Blank casting positioning control system and method for continuous casting machine

A technology of positioning control and continuous casting machine, applied in the field of control system, can solve the problems of manual operation of billet roller table, high labor intensity of operators, large consumption of spare parts, etc., achieve accurate and reliable casting billet tracking and positioning, and improve Effects of labor productivity and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

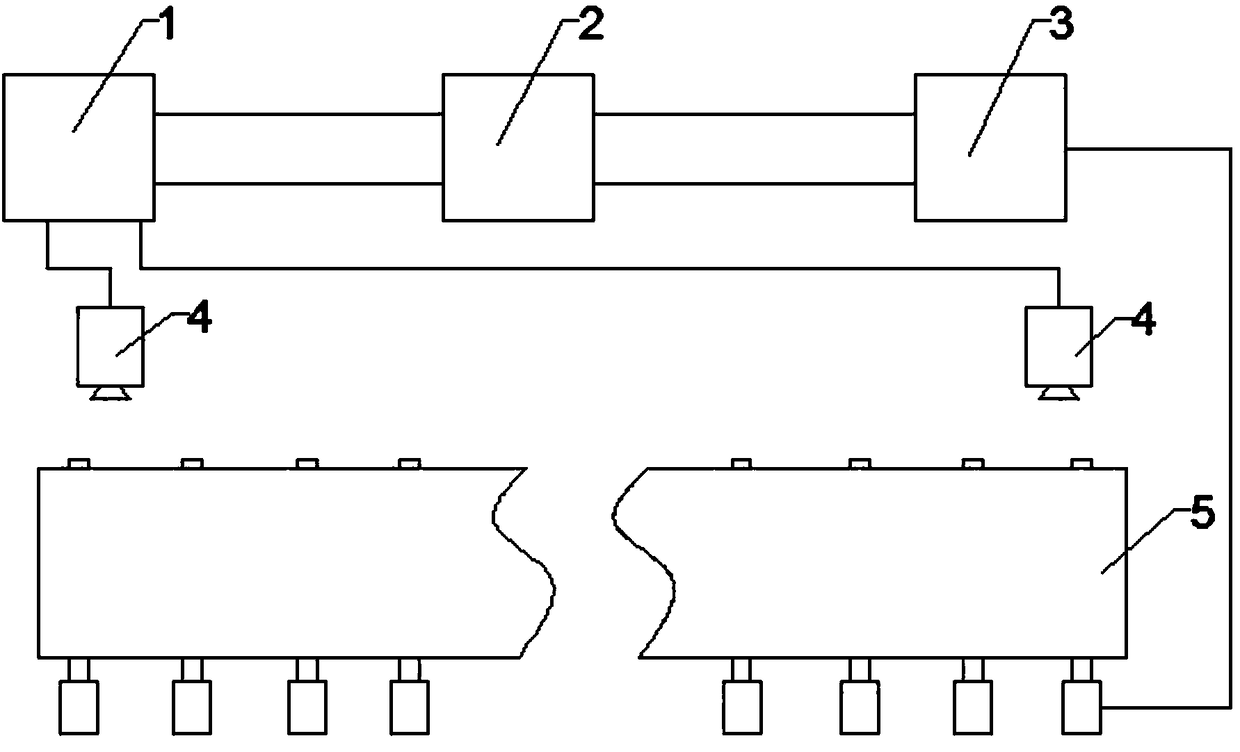

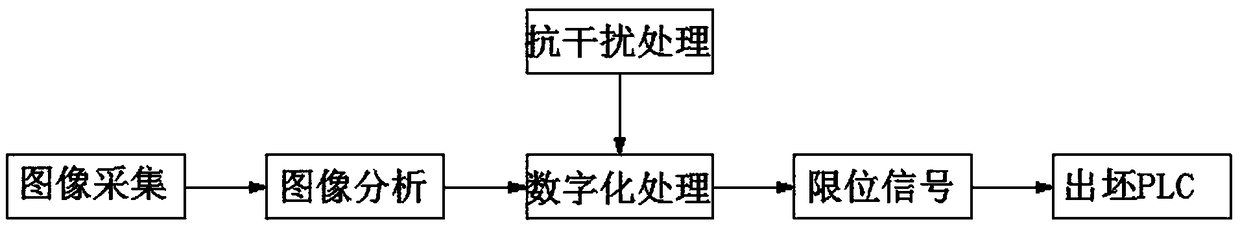

[0021] Such as figure 1 and figure 2 As shown, the continuous casting machine billet positioning control system of the present invention includes an infrared camera 4, a special machine for picture processing 1, a relay box 2 and a PLC controller 3 for billet discharge, and an infrared camera 4, a special machine for picture processing 1, and a relay box 2 and the billet discharge PLC controller 3 are electrically connected in turn, the infrared camera 4 is arranged outside the entrance and exit of the billet roller table 5, and is facing the billet roller table 5, and the billet discharge PLC controller 3 can control the billet roller Start and stop of road 5. Those skilled in the art can understand that, in the actual production process, there will be many sets of roller table 5 and they are in a high-temperature environment. In this system, the infrared camera 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com