Hybrid power module, hybrid power driving system and vehicle

A hybrid power module and a hybrid power technology are applied to a vehicle, a hybrid power drive system, and the above-mentioned hybrid power drive system. field, able to solve problems such as layout problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

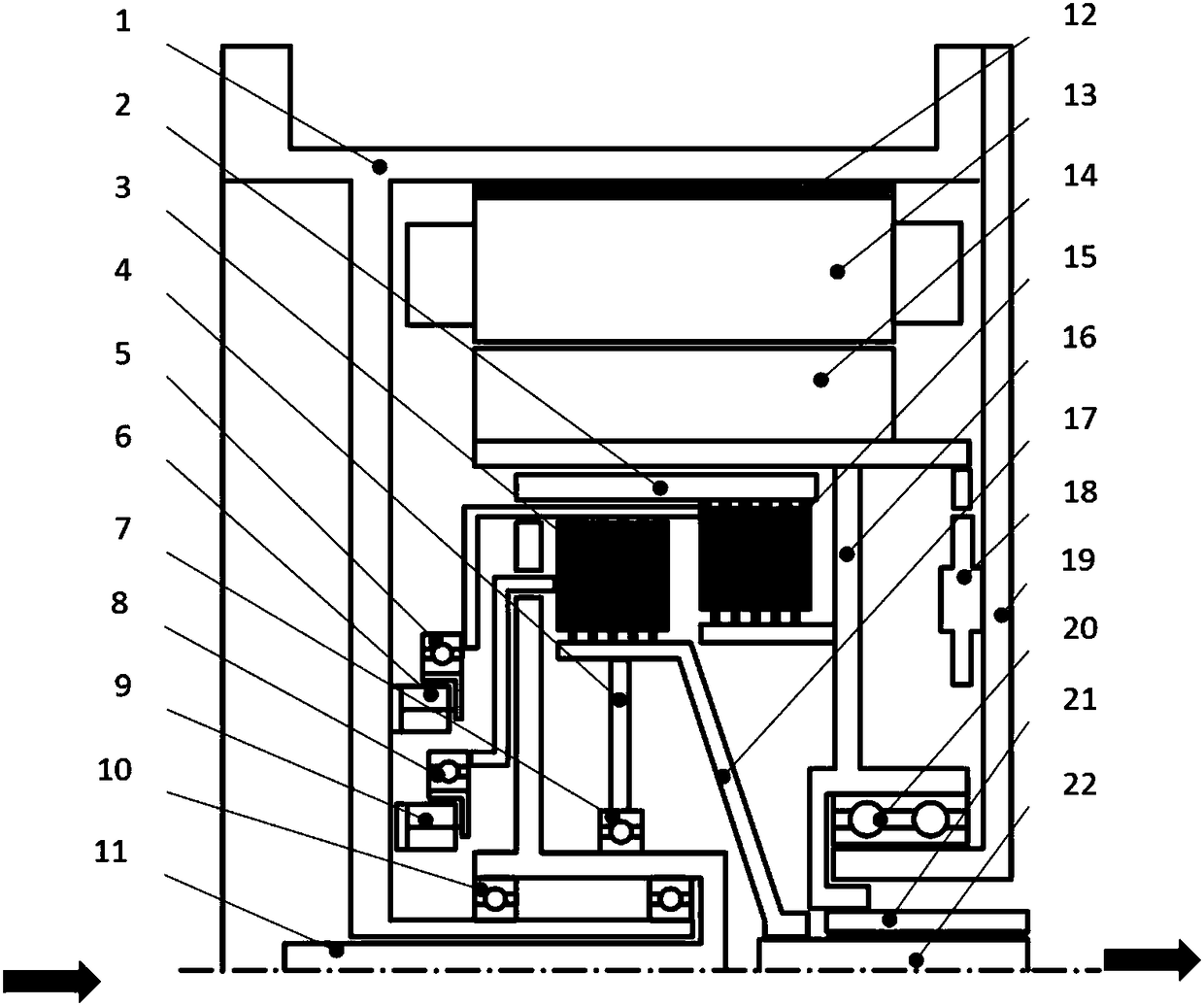

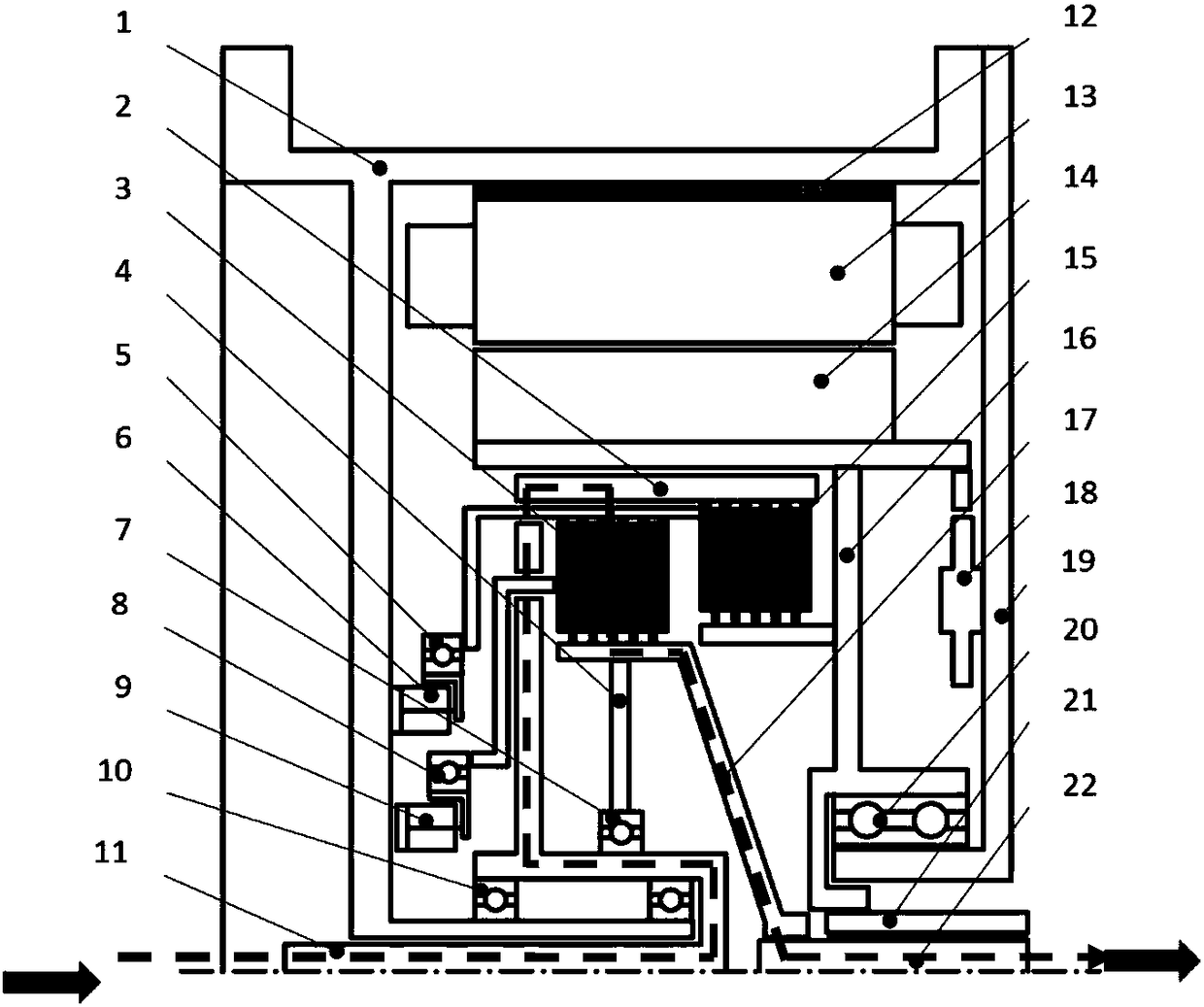

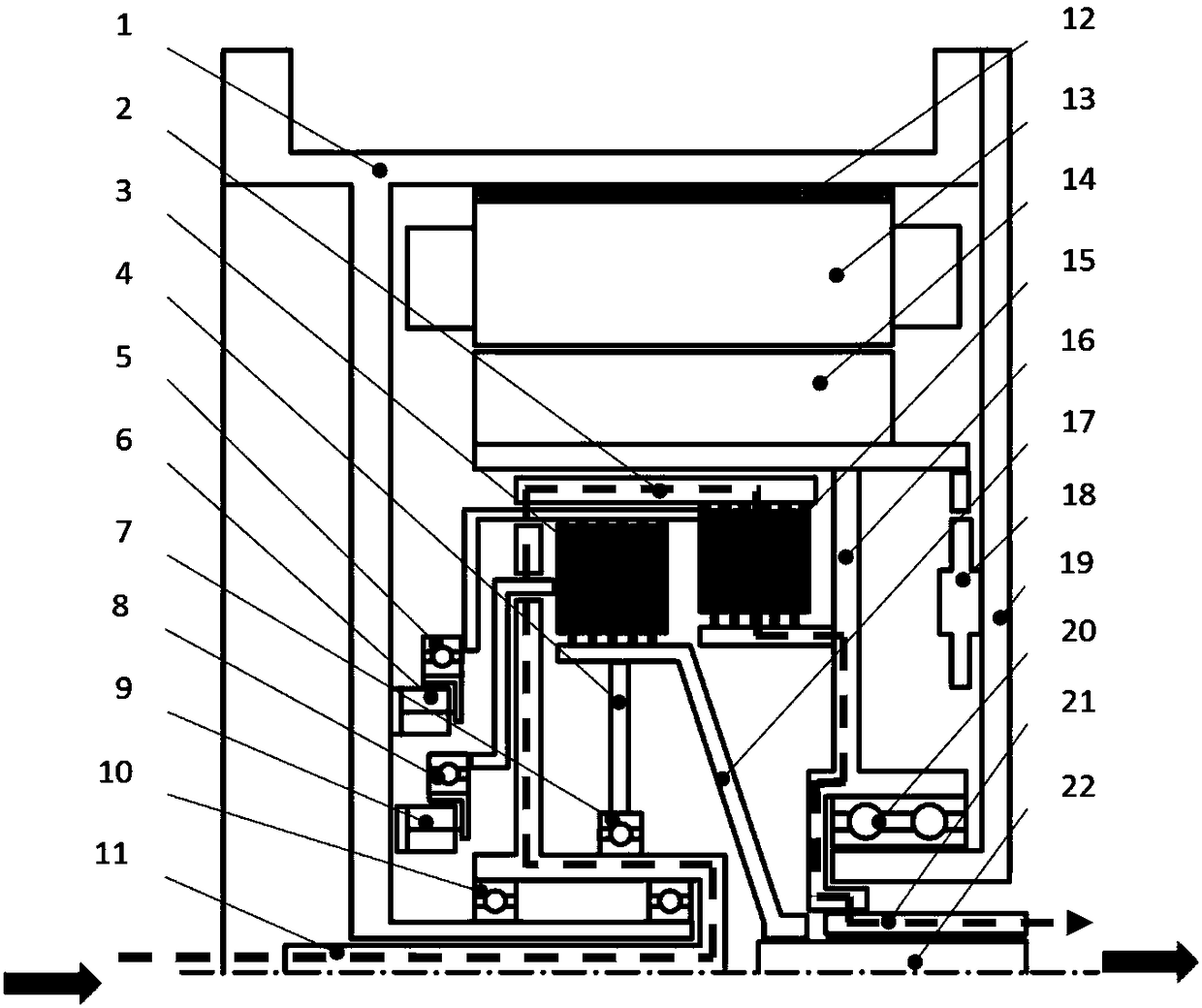

[0029] figure 1 Shows a hybrid power module according to an embodiment of the present invention. In this embodiment, the hybrid power module mainly includes a motor, an input end 11, a first output shaft 22, a second output shaft 21, a first clutch 3, a second Clutch 15 and housing 1.

[0030] The motor includes a stator 13 and a rotor 14 and is of the inner rotor type, that is, the rotor 14 is arranged radially inside the stator 13 . In this case, the stator 13 preferably has at least one electromagnetic coil and the rotor 14 has at least one permanent magnet. Furthermore, a cooling jacket 12 for the electric machine is arranged between the stator 13 and the housing 1 . The rotor bracket for transmitting the rotor torque is fixedly connected with the rotor 14 and is located at the radial inner side of the rotor 14 . The rotor support is also fixedly connected to the second flange 16 , and advantageously, the rotor support and the second flange 16 are designed as one body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com