Floating supporting and pressing device

A technology of pressing device and floating support, which is applied in the direction of positioning device, support, clamping, etc., can solve the problems of insufficient processing, tool collision, low utilization rate of machine tools, etc., and achieve the effect of improving utilization rate and continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

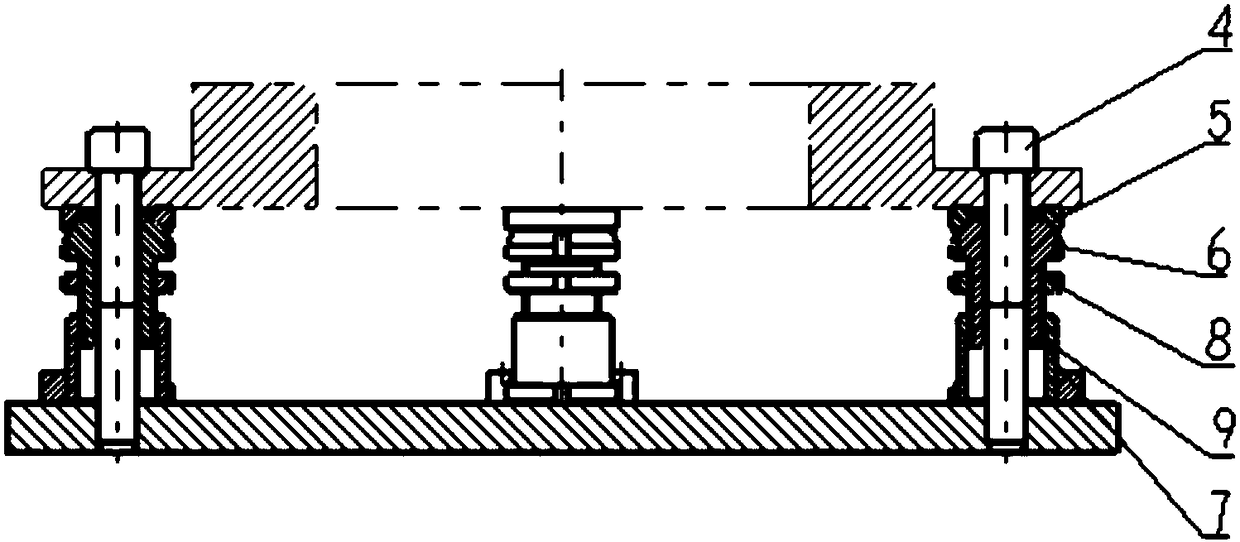

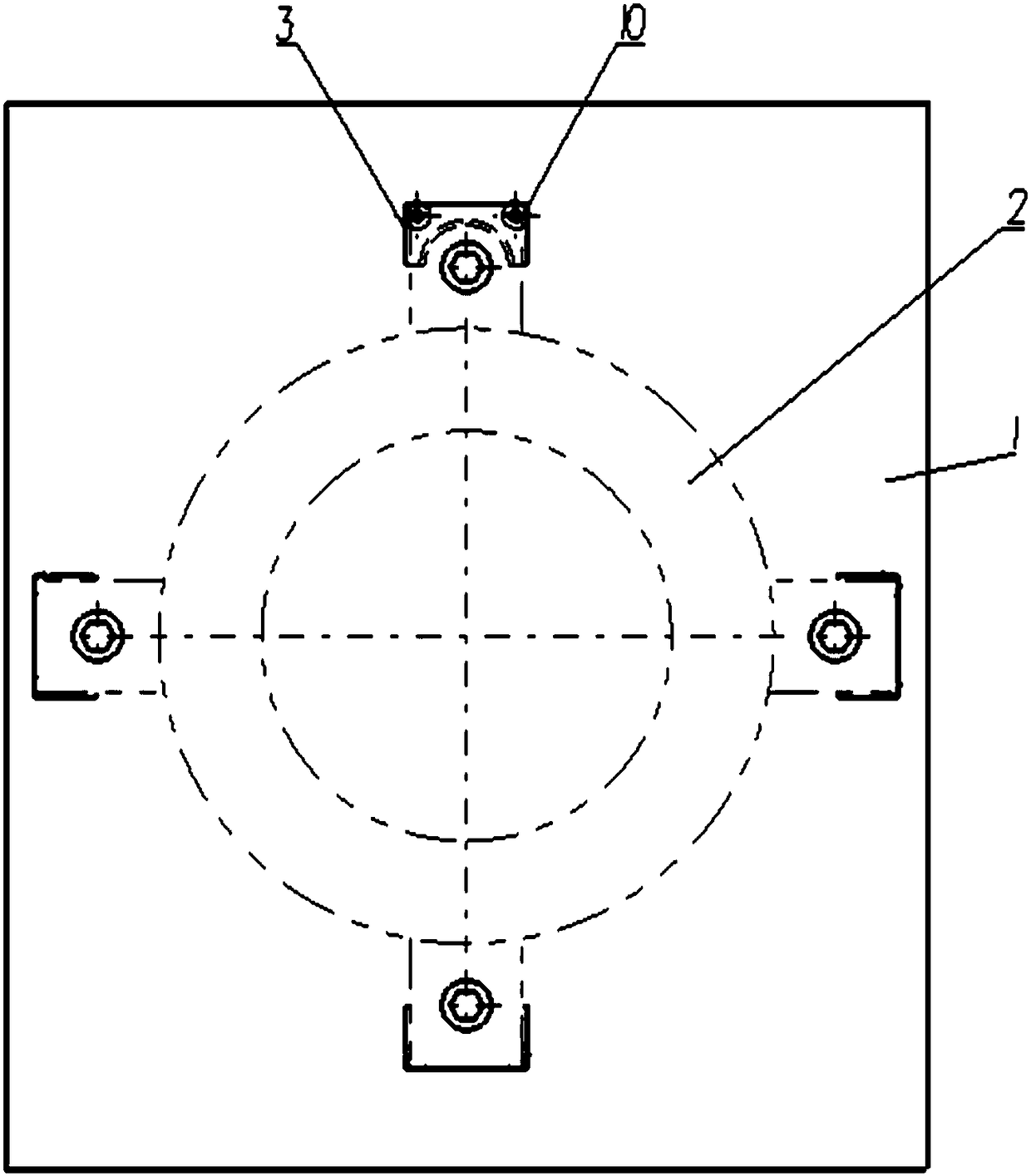

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0014] A floating support and pressing device, which is composed of a universal inner spherical floating head 5 and an outer spherical threaded strut 6 with adjustable threads to form a spherical high pair to achieve angle adjustment within a range of 5 degrees;

[0015] The threaded support rod 6 and the threaded support 7 are screwed together to realize thread lifting and self-locking. The large outer cylindrical surfaces of the threaded support rod 6 and the threaded support 7 are respectively provided with anti-rotation limit card slots for adjustment with a slotted wrench. Lifting; there is a snap ring groove at the end of the threaded rod 6, which is used to install the spring clip 9, so as to prevent the threaded rod 6 from being screwed out of the threaded support 7; The nut 8 realizes the locking o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com