Solar cell process traceability method

A solar cell and process technology, applied in circuits, electrical components, final product manufacturing, etc., can solve problems such as increasing production costs, increasing the difficulty of process and quality control, and inability to match process parameters before and after, to improve work efficiency, reduce Production cost, the effect of traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

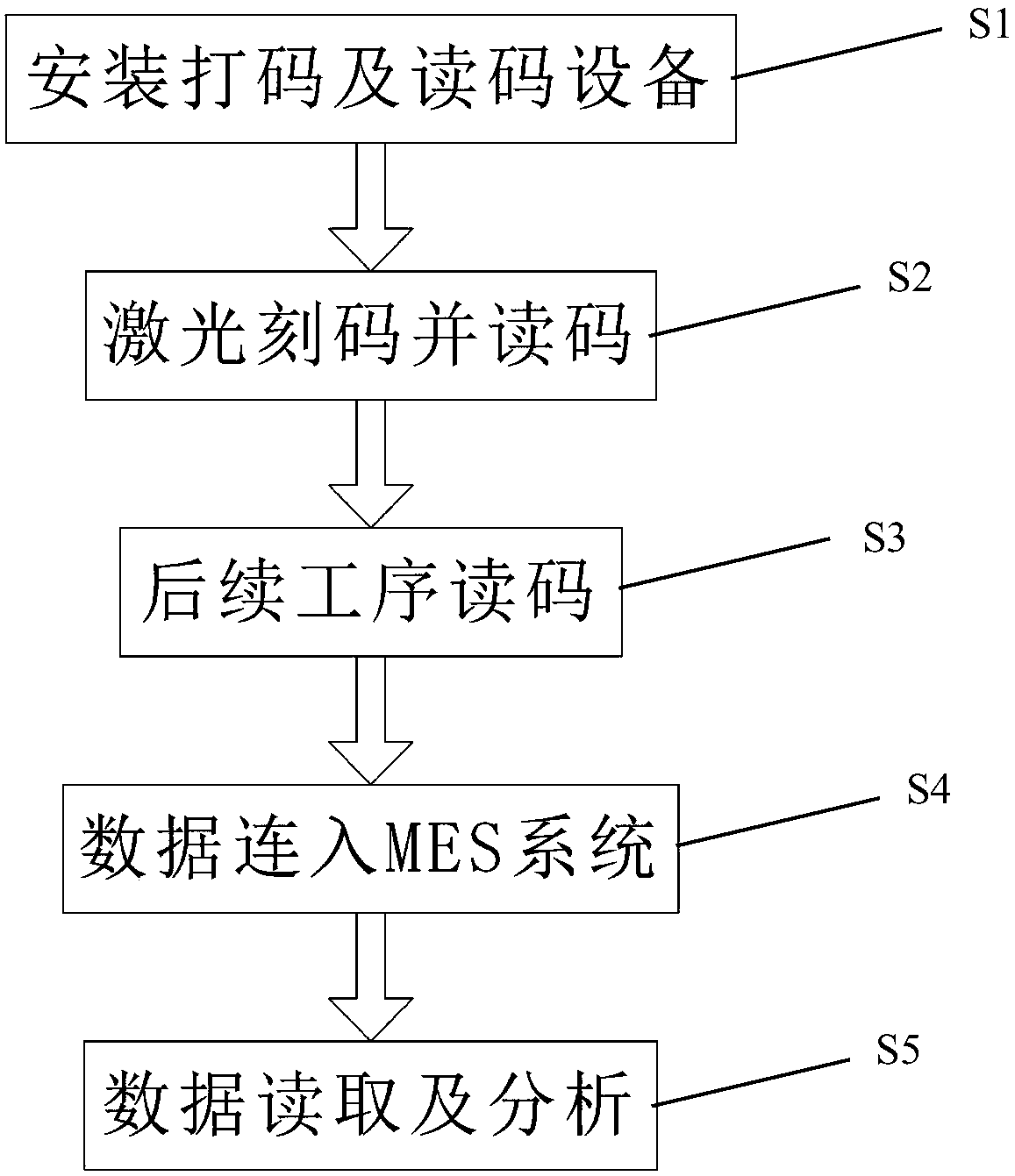

[0022] Such as image 3 As shown, a solar cell manufacturing process traceability method in this embodiment mainly includes the following steps:

[0023] Step S1: Install coding and code reading equipment

[0024] In this embodiment, the coding equipment is integrated after the silicon wafer appearance and electrical performance testing equipment, and the code reading equipment is installed on the silicon wafer appearance and electrical performance testing and subsequent manufacturing equipment.

[0025] The coding equipment in this embodiment adopts laser engraving, which can engrave identification codes on the front side of the silicon wafer. The accuracy of laser marking is ±200um, and the depth of laser marking is 5~50um.

[0026] Step S2: Laser marking and reading

[0027] During the battery production process, the silicon wafers are inspected for their appearance and electrical properties and enter the coding equipment and code reading equipment for laser engraving an...

Embodiment 2

[0042] refer to figure 2 , a solar cell manufacturing process tracing method in this embodiment is basically the same as in Embodiment 1, the difference is that the identification code in this embodiment is a barcode.

[0043] A solar cell manufacturing process traceability method of the present invention uses a laser engraving and code reading recognition system to effectively single-match silicon wafer appearance and electrical performance inspection information and battery process monitoring information through engraving and code reading identification, thereby Realize effective traceability of battery process information. Through traceable information, it is possible to grasp the raw material quality and manufacturing process of each battery. On the one hand, it provides direction for technological improvement; on the other hand, it lays a solid foundation for battery quality. Improve work efficiency and reduce production costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com