Electrostatic adsorption panel

An electrostatic adsorption, panel technology, applied in the direction of static electricity, electrical components, etc., can solve the problems of unfavorable going out, the impact of electrostatic strength is large, and the use conditions are harsh, so as to improve the barrier and waterproof efficiency, realize the electrostatic adsorption force, and prevent breakdown and leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

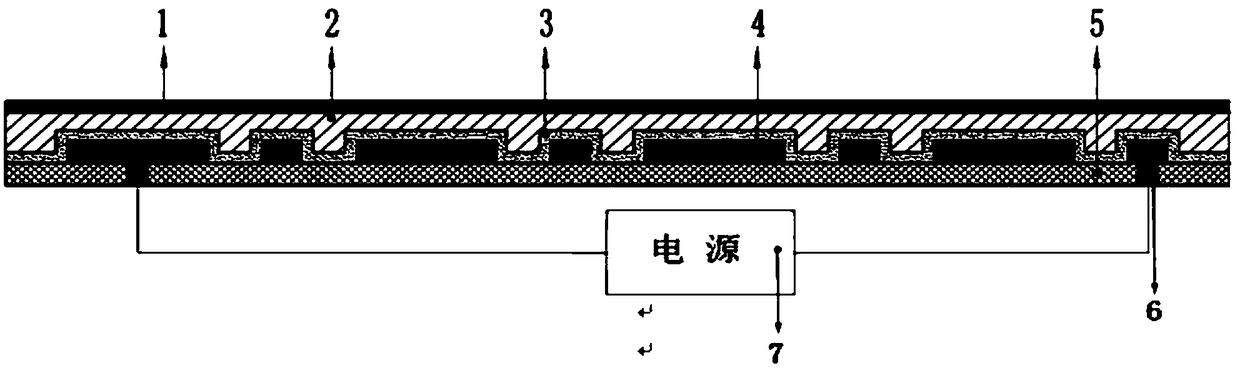

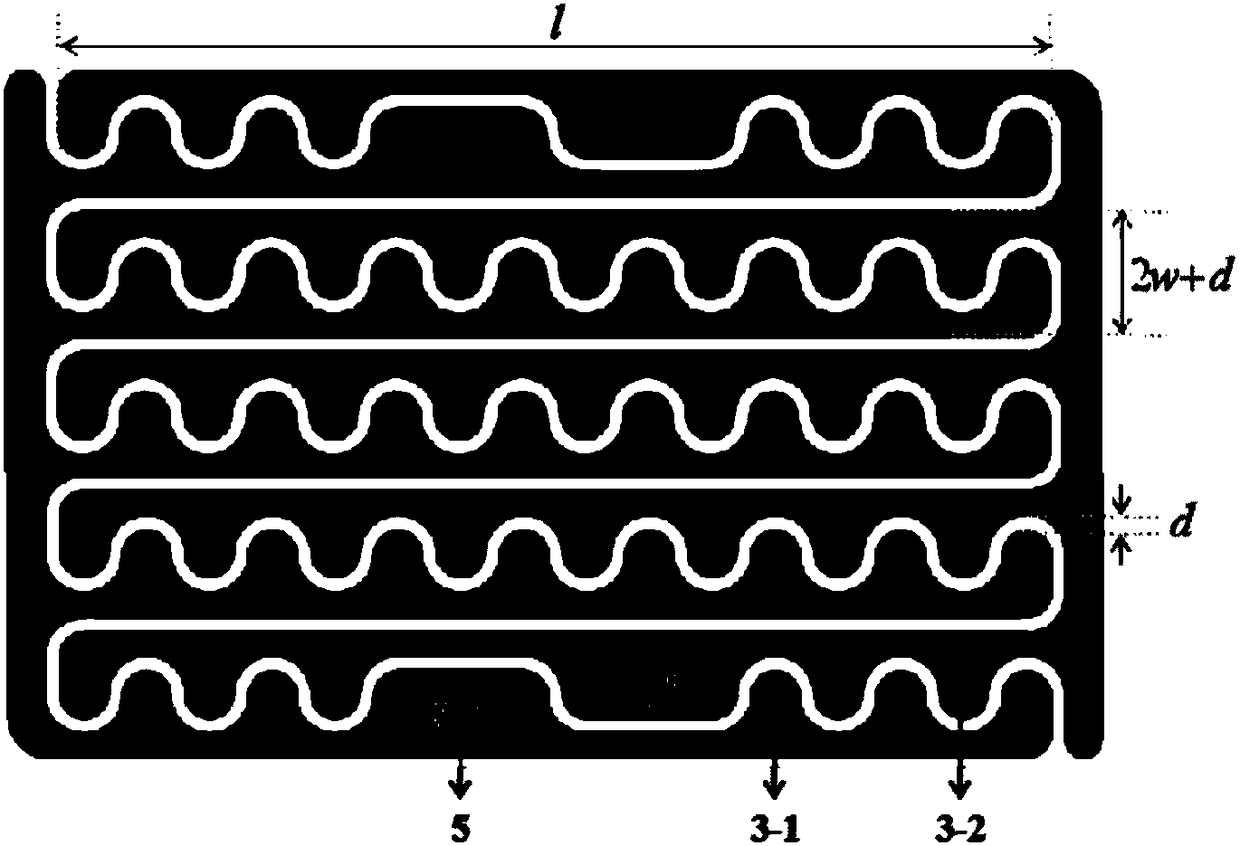

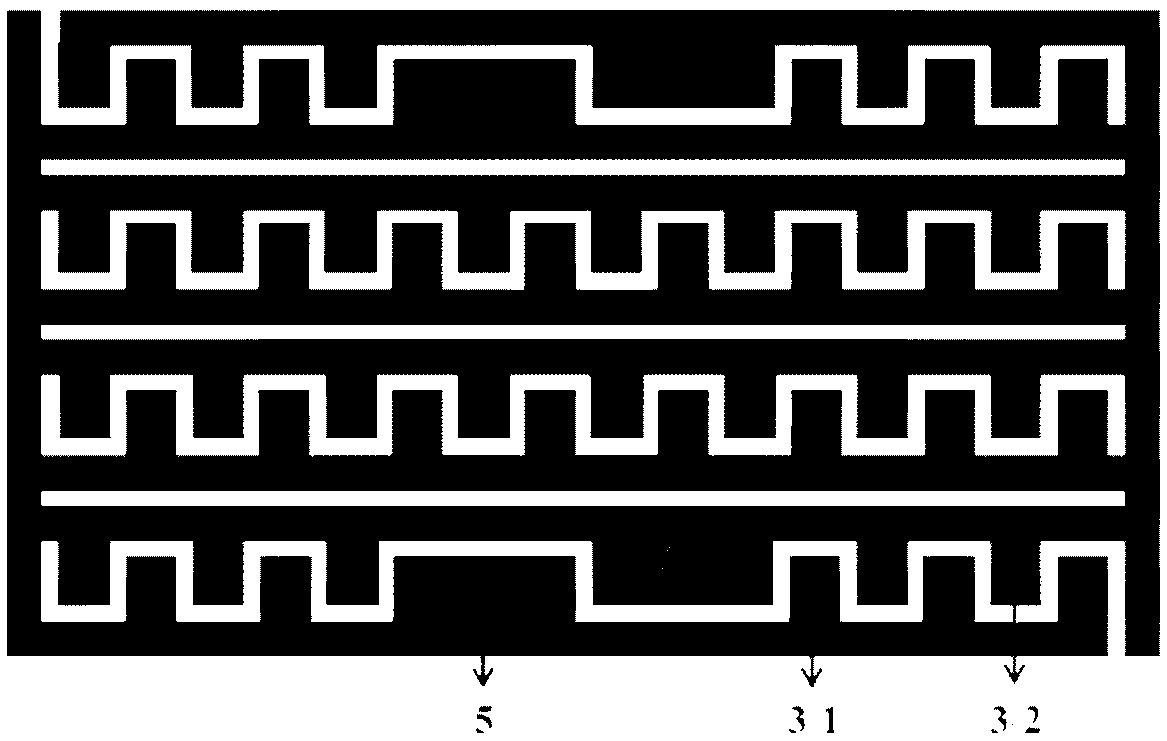

[0043] The electrostatic adsorption panel includes a functional medium layer, an insulating layer, a barrier layer, an electrode layer and an insulating substrate layer arranged in sequence from top to bottom, and the functional medium layer, insulating layer and barrier layer adopt a multi-layer composite structure with precisely controlled thickness; The barrier layer covers the surface of the electrode layer completely without gaps, and is seamlessly connected with the insulating layer; the insulating layer and the electrode layer adopt a parallel cross-complementary arrangement structure in the horizontal direction.

[0044] Among them, the functional medium layer is composed of 1 or 2 layers of functional insulating materials, and its overall thickness is 0.001mm; the insulating layer is composed of 2 to 9 layers of insulating materials, and its overall thickness is 0.005mm; the thickness of the barrier layer is 0.001mm. The surface hardness of the functional dielectric la...

Embodiment 2

[0050] Other contents are as in Example 1, wherein the functional medium layer is composed of 1 or 2 layers of functional insulating materials, and its overall thickness is 0.025 mm; the insulating layer is composed of 2 to 9 layers of insulating materials, and its overall thickness is 1.0 mm ; Barrier layer thickness is 0.01mm. The surface hardness of the functional dielectric layer can be 2-5H.

