Material mixing equipment for producing bricks of garbage incinerator

A technology of waste incinerator and mixing equipment, which is applied in the direction of batching weighing instrument, clay preparation device, mixing operation control, etc. It can solve the problems that refractory bricks cannot meet the needs of use, uneven mixing of materials, waste of resources, etc., and achieve realization Automated operation, reduced labor intensity, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

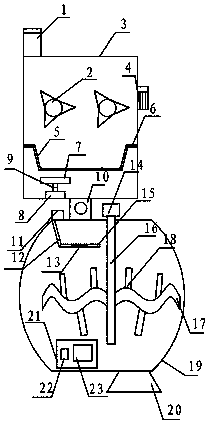

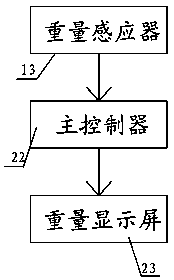

[0020] Such as figure 1 , figure 2 As shown, a kind of mixing equipment for producing bricks for waste incinerators according to the present invention includes a feed port 1, a double-toothed roller 2, a crushing chamber 3, a primary motor 4, a filter plate 5, a lap plate 6, a hammer Head 7, hydraulic pump 8, hydraulic rod 9, discharge port 10, feed port 11, inclined plate 12, weight sensor 13, secondary motor 14, weighing plate 15, rotating shaft 16, main stirring blade 17, auxiliary stirring blade 18. Mixing chamber 19, discharge port 20, main control panel 21, main controller 22, weight display screen 23, feed inlet 1 is set on the crushing chamber 3, double-toothed roller 2 is set in the crushing chamber 3, double-toothed The roller 2 is connected to the primary motor 4, and a filter plate 5 is set in the crushing chamber 3, and the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com