OLED backboard and manufacturing method thereof

A manufacturing method and backplane technology, applied in the field of OLED backplane and OLED backplane production, can solve the problems of high production cost and restrictions on large-scale commercialization of OLED displays, and achieve low production cost, avoiding the influence of light, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

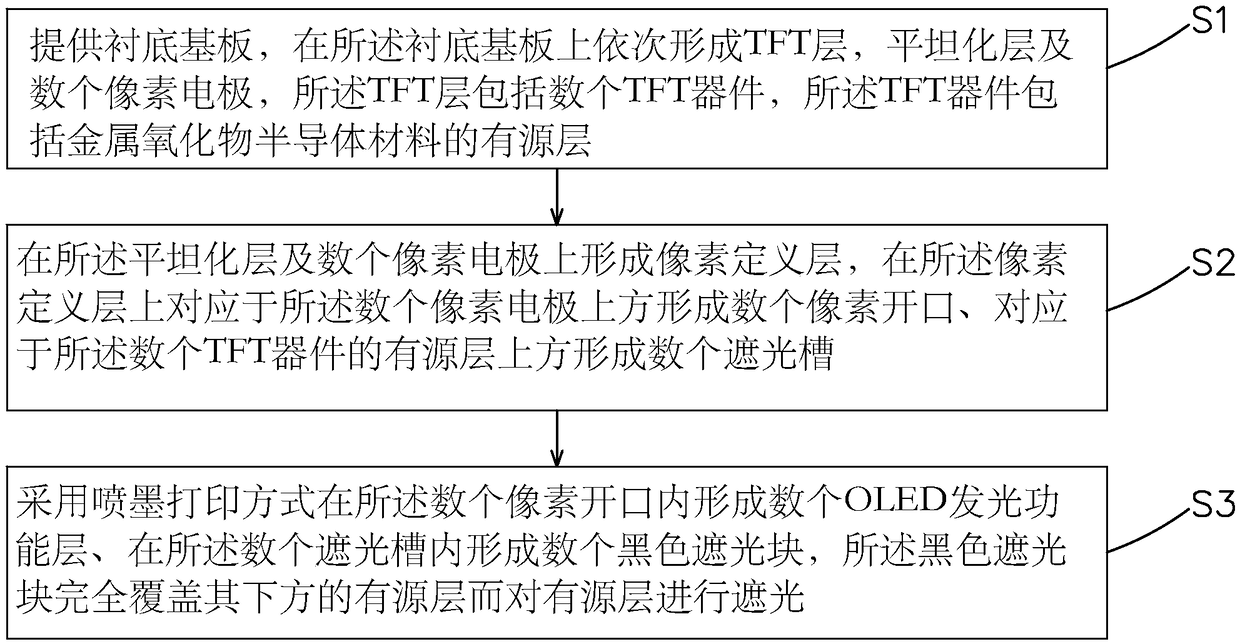

[0036] See figure 1 , The present invention first provides a method for manufacturing an OLED backplane, including the following steps:

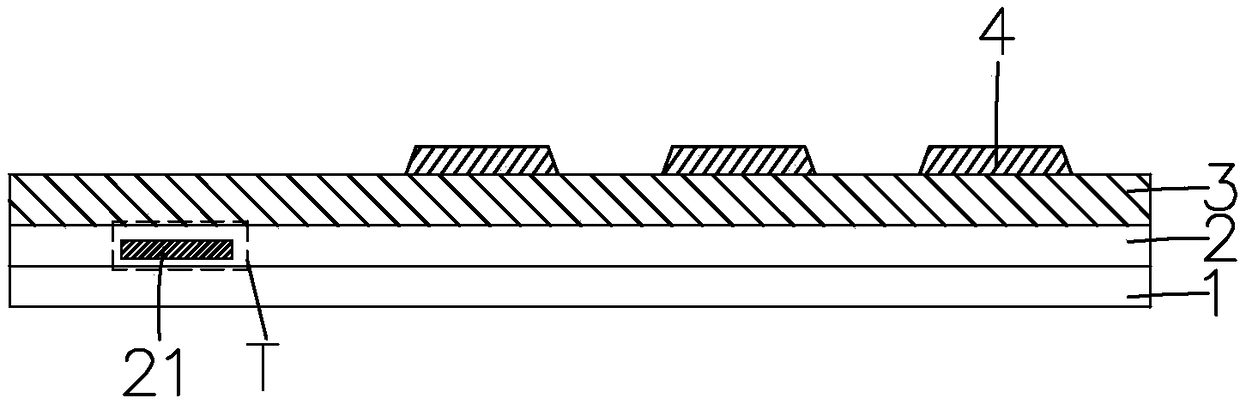

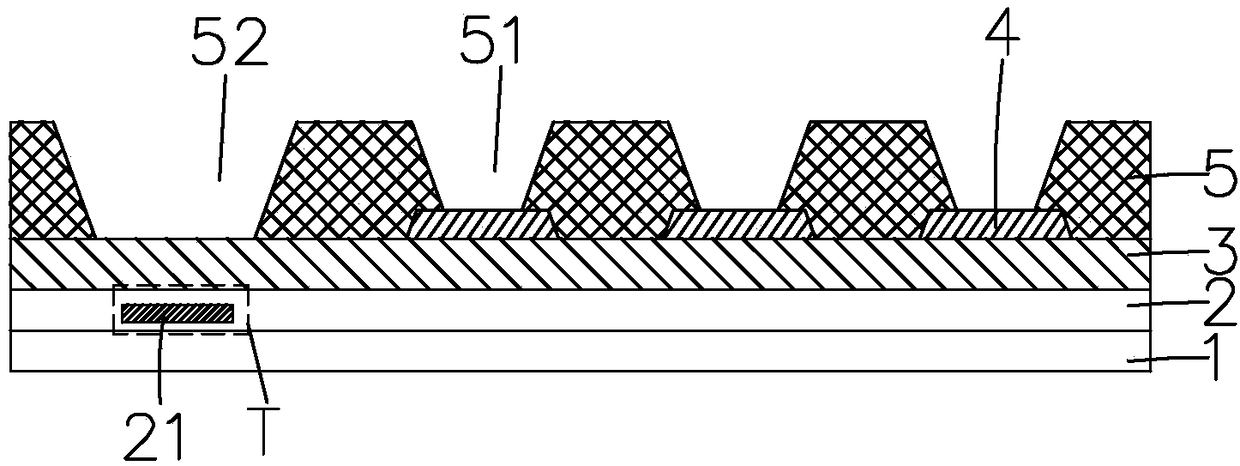

[0037] Step S1, such as figure 2 As shown, a base substrate 1 is provided, a TFT layer 2 is formed on the base substrate 1, a planarization layer 3 is formed on the TFT layer 2, and a number of pixel electrodes 4 are formed on the planarization layer 3; The TFT layer 2 includes several TFT devices T, and the TFT devices T include an active layer 21, and the material of the active layer 21 is a metal oxide semiconductor material.

[0038] Specifically, in the step S1, the material of the active layer 21 may be indium gallium zinc oxide (IGZO), indium zinc tin oxide (IZTO), indium gallium zinc tin oxide (IGZTO) and other metal oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com