Follow-up sliding narrow gap type submerged arc welding device

A submerged arc welding, narrow gap technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low welding quality, inconvenient welding, and inability to ensure the straightness of the weld bead, and achieve high reliability and improved The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

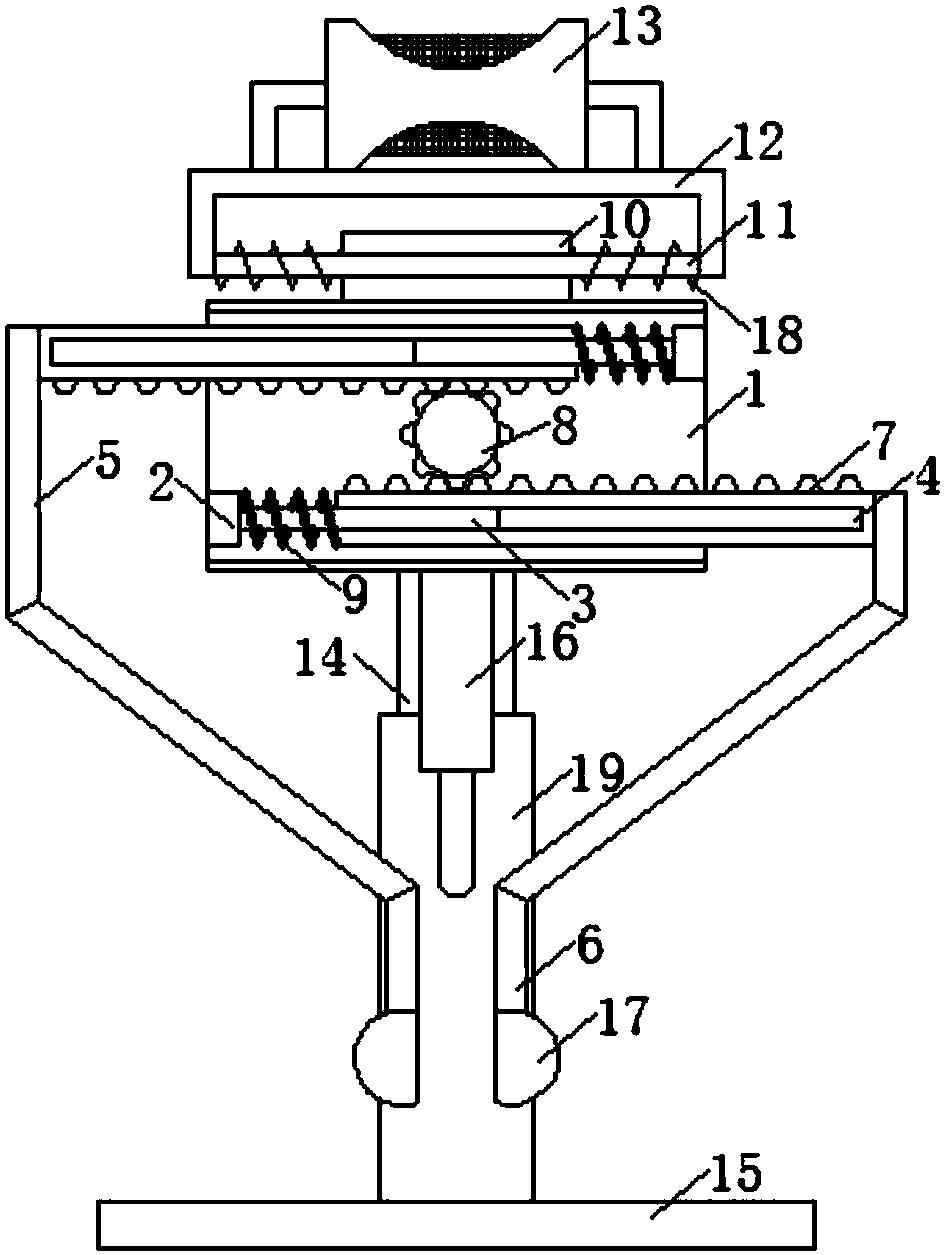

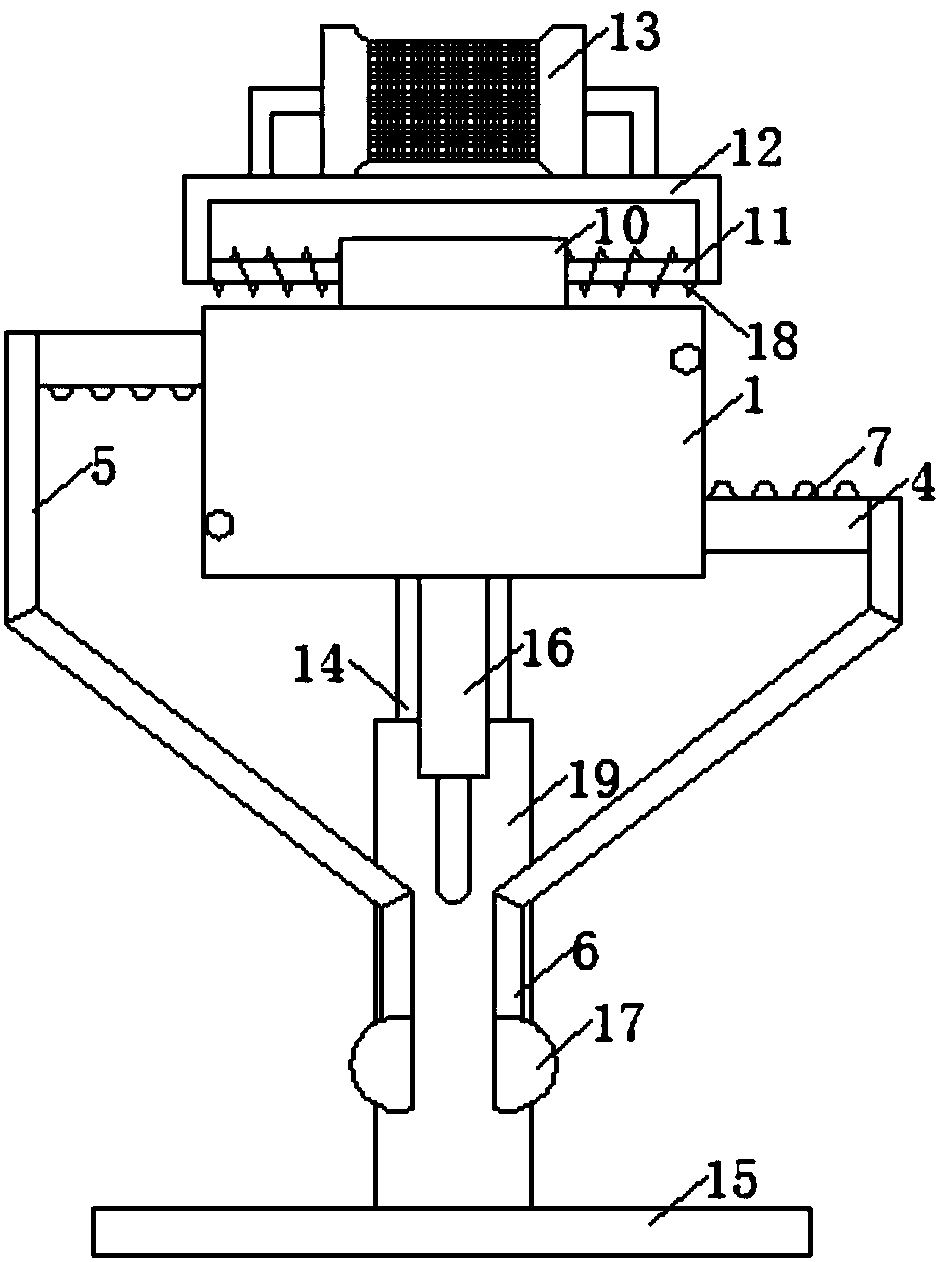

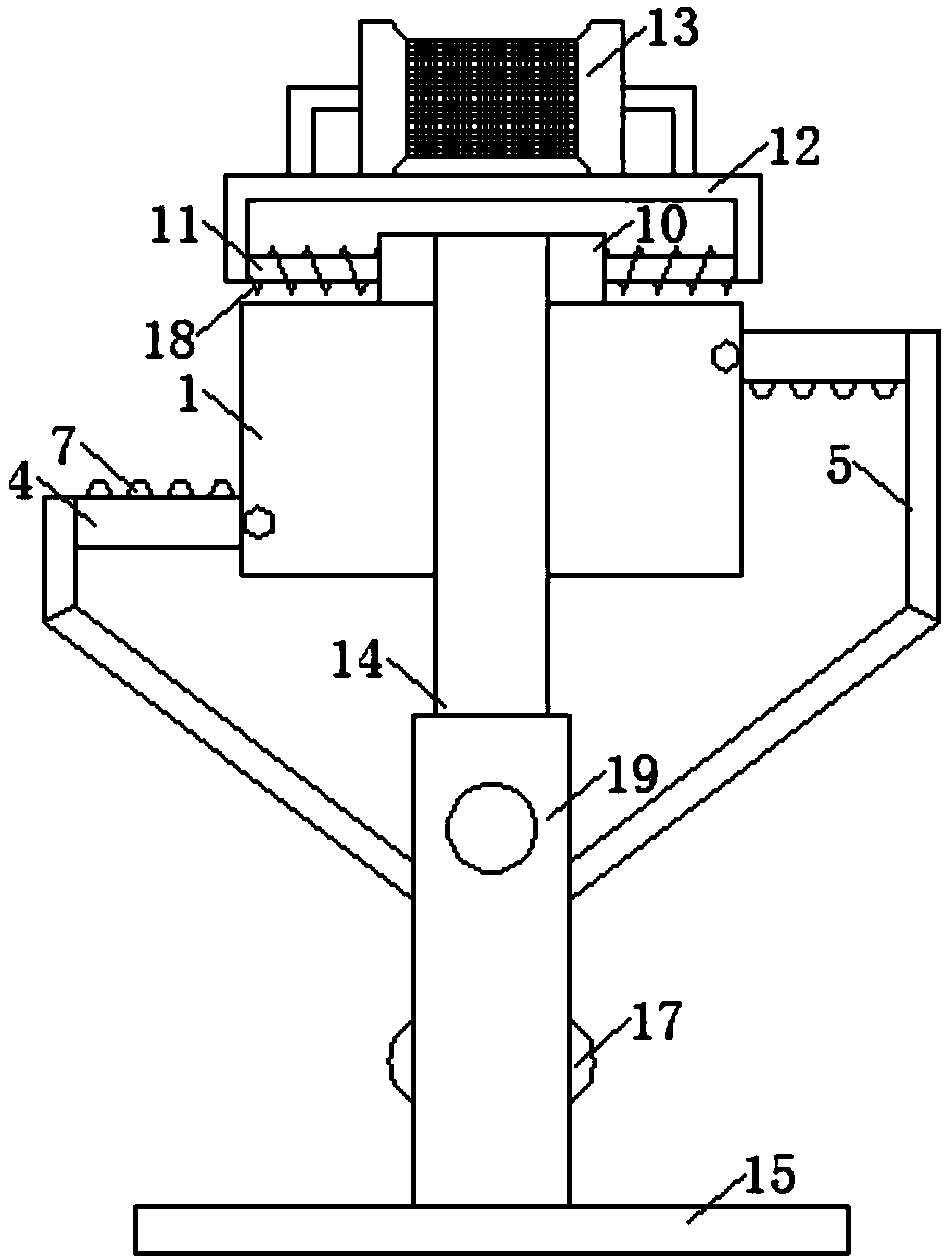

[0019] Such as Figures 1 to 5 As shown, a follow-up sliding narrow-gap submerged arc welding device includes a cylinder body 1, where the weld seam is annular, that is, two pipes are paired together, and a rotating device is provided under the pipe to drive the pipe to rotate. The welding torch 16 For welding, the cylinder body 1 is a square shape with both left and right ends open, and the inner cavity of the cylinder body 1 is provided with two left and right fixing blocks 2, and the left fixing block 2 is located at the lower side of the inner cavity of the cylinder body 1, and the right side The fixed block 2 is located on the upper side of the inner cavity of the cylinder body 1, and the fixed block 2 and the cylinder body 1 are connected by fastening bolts, and the fastening bolts are fixed on the outer end of the cylinder body 1, which is convenient for installation and disassembly. The opposite end of the block 2 is provided with a horizontal square support rod 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com