Mud sleeve assisted double-wall steel cofferdam sinking construction method

A double-wall steel cofferdam and construction method technology, applied in the direction of caisson, infrastructure engineering, construction, etc., can solve the problems of long construction period and low efficiency, and achieve the effect of saving engineering cost, reducing the degree of damage, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

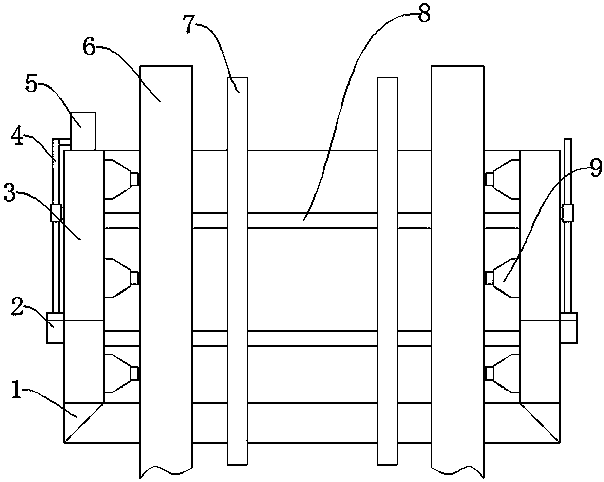

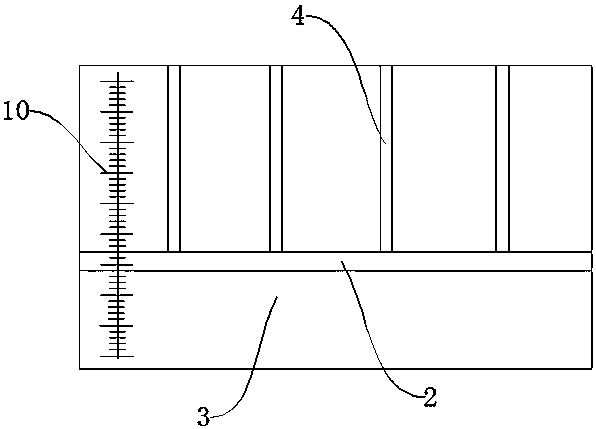

[0028] The present invention will be further described below in conjunction with accompanying drawing:

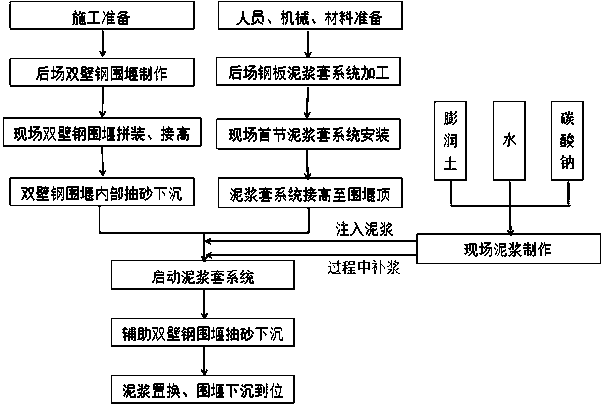

[0029] Such as Figure 1-Figure 3 As shown, a mud jacket-assisted double-wall steel cofferdam sinking construction method includes the following steps:

[0030] a. Preparations before construction, connect the water and electricity pipelines at the construction site of the double-wall steel cofferdam, arrange the construction site, prepare equipment, staffing, and materials, and analyze and understand the engineering geology in detail according to the geological exploration data and construction design and hydrogeological conditions, conscientiously prepare the construction organization design, and formulate the construction monitoring plan;

[0031] b. The double-walled steel cofferdam in the back field is manufactured, and the double-walled steel cofferdam is processed in sections in the bank processing yard, and the steel plate mud sleeve is processed in blocks at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com