Photovoltaic conductive backboard and photovoltaic cell module

A conductive backplane and photovoltaic cell technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of increasing battery fragments and hidden cracks, increasing the difficulty of production, etc., to reduce output power loss, improve component efficiency, reduce The effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

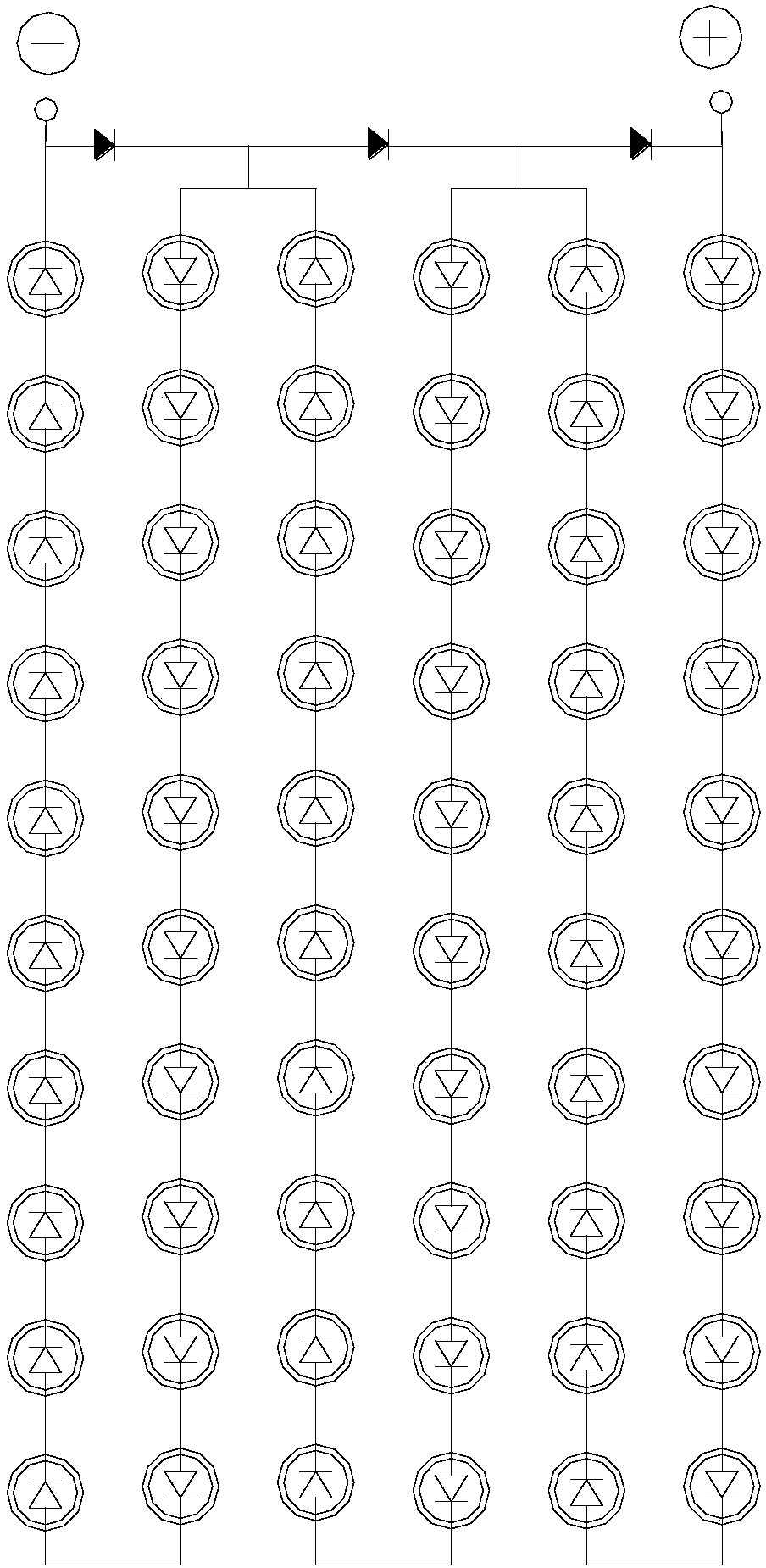

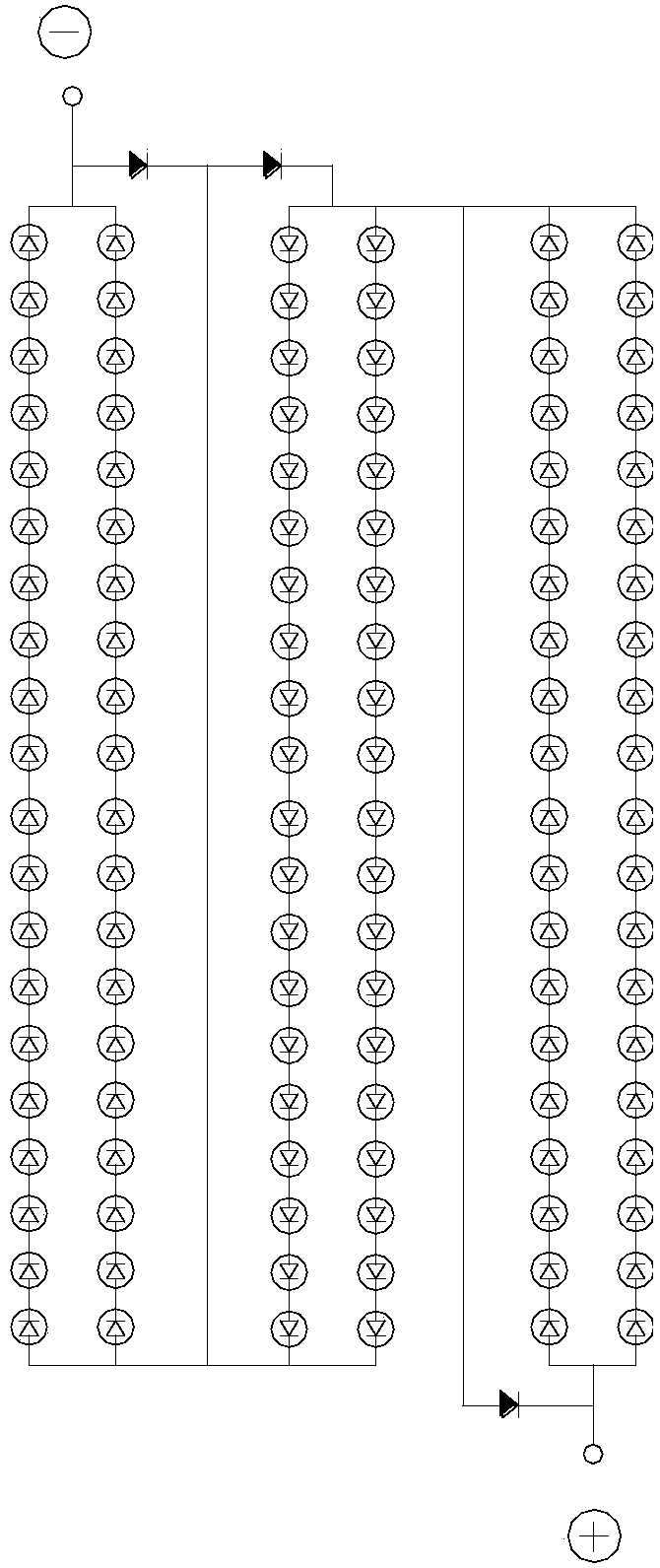

[0033] The invention relates to a photovoltaic cell assembly, which includes a photovoltaic cell and a back plate matched with the photovoltaic cell. The back plate of the photovoltaic cell assembly of the present invention is a back plate with electrical conductivity, and the present invention can design a matching and ohmic connected battery according to the arrangement of the photovoltaic cells and the connection with the bypass diode 9 The backplane circuit structure of the bypass diode 9 enables the photovoltaic cell to be connected to the conductive structure on the backplane, and at the same time, the bypass diode 9 is connected.

[0034] Such as Figure 4 ~ Figure 7As shown, the present invention includes a board 1, and also includes a plurality of first conductive structures 2 compounded at one end of the inner side of the board 1 and arranged at intervals, and a plurality of second conductive structures 2 compounded at the other end of the inner side of the board 1 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap