A fruit sorting robot

A technology of manipulators and fruits, which is applied in the field of manipulators, can solve the problems of affecting quality, fruit scratches, and the inability to widely apply fruit sorting, etc., to achieve the effect of preventing slipping and shifting, and preventing fruit slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

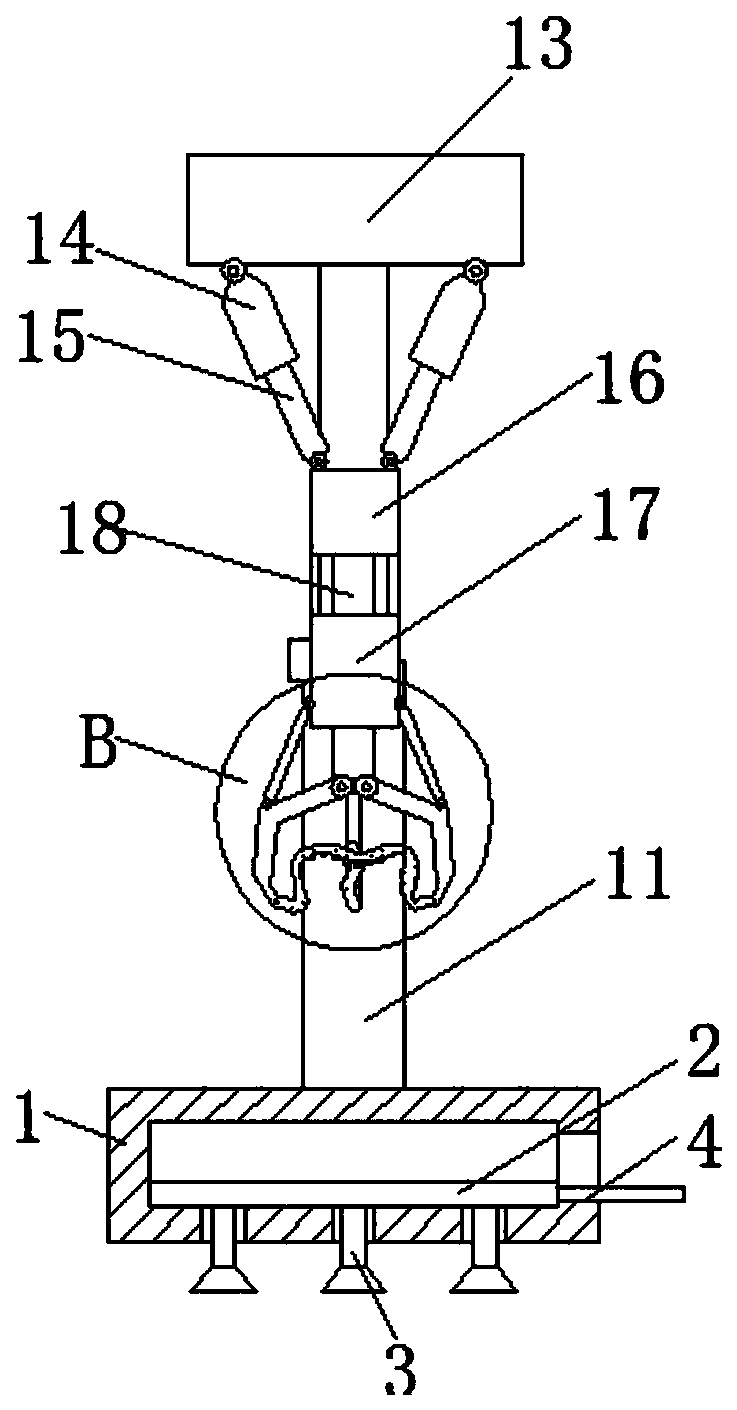

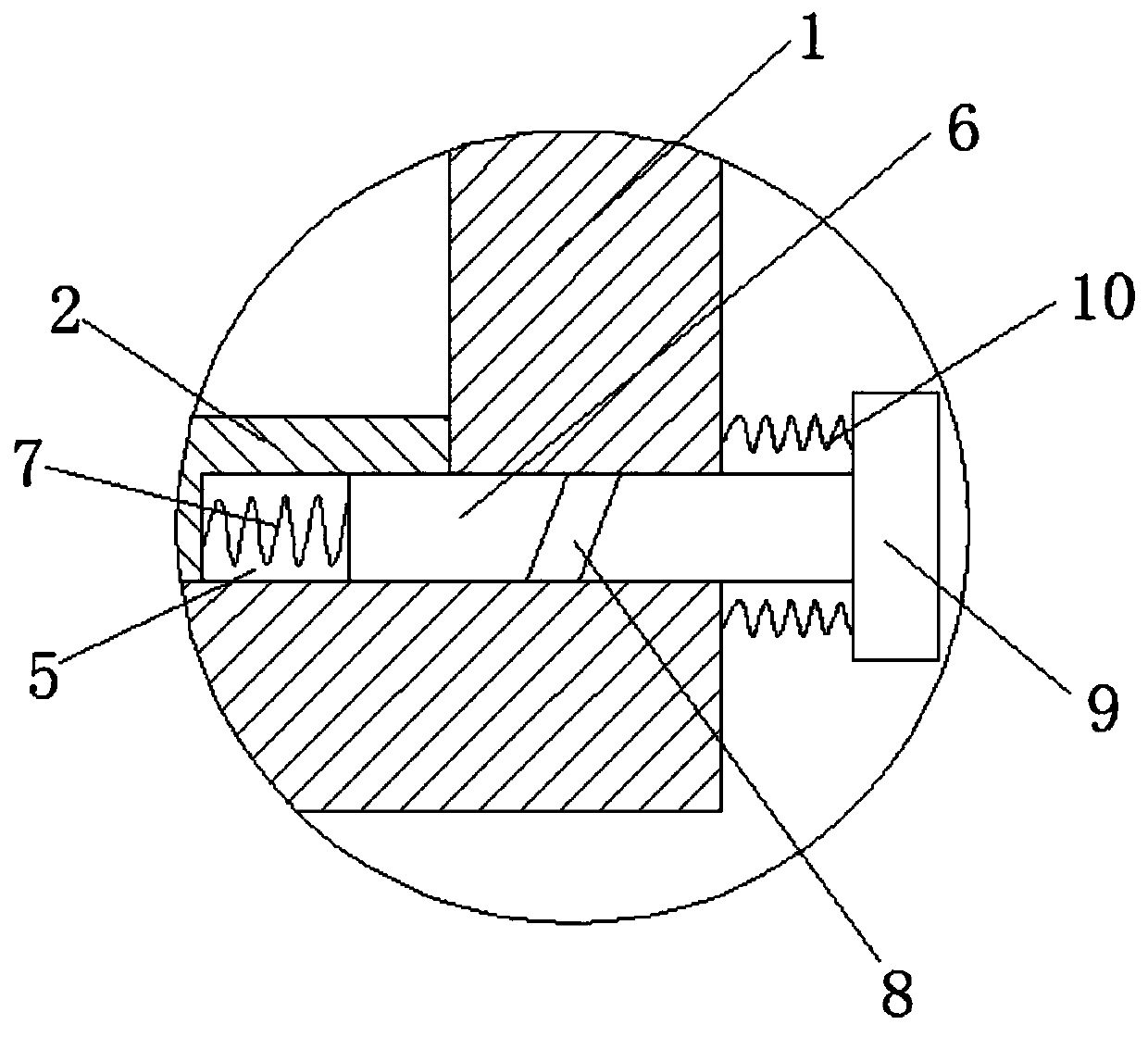

[0024] Embodiment 1: When the manipulator is working on smooth ground, it needs to step on the pressure rod 4 to keep the movable plate 2 still, and pull up the shell of the first push rod motor 11, and the shell of the first push rod motor 11 drives the chassis 1 Moving up, the movable plate 2 moves down relative to the chassis 1, and the movable plate 2 drives the limit block 6 to move relative to the chassis 1 together. When the limit block 6 moves to the limit hole 8, since the first spring 7 has been in a compressed state before, At this time, the first spring 7 bounces back, pushing the stop block 6 into the limit hole 8, and the limit hole limits the movement of the stop block 6, thereby limiting the movement of the movable plate 2 relative to the chassis 1, and the suction cup 3 moves from The outside of the chassis 1 protrudes from the communication hole, and the chassis is adsorbed on the smooth ground, which strengthens the fixing of the device.

Embodiment 2

[0025] Embodiment 2: When the manipulator is working on a non-smooth ground, the suction cup 3 needs to be retracted. At this time, kick or press the movable block 9 with your feet, and the two movable blocks 9 are pressed at the same time. The second spring 10 is compressed, and the movable block One end of 9 extends into the limit hole 8, the limit block 6 is pushed into the connection groove 5, the first spring 7 is compressed, and due to gravity, the chassis 1 falls, the bottom of the chassis 1 contacts the ground, and the suction cup 3 shrinks. Into the interior of the chassis 1, the movable plate 2 moves up relative to the chassis 1, and the contact surface of the limiting block 6 and the movable block 9 is a slope to prevent jamming. The inside slides out, and the first spring 7 is in a compressed state.

Embodiment 3

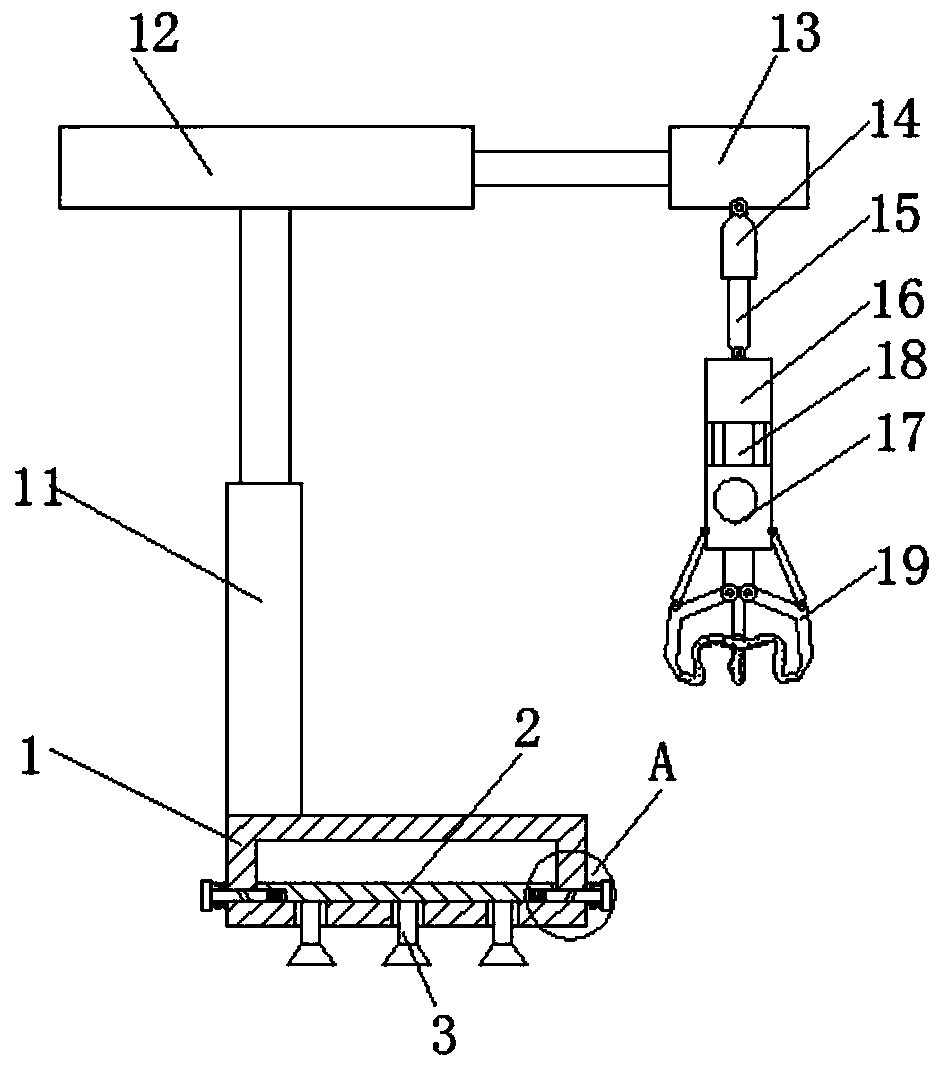

[0026] Embodiment 3: When performing sorting operations, such as sorting apples and pears, the device is connected to the power supply, the miniature camera takes in the lower fruit, and sends the signal to the computer. The computer compares and recognizes the fruit according to the position of the fruit , to locate the fruit, the computer first controls the first push rod motor 11, so that the first push rod protrudes from the inside of the first push rod motor 11, the second push rod motor rises together with the manipulator, and then controls the second push rod motor The second push rod inside 12 stretches to complete the positioning of the y-axis, and then controls the two electric cylinders 14 to make one telescopic rod 15 stretch out and one telescopic rod 15 to retract. Driven by the two telescopic rods 15, the third push rod The rod motor 16 rotates together with the sleeve rod 17 to complete the x-axis positioning. Then, the computer controls the third push rod motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com