Industrial cold end circulating water optimization and energy saving control system

A technology of energy-saving control system and central control system, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve problems such as difficulty in achieving optimal operating state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

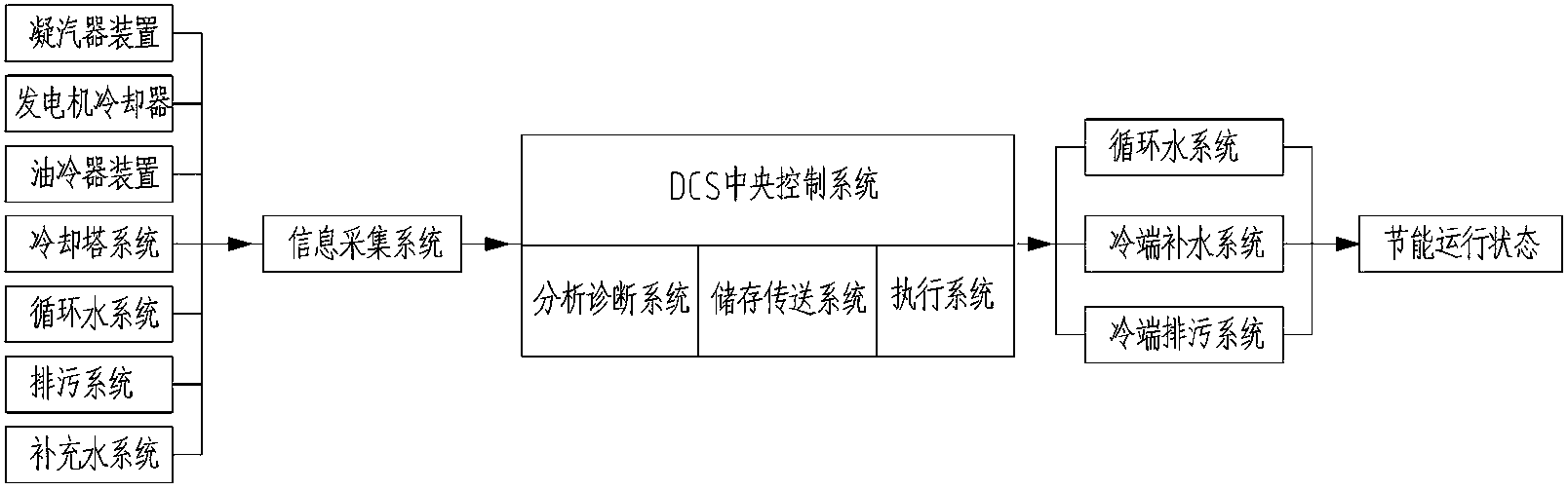

[0027] like figure 1 An industrial cold-end circulating water optimization energy-saving control system shown includes an information collection system, a DCS central control system, a circulating water system, a cold-end replenishment system, and a cold-end sewage discharge system.

