Electromagnetic progressive mold-free integral compound forming method and device for metal sheets

A technology of composite forming and sheet metal parts, applied in the field of part forming and manufacturing, it can solve the problems of poor surface forming quality and inability to form integral parts of sheet metal parts, shorten the forming cycle, solve the problems of mold design and processing, and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] An embodiment of the present invention provides an electromagnetic progressive moldless integral forming device for sheet metal parts, which includes a discharge coil and a blank holder assembly, wherein,

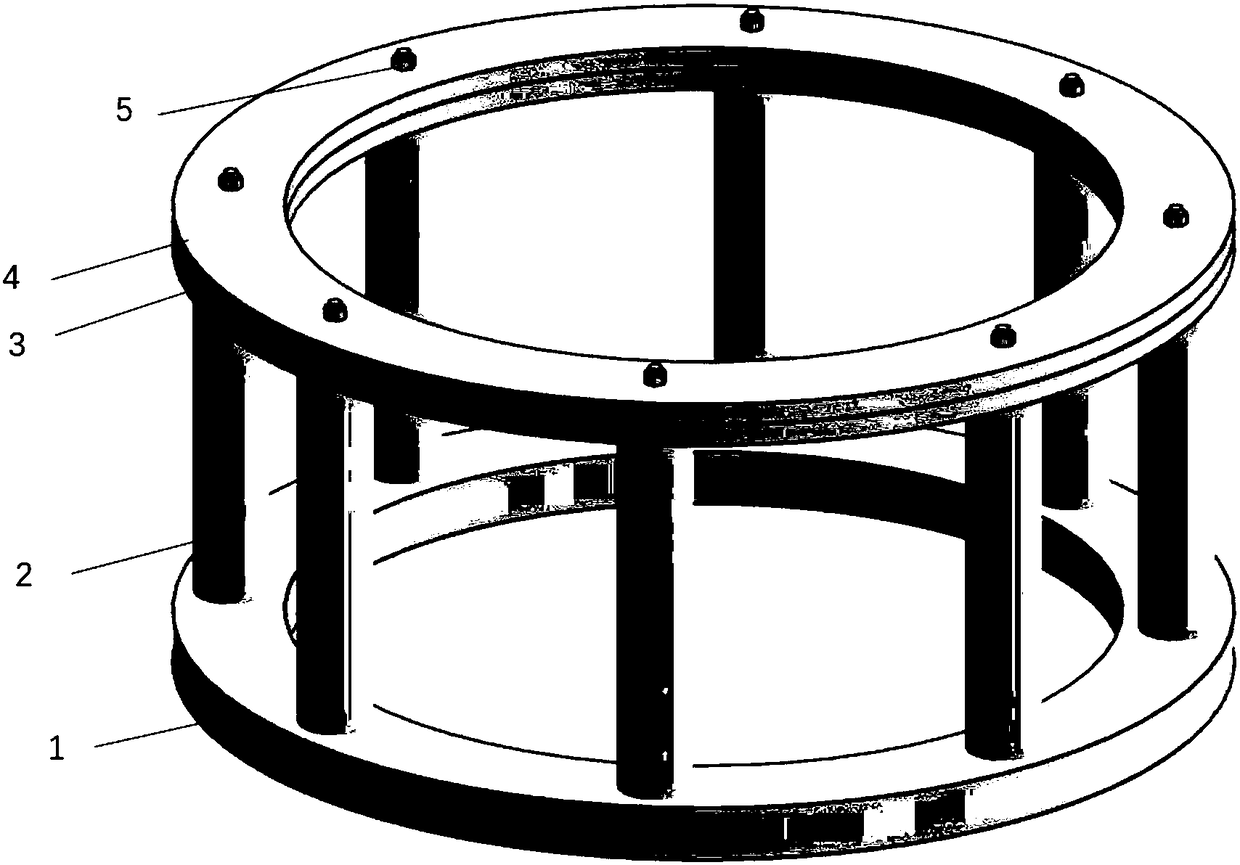

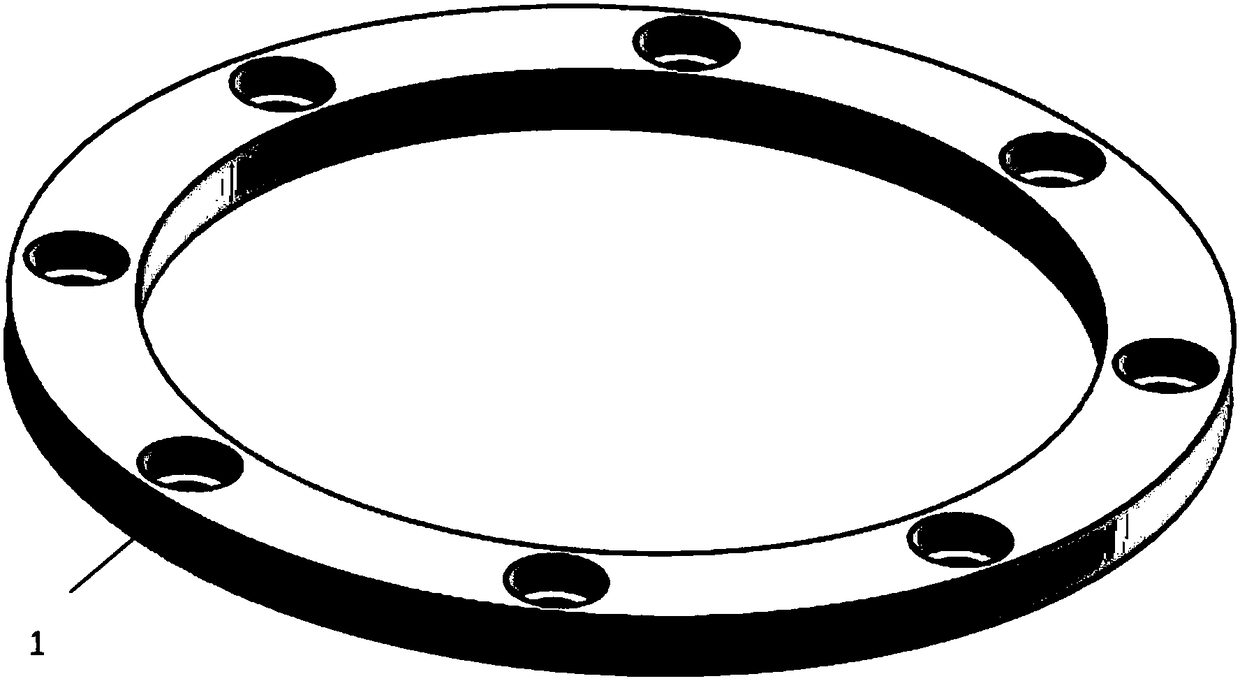

[0065] The discharge coil is a planar spiral coil, the number of coil layers is 1 to 3 layers, and the cross section of the coil wire adopts a rectangular cross section. Such as figure 1 Shown is a blank holder assembly, which includes an upper blank holder 4, a lower blank holder 3, a support rod 2, and a base 1, wherein the inner and outer diameters of the upper and lower blank holders are designed according to the size of the specific target forming part, and the upper and lower press The matching edge rings can clamp and fix the plate 6 to be formed; the upper and lower edge rings are provided with 8 pairs of perforations in one-to-one correspondence;

