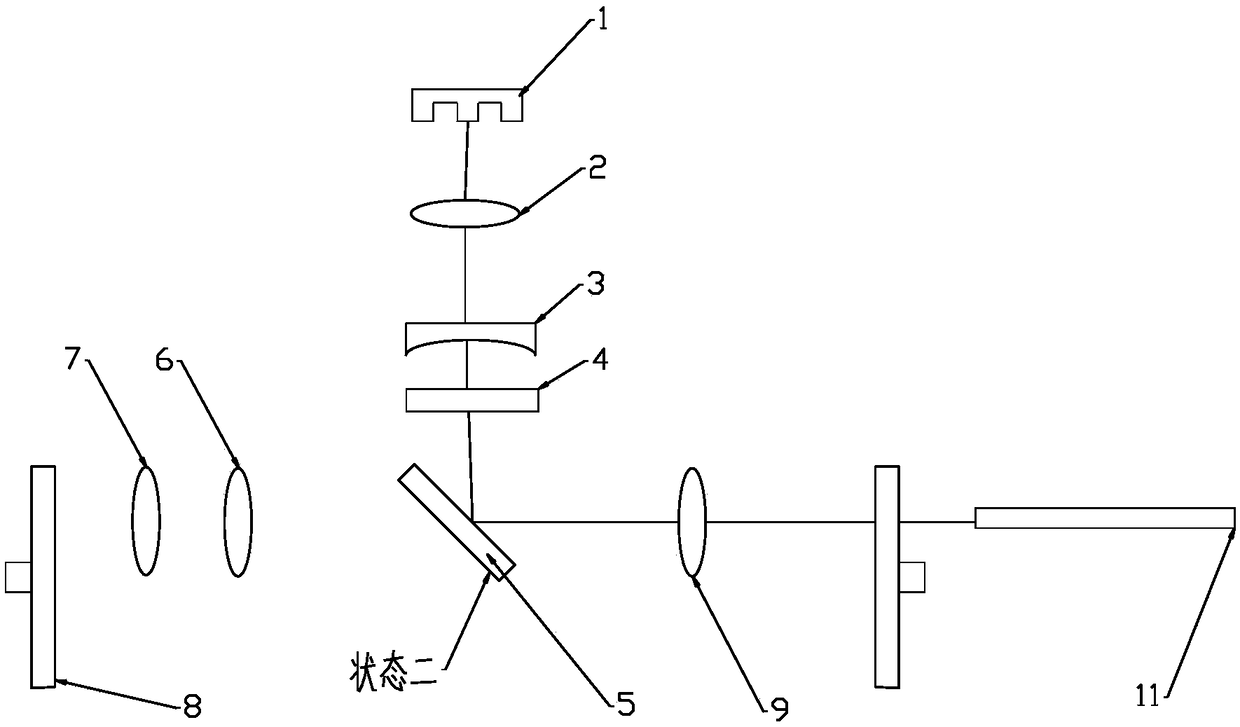

[0142] Such as image 3 , 4 As shown, embodiment two is based on embodiment one, and its difference with embodiment one is:

[0143] The laser source (1) provides red laser light in addition to blue laser light;

[0144] The light-splitting switch element (5) reflects blue laser light and red laser light, and transmits light of other colors; when the state is one, the light-splitting switch element (5) will use the light from the first diffusion sheet (4) to excite the fluorescent powder. The blue laser light is reflected to the second focusing module, the laser is focused by the second focusing module and then irradiates the phosphor wheel (8), the phosphor area on the phosphor wheel (8) excites the fluorescence of the corresponding color, and the fluorescence passes through the second focusing module focused and projected to the second focusing module through the spectroscopic switch element (5), and the fluorescent light focused by the second focusing module passes throug...

Embodiment 3

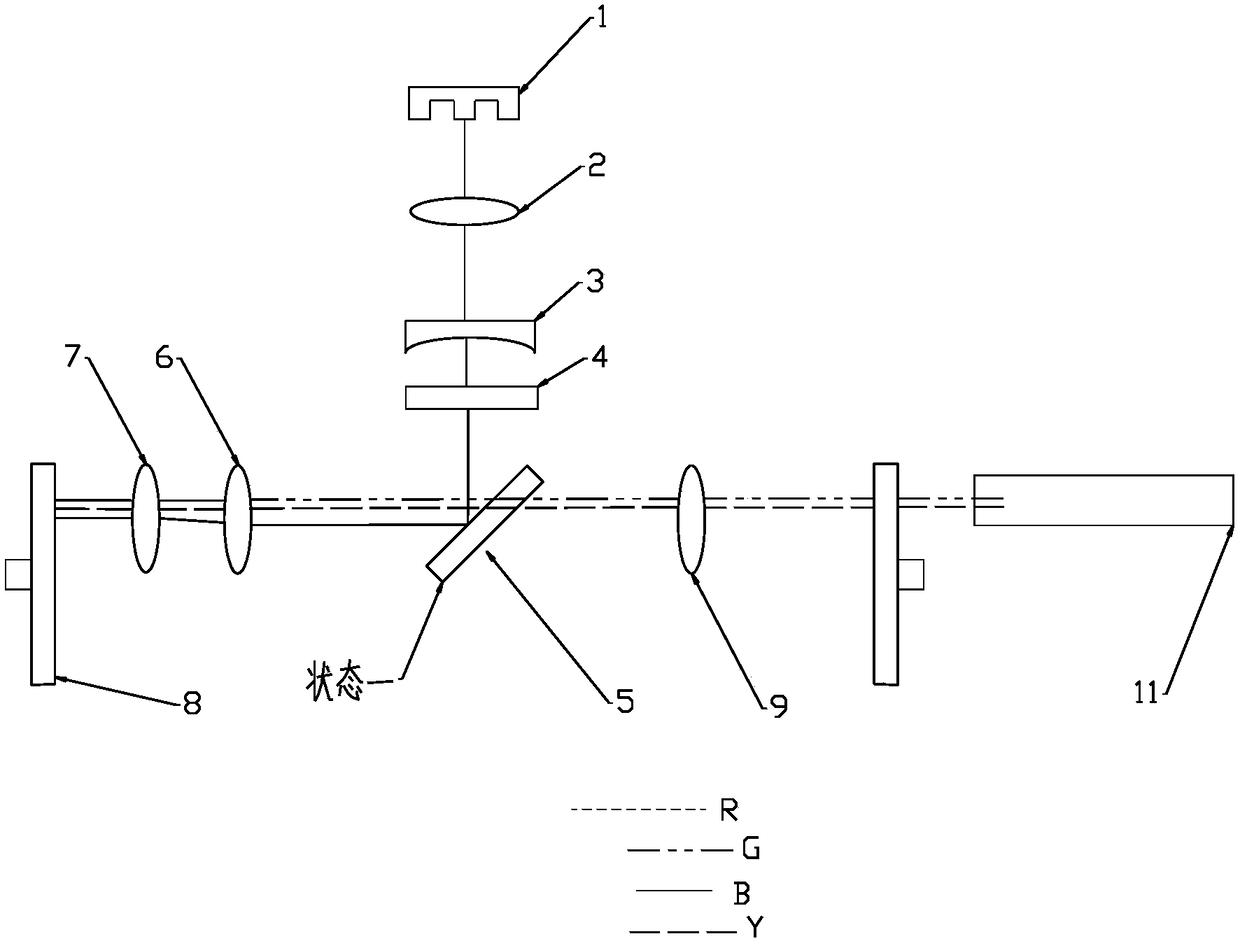

[0164] Such as image 3 , 4 Shown, the basic embodiment two of embodiment three, its difference with embodiment two is:

[0165] The laser source (1) provides green laser besides blue laser and red laser;

[0166] The light-splitting switch element (5) reflects blue laser light, red laser light and green laser light, and transmits light of other colors; when the state is one, the light-splitting switch element (5) uses light from the first diffusion sheet (4) for exciting The blue laser light of the phosphor powder is reflected to the second focusing module, and the laser beam is focused by the second focusing module and illuminates the phosphor powder wheel (8), and the phosphor powder area on the phosphor powder wheel (8) excites yellow fluorescence, and the yellow fluorescence passes through The second focusing module focuses and projects to the second focusing module through the spectroscopic switch element (5), and the fluorescent light focused by the second focusing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com