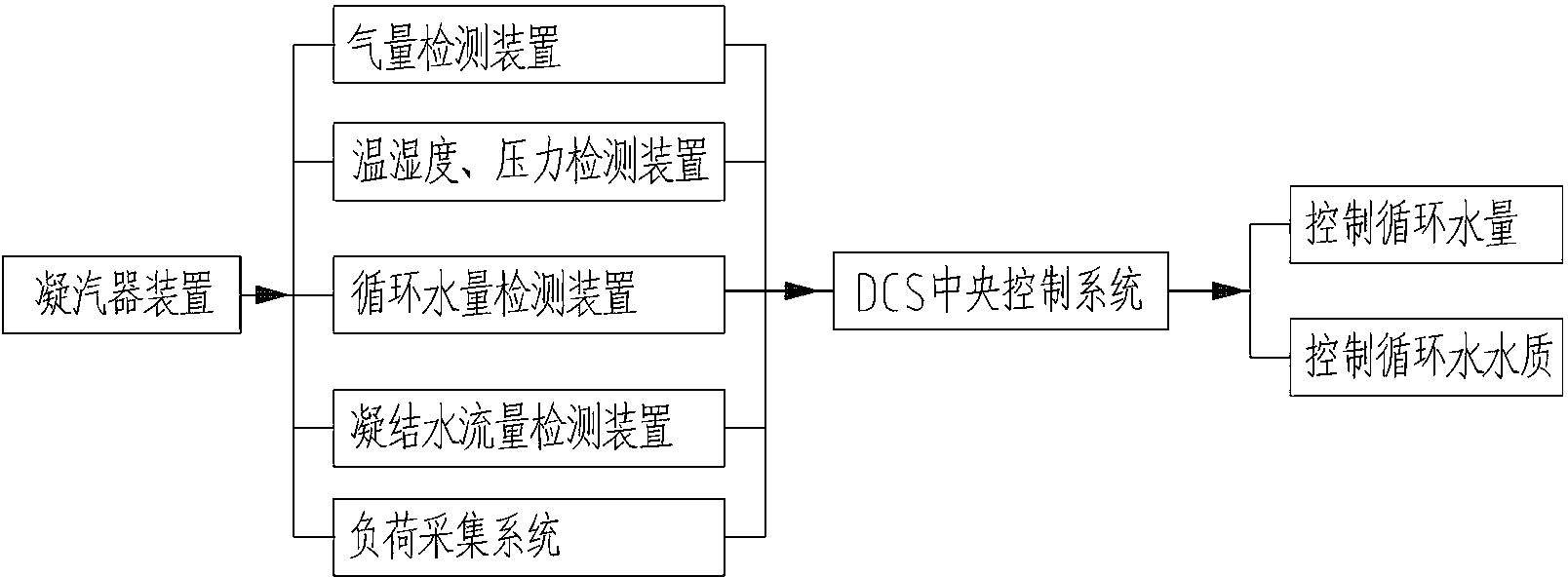

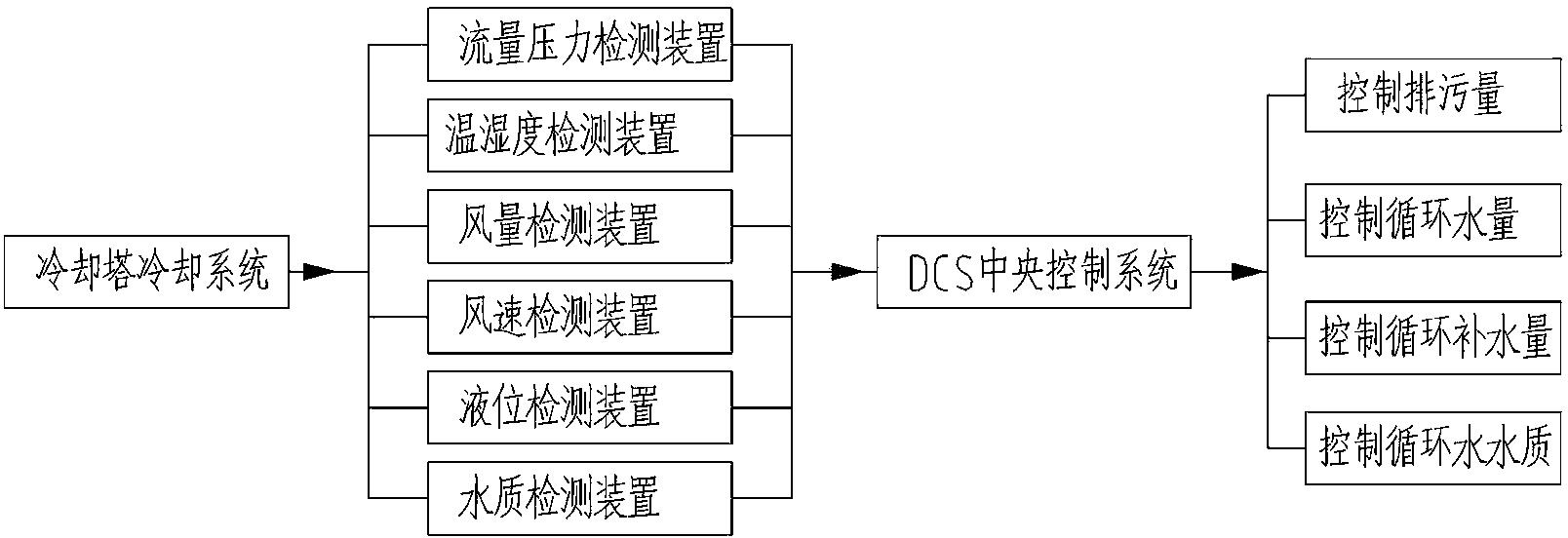

[0028] The information collection system collects relevant information of the equipment, and transmits the information to the DCS central control system, and the DCS central control system controls the circulation water system, the cold end water supply system and the cold end sewage system to make the system reach the best operating state . The information collection system can collect information related to condenser devices, generator cooler devices, oil cooler devices, cooling tower systems, circulating water systems, supplementary water systems, and sewage systems.

[0029] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com