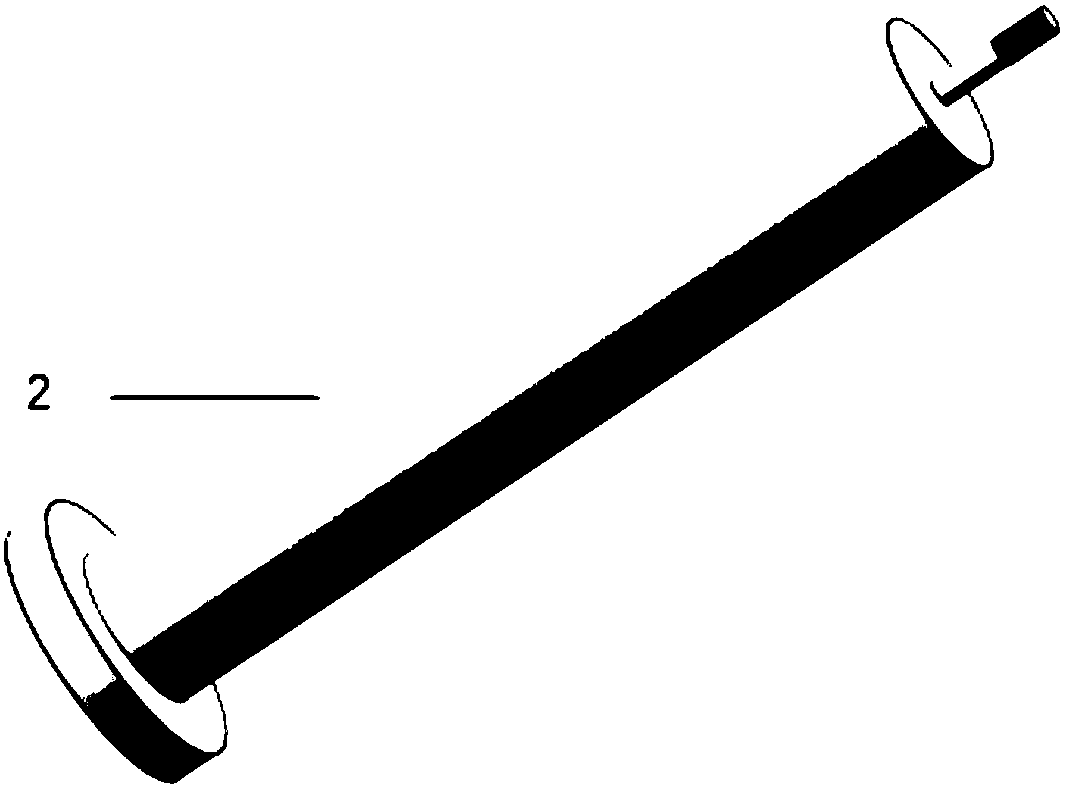

[0066] Such as figure 2 Shown is support rod 2, and there are 8 support rods 2, each support rod 2 has a bos...

Embodiment 2

[0069] Assume that the shape of the target formed part is a bulge with a maximum diameter of 1000mm, a thickness of 3mm, and a maximum depth of 400mm, made of aluminum alloy.

[0070] Such as Figure 4 As shown, it is the technical roadmap of the electromagnetic progressive moldless overall composite forming method. It uses finite element simulation first, and compares the size of the simulated part with the size of the part to be formed. If the two are consistent, the simulated discharge parameters and discharge path can be used. Carry out moldless electromagnetic progressive forming, otherwise reset the discharge parameters and discharge path. Finally, the coreless spinning equipment is used for precise shaping. Through the above process, the precise overall forming of sheet metal parts can be realized.

[0071] Specifically, the electromagnetic progressive moldless overall composite forming method in this embodiment includes the following steps:

[0072] Step 1: Design t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com