Environment-friendly anti-UV flame-retardant polyethylene material and preparation method thereof

A flame-retardant polyethylene and environmental protection technology, applied in the field of environmental protection and anti-UV flame-retardant polyethylene materials and their preparation, can solve the problems of poor weather resistance and aging of polyethylene materials, and achieve improved anti-aging performance, good weather resistance, The effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned environment-friendly anti-UV flame-retardant polyethylene material comprises the following steps:

[0043] 1) Add LDPE, decabromodiphenylethane, antimony trioxide, titanium dioxide and lubricant into a high-speed mixer and mix evenly, then add antioxidant and anti-UV agent, mix evenly;

[0044] 2) The material in step 1) is transferred to a co-rotating twin-screw extruder for mixing and extruding, and after cooling, it is drawn, pelletized, and screened to obtain an environmentally friendly anti-UV flame-retardant polyethylene material.

[0045] Preferably, the screw diameter of the co-rotating twin-screw extruder described in step 2) is 75-95 mm, the length-to-diameter ratio of the screw is 44:1, and the temperature of each zone is: 100-115 °C in the first section, and 100-115 °C in the second section to the second section. The fourth stage is 160-170°C, the fifth stage is 165-160°C, and the head is 160°C.

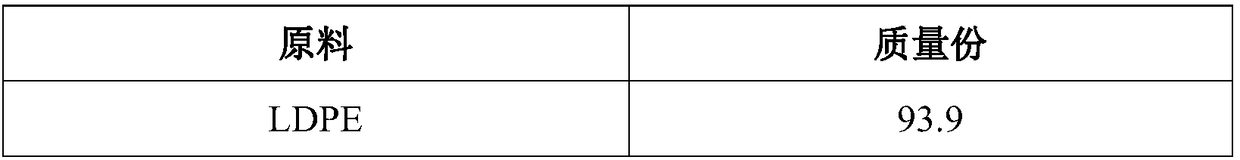

Embodiment 1

[0048] An environmentally friendly anti-UV flame-retardant polyethylene material, its raw material composition is shown in the following table:

[0049] Table 1 The raw material composition of an environmentally friendly anti-UV flame-retardant polyethylene material

[0050]

[0051]

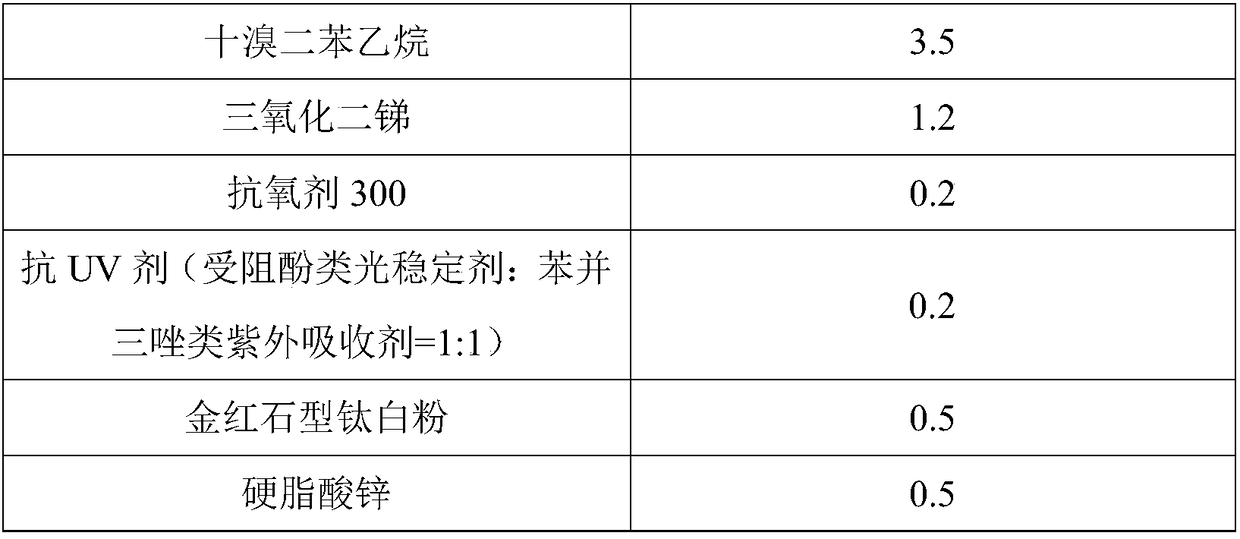

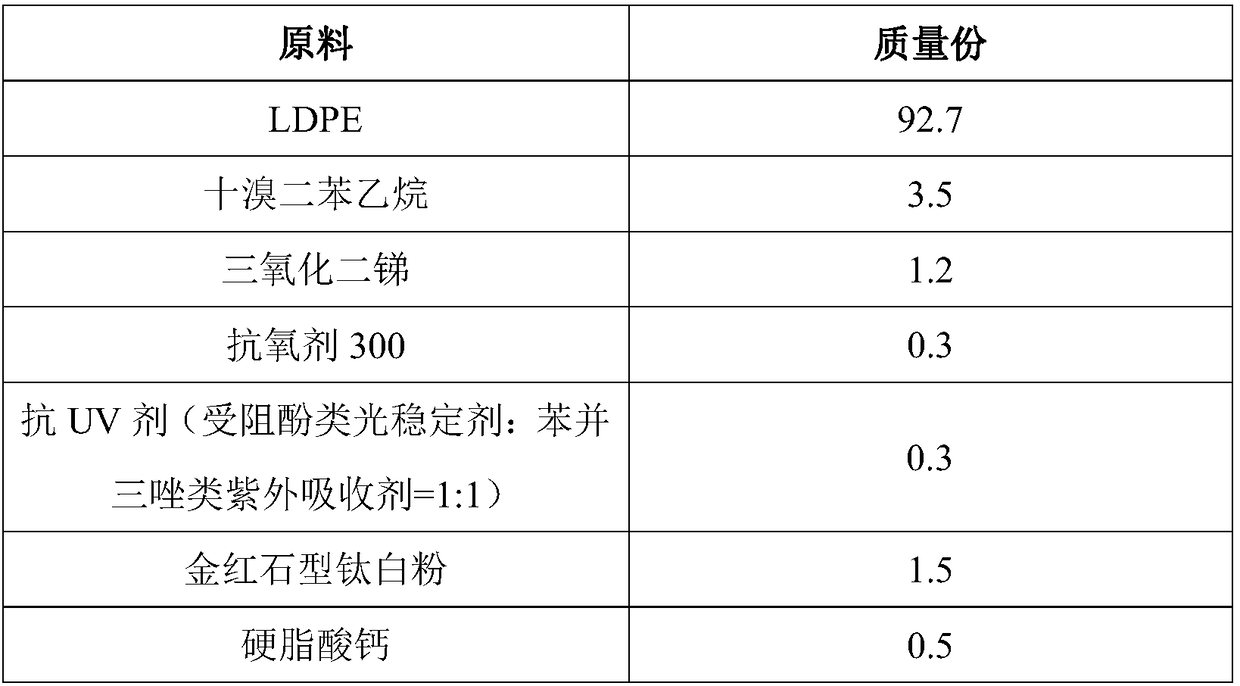

Embodiment 2

[0053] An environmentally friendly anti-UV flame-retardant polyethylene material, its raw material composition is shown in the following table:

[0054] Table 2 The raw material composition of an environmentally friendly anti-UV flame-retardant polyethylene material

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com