[0051] Electrostatic power source selection pulse frequency is 30Hz, voltage is 3000V.

[0052] The electrode structure of the electrode layer consists of one or more sets of parallel crossing electrode pairs; the width of the single pair of electrodes is 50mm, the insulation distance between the single pair of electrodes is 8.0mm, and the thickness of the electrode layer is 0.1mm. The shape of the parallel intersecting electrodes of the electrode layer is a square wave.

[0053] The materials used for the functional medium layer, the insulating layer and the barrier layer are the...

Embodiment 3

[0056] Other contents are as in Example 1, wherein the functional dielectric layer is composed of 1 or 2 layers of functional insulating materials, and its overall thickness is 0.015 mm; the insulating layer is composed of 2 to 9 layers of insulating materials, and its overall thickness is 0.05 mm ; The thickness of the barrier layer is 0.005mm. The surface hardness of the functional dielectric layer can be 2-5H.

[0057] Electrostatic power source selection pulse frequency is 15Hz, voltage is 1500V.

[0058] The electrode structure of the electrode layer is composed of one or more sets of parallel crossing electrode pairs; the width of the single pair of electrodes is 15-50 mm, the insulation distance between the single pair of electrodes is 0.5-8.0 mm, and the thickness of the electrode layer is 0.001-0.1 mm. The parallel intersecting electrode shapes of the electrode layers are parallel straight lines.

[0059] The materials used for the functional medium layer, the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com